Reusable Waermtimo Thermal Pads and Thermal Gel without Solvents Are Excellent Solutions to SmartWatch Heat Dissipation

When it comes to smart wearable devices, the most popular may be smartwatches. Currently, smartwatches on the market are mainly divided into two categories: health data monitoring and smart experience. Health data monitoring products usually have heart rate, pedometer, and calorie consumption monitoring functions, while smart experience watches focus on the application experience on the wrist. For example, the Apple Watch plays a good role as the second screen of the iPhone.

The outstanding performance of the Apple Watch is due to its powerful internal nature.

Numerous components are compactly distributed in a small space:

Red: Anhuake AFEM-8087

Orange: OU JQ

Yellow: YY MEH ECE (acceleration sensor + gyroscope)

Green: AE827 I2033 0836

Blue: STMicroelectronics ST33G1M2 32-bit MCU with ARM SecurCore SC30

The third-party APP for Watch has already exceeded 1000+. As the Apple Watch updates iterative calculations, it becomes more advanced and smarter, and the product's functions will definitely be more and more. The load on the chip or processor will also be very large, and the heat generation will increase accordingly. Whether the heat generated during chip operation can be conducted out at the first time, higher requirements are also placed on the requirements of heat-conducting and heat-dissipating materials.

【Solutions 01】

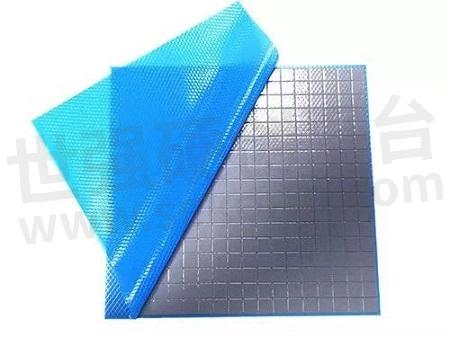

WT5912 series thermal pad

Model: WT5912-H20-55; WT5912-H25-40

Waermtimo researched and developed TIM's new high-strength thermal pad, which is a thermal sheet with high mechanical strength, elongation rate> 300%, high toughness, effective vibration absorption while conducting heat, and can be reworked many times. Continuously, it can tightly integrate irregular or complex surfaces, has excellent interface filling, and can be used repeatedly. Temperature resistance range -50 ~ 200 ℃, applicable to a wide range of power equipment, automotive electronics, communication equipment, network terminals, storage devices, handheld, wearable, and mobile terminal products between the internal chip and the radiator, this type of pad can be used to solve the problem of heat conduction and heat dissipation. At the same time, it can also be applied to the housing of some electronic products, which has the functions of heat dissipation, insulation, dust resistance, and water resistance.

【Solutions 02】

WT5902 series thermal pad

Model: WT5902-D40-40; WT5902-D45-40

Thermal conductivity range: 4W, 5W, 6W, 7W, 8W

WT5902 series thermal pads can solve the problem of product structure design tolerance changes and can be reused. They are good vertical heat transfer materials between the heat source (CPU or electronic chipset) and the heat sink. Have good insulation and mechanical properties, can tightly integrate irregular or complex surfaces, are easy to use, and are easy to remove. They are widely used in power supply equipment, automotive electronics, communication equipment, network terminals, storage devices, consumer electronics, and other fields.

【Solutions 03】

WT5921 series thermal gel

Recommended models: WT5921-30; WT5921-35

Thermal conductivity range: 3W, 3.5W

The thermal gel is generally packaged with a syringe. This material itself does not contain solvents. It has the characteristics of high thermal conductivity, low compression force, high compression ratio, good electrical insulation properties, and good temperature resistance. Good weather resistance, high and low temperature resistance, good insulation properties, etc. At the same time, it has strong plasticity, can meet the filling of uneven interfaces, and meet the heat transfer requirements of various applications. It is currently the most advanced thermally conductive material.

- +1 Like

- Add to Favorites

Recommend

- Waermtimo WT5912 and WT5902 Series Thermal Pads Tightly Integrate Irregular or Complex Surfaces, Suitable for Wireless Routers

- Waermtimo’s New WT5912 Series Thermal Pad with High Mechanical Strength and Elongation Rate over 300% Can be Used for iPadPro Heat Dissipation

- Waermtimo Provides Professional Thermal Conductivity Solutions to 5G Device Heat Dissipation

- Waermtimo High-Strength Thermal Pads Help PCB Conduct Heat Effectively

- Thermal Pad WT5912-H20,WT5912-H25 Provides a Heat Dissipation Solution for Wireless Charger

- Waermtimo’s High-Strength Thermal Pads Help LED Projectors Dissipate Heat More Effectively

- Why Thermal Gel Become More and More Popular?

- Waermtimo, a New Composite Cooling Material Supplier, Anounced a Distribution with Sekorm to Enrich Carbon Fiber Thermal Conductive Materials and More

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.