Why Thermal Gel Become More and More Popular?

The thermal gel is a kind silicone two-component paste-like thermal conductive filling material. It mainly meets the requirements of low pressure and high compressive modulus during use. It can realize automatic production. It has the properties of excellent contact with electronic products, low contact heat resistance, and excellent electrical insulation. This material has the advantages of thermal pad and thermal grease, while at the same time better compensating for the shortcomings of the above two materials.

The thermal gel has the advantages of good affinity, weather resistance, and good insulation performance. At the same time, it has strong plasticity, can meet the filling of uneven interfaces, and can meet the heat transfer requirements of various applications. It has the characteristics of high thermal properties, low compression force, high compression ratio, good electrical insulation performance, and excellent temperature resistance, which can be used automatically.

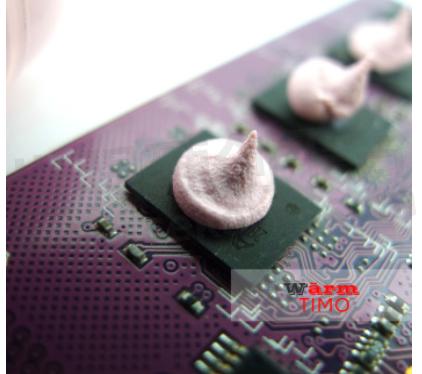

Fig.1

Thermally gel is typically packaged in syringes that are inherently solvent-free. It is currently the most advanced thermal conductive material, and suitable for robotic automated assembly lines.

1. Thermal gel has the advantages of high thermal conductivity, ultra-low thermal resistance, no need for heat treatment, convenient construction, etc.

2. It has the same plasticity as plasticine and is easy to match with product designs with large variations in thickness.

3. Will not deform when static usage after molding, excellent anti-aging performance.

4. Low-stress, low-modulus thermal conductivity products

5. Self-adhesive, no need to use additional adhesive products

6. Excellent high-temperature resistance, weather resistance, radiation resistance, and excellent dielectric properties

7. Superior chemical and mechanical stability

8. Store at room temperature and have low storage costs.

Fig.2

What else advantages does the thermal gel have?

1) Ultra-low thermal resistance of thermal gel to optimize heat dissipation of products

2) Convenient for R&D and design. Since the thermal gel is paste-like and permanently self-adhesive, there is no need to especially consider the product size and tolerance limits in the product design, and it can be flexibly used according to the best design effect.

3) Convenient procurement management, thermal gel is packed in the syringe, and one model specification can meet the needs of multi-machine and multi-products, greatly simplifying procurement management and warehouse management

4) The thermal gel process is automated, and the syringe package can be automatically dispensed, which greatly improves engineering efficiency, reduces labor cost and time costs, and optimizes the stability of the product.

Based on the advantages of high deformation, high thermal conductivity, and high insulation, the thermal gel is widely used in: Robotic automation assembly, automotive industry, communication industry, ABS system, LED chip, communication equipment, mobile phone CPU, memory module, power module such as IGBT, power semiconductor field, etc.

Waermtimo WT 5921 thermal gel is made of silicone, adding thermal conductive filler and bonding material in a certain proportion, and processed by a special process. It has excellent weather resistance, radiation resistance, and superior dielectric properties.

- +1 Like

- Add to Favorites

Recommend

- Leading Electronic Products into a Direction, 0.2mm Ultra-thin High Thermal Conductivity Pad from Waermtimo

- Waermtimo, a New Composite Cooling Material Supplier, Anounced a Distribution with Sekorm to Enrich Carbon Fiber Thermal Conductive Materials and More

- Waytronic Has Developed the Escalator Safety Voice Prompt Device for Occasions with Potential Safety Accidents

- Waytronic Infrared Human Body Induction Voice Horn with External Trigger and Relay Functions

- Waermtimo Provides Professional Thermal Conductivity Solutions to 5G Device Heat Dissipation

- Waytronic Intelligent ForestFireproof Voice Prompter Can Replace Traditional Safety Signs

- Waermtimo High-Strength Thermal Pads Help PCB Conduct Heat Effectively

- Waermtimo Silicone Grease with Good Thermal and Insulating Properties Is Ideal for Computer CPU Cooling

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.