ATP‘s Fastest “Industrial Only” DDR4-3200 DRAM Modules with the Transfer speed of up to 3200MT/s

Transfer speed of up to 3200MT/s optimizes the latest high-performance Intel & AMD platforms.

Systems are running faster and processing data more rapidly, thanks to the improved performance of the latest-generation processors. As CPUs become faster, they also need faster memories. Taking full advantage of the AMD EPYC™ Family and 2nd Generation Intel® Xeon® Scalable Processors (formerly codenamed Rome and Cascade Lake, respectively) are ATP Electronics' DDR4-3200 solutions, which are also ready for future AMD Milan and Genoa as well as Intel® Cooper Lake and Ice Lake processors.

How does ATP’s DDR4-3200 deliver a memory boost to these high-performance platforms and provide accelerated performance for embedded applications requiring speed, endurance, and reliability?

Performance Boost with Higher Interface Speed, Module Density, and Peak Transfer Rates

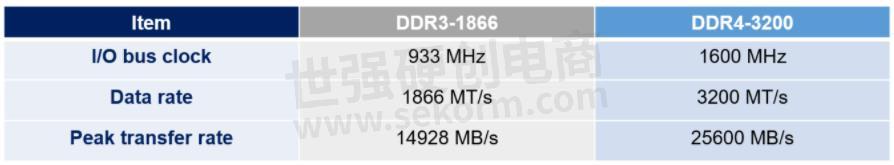

ATP DDR4-3200 DRAM modules can operate at the same speed even at full load. With the increased interface speed from 2666/MTs to 3200 MT/s, they amplify theoretical peak performance by up to 20%. They transfer data about 70% faster than DDR3-1866, one of the fastest DDR3 versions available.

Enterprise-level densities reach up to 128GB — a big leap from DDR3's 32 GB capacities. Peak transfer rates up to 25,600 MB/s dramatically increase the capabilities of growing embedded and cloud computing environments to meet large-scale, memory-intensive, and diverse (I)IoT/AI workloads.

Table 1. shows a comparison between DDR3-1866 and DDR4-3200.

Figure 1. compares the performance of DDR3-1866 and DDR4-3200.

Better Energy Efficiency with Low-Power Design

Consuming only 1.2V compared with DDR3's 1.5V or 1.35V, DDR4-3200 allows operation at higher speeds without higher power and cooling requirements. Better energy efficiency translates to lower consumption and substantially higher savings. By implementing the fastest and low-power IC design, ATP DDR4-3200 modules enable cost-effective scalability and expansion of memory footprints to keep pace with future requirements.

Ideal for HPC Applications

ATP DDR4-3200 solutions are best suited for high-performance computing (HPC) applications requiring high density, low power, great scalability, and efficiency, such as:

Telecommunication infrastructures

Networking storage systems

Network-attached storage (NAS) servers

Micro/cloud servers

Embedded systems (e.g., industrial PCs)

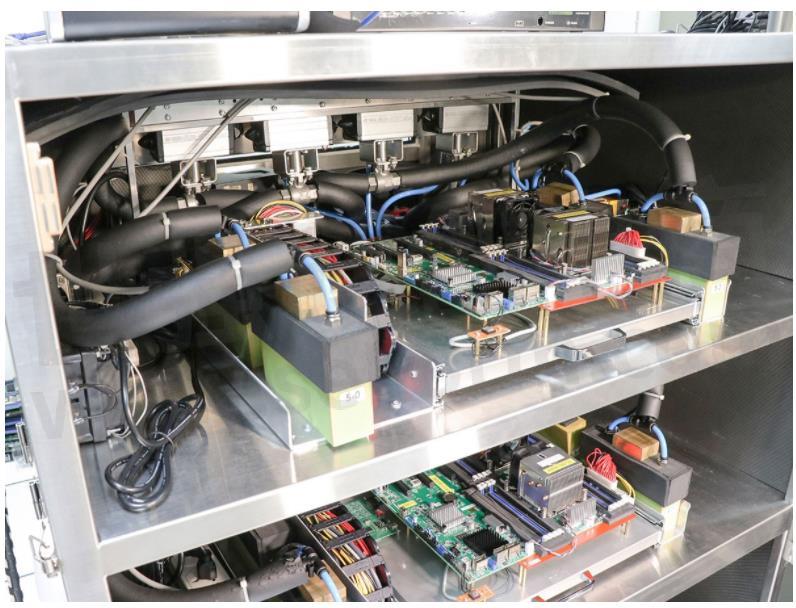

Module-Level TDBI for Extreme Reliability in Extreme Environments

ATP DDR4-3200 DRAM modules with wide-temperature ICs perform reliably in harsh environments, including extreme temperatures from -40℃ to 85℃. ATP implements module-level tests during burn-in (TDBI) to expose weak modules and detect and screen out even 0.01% error, thus ensuring utmost module reliability and long-term endurance.

The ATP TDBI system applies extreme high/low temperature, high-low voltage, and pattern testing on DRAM modules. The system consists of:

The miniature chamber isolates temperature cycling only to the module being tested so as not to thermally stress the rest of the testing systems. This minimizes the failure of other testing components, such as the motherboards. In conventional large thermal chambers, the failures of non-DRAM-related testing components are constant given that the whole system is thermally stressed.

Module riser adapters from the motherboard, which allow easy module insertions in production-level volumes

Multiple temperature sensors, which regulate temperature profiles, operate on a wide testing temperature range of -40℃ to 95℃.

Available Configurations

ATP unbuffered DDR4-3200 modules are available in the following configurations: SO-DIMM, UDIMM, ECC UDIMM, ECC SO-DIMM, and RDIMM.

- +1 Like

- Add to Favorites

Recommend

- ATP Rapid Diagnostic Test (RDT): Accelerating Failure to Maximize Reliability and Endurance

- News | NAND Flash Storage Solutions for the Data-Driven 5G Era | ATP

- ATP Electronics’ Latest pSLC Embedded SSDs Offer Best TCO with Customizable Endurance

- The ATP Gym and Coach System: Exercising SSDs to Ensure Total Fitness

- ATP‘s PCB Assembly Solderability Validation Tests

- New Die Package Extends 3D TLC e.MMC Endurance to MLC/SLC Levels of ATP E750Pi/Pc, E650Si/Sc Series e.MMC

- DDR4-3200 DRAM Solutions Deliver Memory Boost to AMD EPYC™ and 2nd Gen Intel® Xeon® Scal | ATP

- How ATP Protects Your Data and SSDs with HW/FW Power-Loss Protection

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.