Advantages of Carbon Fiber Thermal Pads over Silicone Thermal Pads

Traditional silicone thermal pads are composed of silicone oil (silicone resin), adding thermal conductive ceramic powders such as alumina, aluminum hydroxide, boron nitride, silicon carbide, etc. or metal powders such as copper, aluminum, silver, etc. Solid oxide is generally used as its powder, if it can be made into whiskers, its thermal conductivity will be greatly improved. The lamellar structure of graphite makes its thermal conductivity anisotropic. The thermal conductivity and electrical conductivity of ideal graphite along the direction of the crystal layer can be several to dozens of times greater than that perpendicular to the direction of the layer. However, due to its lamellar structure, it cannot form good packing like spherical particles, so its filling volume is relatively limited.

For spherical thermally conductive fillers, although the thermal conduction paths are not easy to form, they are relatively easy to accumulate, especially the smaller particles fill the gaps between the larger particles, forming a denser accumulation, thus forming more thermal conduction paths, so as to prepare composite materials with higher thermal conductivity.

Due to a certain length-to-diameter ratio (long strip, filament), carbon fiber is easier to form a heat conduction path and has higher strength. Adding it can improve the heat conduction and mechanical properties of rubber. However, fibers, whiskers, and dendritic thermally conductive fillers all have fixed thermally conductive orientations. In order to obtain higher thermal conductivity and filling capacity, the mixing process and the molding process of the gasket need to be specially designed.

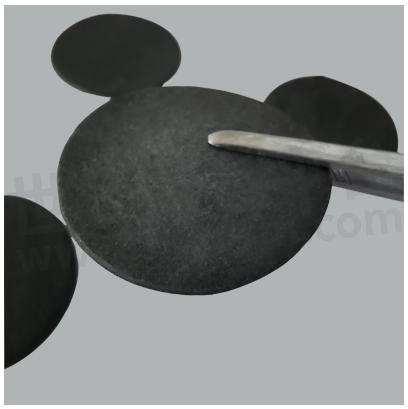

At present, the highest thermal conductivity of SHEEN's carbon fiber thermal pad CSF series has reached 45W/mK, while the thermal conductivity of the more mature high thermal conductive silicone pads on the market is 12W/mK, and the CSF series has a lower density than traditional thermal conductive silicone pads, low precipitation, non-sticky, better mechanical properties and other advantages. Provide high-reliability heat dissipation protection for portable smart devices, high-end electronic products, high-heating power components, etc.

- +1 Like

- Add to Favorites

Recommend

- How to Choose Thermal Silicone Pad? Sheen Helps You Solve the Selection Problem

- Sheen SF series Thermal Silicone Pad: Heat Dissipation Solution for DC Equipment MOS Shielding Cover

- Sheen‘s Thermal Silicone Adhesive Film Is Installed Using 7 Steps

- How Thin Is The Thermal Conductive Silicone Pad

- Selection of Thermally Conductive Silicone Pad

- Is the Poor Performance of the Radiator a Problem with the Thermal Material?

- What Does the Thermal Resistance of Thermal Conductive Materials Affect?

- Application of Thermal Conductive Materials in Charging Piles

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.