KITAGAWA INDUSTRIES‘ Thermal Management Materials Meets Miniaturized and Faster Electronic Devices Needs

As electronic devices are becoming more miniaturized and faster, heat issues are put in the spotlight; the devices create high-temperature environments due to high-density design and continuous use. KITAGAWA Industries thermal management products help to lower temperature by conducting and insulating heat, resulting in better performance stability, and durability.

KITAGAWA Industries proposes suitable products with optimal materials, functions, and characteristics according to customers’ requirements and needs.

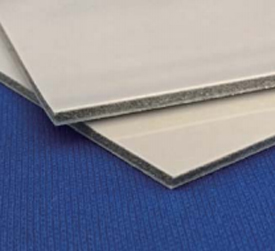

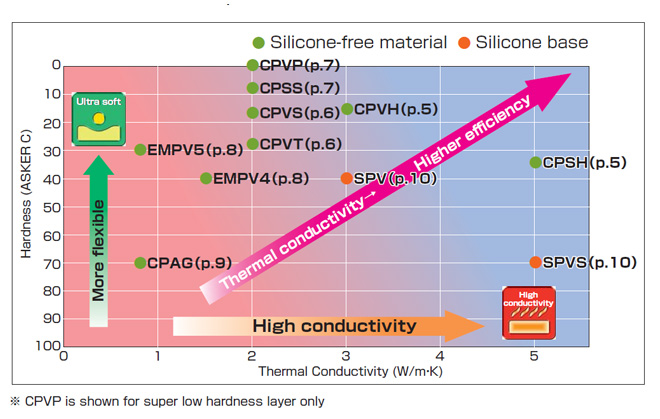

KITAGAWA Industries offers many kinds of Thermal management materials that have different features. Four Thermal pads are introduced here.

1. Non-Silicone Ultra-Low Hardness Type CPSS

<Features>

· Very soft thermal pad despite being non-silicone

· The pad has excellent adhesion due to good flexibility and stress relief, and therefore it can lower contact resistance.

· It uses non-silicone and creates no siloxane outgassing.

· Unlike silicone pads, the silicone-free pad bleeds hardly any oil and rarely causes problems to peripheral components.

<Applications>

In-vehicle, communication, and AV equipment

<Challenges>

Sometimes, a higher compression ratio of the thermal pad is required due to the components’ dimensional tolerances and gaps between units. However, if the pad has poor flexibility, loads on the heat-generating elements and printed circuit boards (PCBs) are large and may cause device malfunction. In addition, if object surfaces are not even, multiple thermal pads having different thicknesses may be necessary.

<Benefits>

KITAGAWA Industries products have excellent flexibility and stress relief and make the loads lower than the conventional thermal pads. (Since CPSS has high-stress relaxation, it is possible to increase the compression ratio, which allows high dimensional tolerances.)

<Non-silicone ultra-low hardness product>

· COOLPROVIDE (Both side tacky)/CPSS

· COOLPROVIDE (One side tacky)/CPSS-F

2. Non-silicone Highly Thermally Conductive Type CPVT, CPVH

<Features>

· Although it is a non-silicone high-thermal conductivity pad, the hardness is low.

· No siloxane gas is created and less likely to bleed oil compared with silicone type, and rarely causes problems to peripheral components.

<Applications>

In-vehicle, communication, AV and medical equipment, machine tools

<Challenges>

Conventional electrically insulating thermal pads usually have insufficient heat transfer.

High thermal conductivity pads have poor flexibility and stress release.

<Benefits>

KITAGAWA Industries products can lower contact thermal resistance since they possess both high thermal conductivity and low hardness.

<Non-silicone highly thermally conductive product>

· COOLPROVIDE/CPVT

· COOLPROVIDE (Both side tacky)/CPVH

· COOLPROVIDE (One side tacky)/CPVH-F

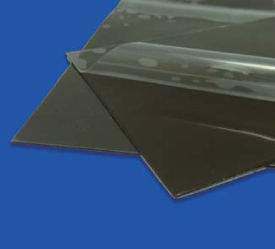

3. Non-silicone Composite Type EMPV

<Features>

· The thermal pad handles both thermal and EMC management. While having the same features as KITAGAWA Industries non-silicone thermal pads, it also suppresses electromagnetic (EM) waves with high magnetic permeability.

<Applications>

In-vehicle and communication equipment, LCD TV

<Benefits>

KITAGAWA Industries unique product helps to solve heat and EMC management issues. The pad can be utilized in limited internal spaces of equipment.

<Non-silicone composite product>

· COOLPROVIDE/EMPV4

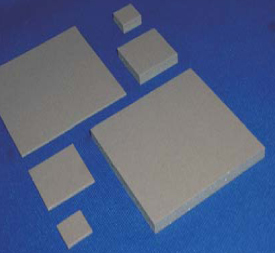

4. Ceramic Heat Sink CECD

<Features>

· The heat sink is made of porous ceramic.

· Porous materials have large surface areas and excellent thermal emissivity even compared to metals, resulting in good heat dissipation.

· Around 30% lighter than aluminum

<Applications>

Communication equipment, electrical appliances

<Benefits>

Metal heat sinks may radiate EM waves, however, ceramics are insulators and radiate no EM waves.

<Ceramic heat sink product>

· CERACOLD/CECD

Thermal Solutions of KITAGAWA INDUSTRIES

More innovative, clean, and precise

As society and industrial structures change and develop at a dizzying pace, new technologies and functions bring the potential to drastically change KITAGAWA Industries way of life and values.

In 1984, KITAGAWA INDUSTRIES developed EMC components and early on proposed solutions to EM wave problems.

Since then KITAGAWA Industries have been providing advanced technologies and services in a wide range of fields, including new energy, engineering machinery, automobiles, biotechnology, IT, semiconductors, and medicine etc.

Together with KITAGAWA Industries clients, KITAGAWA Industries will continue to look ahead to accelerating technological innovation and aim for better products, more efficient production systems, and more innovative manufacturing.

- +1 Like

- Add to Favorites

Recommend

- Bencent Electronics Took Part in 2023 China Power Supply Society

- Thermal Grizzly CPU Contact Frame Intel 1700 LT is Now Available

- Thermal Grizzly Product Update: AM5 High-Performance Heatspreader with New Nickel Plating

- Thermal Grizzly Prepared Four New Products for Intel’s Arrow Lake Processors

- Reusable Waermtimo Thermal Pads and Thermal Gel without Solvents Are Excellent Solutions to SmartWatch Heat Dissipation

- Advantages of Carbon Fiber Thermal Pads over Silicone Thermal Pads

- Waermtimo WT5912 and WT5902 Series Thermal Pads Tightly Integrate Irregular or Complex Surfaces, Suitable for Wireless Routers

- Why Do Carbon Fiber Thermal Pads Become The Newest in Thermal Interface Materials?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.