ATP Rapid Diagnostic Test (RDT): Accelerating Failure to Maximize Reliability and Endurance

Coffee brewing is undoubtedly both an art and a science. Coffee enthusiasts go to great lengths to judge the perfect cup of coffee based on its taste, aroma and flavor. The quality of beans, where they were grown, how they were roasted, and even how they were ground all play important roles in making sure that a cup of coffee is up to par with a sommelier’s standards.

Interestingly, not all beans that go into each cup of coffee are of the same quality; yet, with the right processes and techniques, they can altogether make a satisfying drink. The same is true with integrated circuits (ICs) in a NAND flash storage device, such as a solid state drive (SSD), memory card or e.MMC.

Considering the quality variance, how can a manufacturer make sure that the device performs reliably throughout its guaranteed lifespan?

Beginning at the End

At ATP Electronics, it all starts with the end in mind. The reliability journey is a long and complex process, but for this article, we will try to simplify it with these steps.

1. Evaluate the application data usage workload.

Discussions with the customer will determine what the storage device will be used for, under what operating environments it will be used, what physical and electro-mechanical challenges it is expected to face, and other relevant factors. At this stage, endurance ratings based on drive rates per day (DWPD) and operational temperature range will be established.

2. Select a suitable NAND flash type.

ATP offers a complete line of NAND flash options that the customer can choose from to make sure that the building blocks of the storage device are right for the application. Depending on the desired endurance ratings, expected service life, capacity, and other considerations, ATP can help the customer select the most appropriate NAND flash. ATP’s portfolio includes both 2D (planar) or 3D NAND configured as single-level cell (SLC), multi-level cell (MLC), triple-level cell (TLC), or pseudo SLC (pSLC).、

3. Perform Rapid Diagnostic Test (RDT).

After the storage device is assembled with the selected NAND, it is then put through a stringent screening test. This step is similar to simulating a thunderstorm/heatwave within the device, to test whether it can meet the client's requirements. At ATP, we call this process Rapid Diagnostic Test or RDT, where 100% screening is done on every device and in every area of the drive with ATP’s self-built proprietary tester.

RDT: Ensuring Extra Robust Flash Storage

Some people like their coffee strong, robust, and concentrated like espresso. In industrial applications where supreme reliability and extended endurance are paramount, ATP RDT is the best way to deliver extra robust flash storage.

ATP RDT’s main goal is to accelerate the failure of weak NAND flash blocks so that only the most robust will remain on the device, thus maximizing reliable performance and endurance. RDT helps make sure that ATP products can endure extreme temperatures and harsh operating conditions.

At the outset, this appears to be an ironic process. To the untrained eye, this may not make sense. But the truth is, it is the key to delivering the highest-quality flash storage products for mission-critical applications.There are many parameters tested under RDT, but for simplicity's sake, this article will highlight the two most important elements — error correction code (ECC) & temperature.

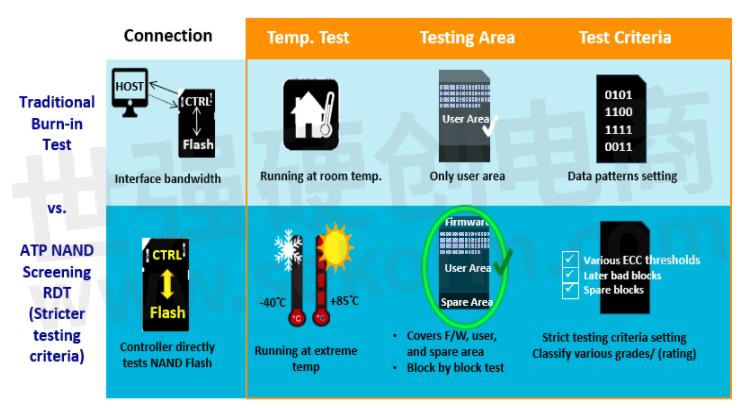

Figure 1. ATP-designed/built RDT process allows for direct and 100% NAND flash screening

Figure 2. ATP e.MMC devices are loaded into a specially designed RDT chamber for thermal cycling tests at both low (-40°C) and high (85°C) temperatures. ATP can perform high-volume testing according to customer request.

The ATP Advantages

1. RDT at Room and Extreme Temperatures: Challenging the Strength of the ECC

Other module houses only test at room temperature (25°C), which does not rigidly screen the NAND nor tests the true strength of the ECC. As a result of the relaxed criteria, fewer errors are identified because there’s not much ECC performance difference for strong and weak blocks. This causes the weaker blocks to be hidden behind the ECC.

As these weaker blocks have not been marked as “unsuitable,” data will be unknowingly written onto them. On the field, they will also be exposed to temperature challenges, ultimately compromising the reliability of the device and causing early life failure.

ATP’s RDT requires thermally stressing 100% of the drive at both room temperature (25°C) and at extreme ranges from -40°C up to 85°C, where more errors will appear. This challenges the strength of the ECC and pressures it to correct more errors.

As the ECC correction threshold is reached, more weak blocks can be marked as “unusable” or “uncorrectable.” In actual use, data will be written only on the robust blocks and the drive will be able to withstand harsh temperature ranges on the field. This minimizes early life failures, extends device endurance, and ensures the reliable operation of the device during its entire service life.

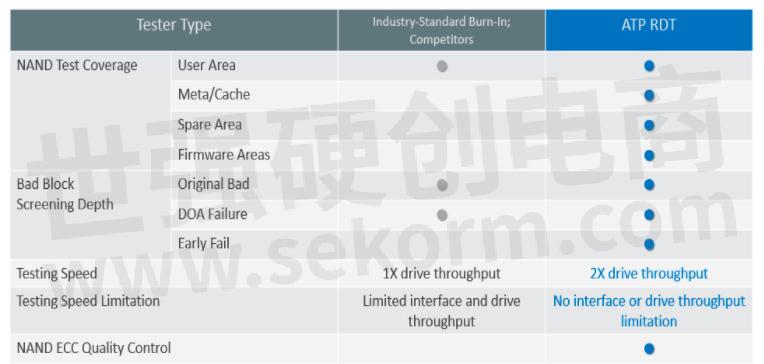

2. RDT Beyond the User Area: 100% Screening

Most module houses also typically test only the user area. ATP tests the entire drive, including user, meta/cache, spare and firmware areas.

3. RDT’s More Stringent Criteria: Thorough Screening and Accurate Ratings

This screening process does not only weed out defective components to prevent early life failures. It also detects later bad blocks, thus allowing ATP to accurately rate and classify various product grades for application-specific requirements. The process makes sure that all ATP products will deliver superior and reliable performance within their guaranteed lifespan.Moreover, ATP’s RDT is directly performed by the controller on the NAND flash. This speeds up the testing process by eliminating system bandwidth limitations.

The figure and comparison table below summarize the advantages of ATP's RDT.

Figure 3. Advantages of ATP’s RDT over traditional burn-in tests.

Table 1. Comparison table between competitors’ standard burn-in tests and ATP’s RDT.

Conclusion

Like coffee beans, quality variance in NAND flash blocks comprising a storage device is a reality that we at ATP Electronics need to contend with. Industrial applications require storage to be robust, reliable and long-lasting so as not to compromise operations and to make sure that investments are worth the total cost of ownership (TCO).

By using stress accelerants such as temperature, RDT identifies qualified and unqualified blocks intended for specific applications, so customers can rest assured that the flash storage device will not fail before its specified end of life across the industrial temperature range and across various embedded/industrial usage cases.

Knowing that the ATP flash storage devices are reliable and enduring, customers can relax and enjoy their cup of coffee.

For more information on the RDT process and other testing capabilities, visit the ATP website or contact an ATP Representative.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.