Pulsing 1550nm Lasers for Lidar Driven by EPC‘s eGaN® FET Technology

Pulsed lidar systems typically use either 905nm or 1550nm Lasers for optical emission. Above 1400nm, various elements of the eye absorb the light, impeding it from reaching and damaging the retina. As laser power is increased, not all of it is absorbed, and at some point, retinal damage may occur. Since 905 nm light does not get absorbed, it does reach the retina, so care must be used to limit the energy density to prevent damage.

If the decision is to use 1550nm light, efficiency differences in the semiconductor laser make it necessary to use a higher current for the same optical power emitted compared with 905nm light. Additionally, the same characteristics that allow the light to be absorbed by the eye before getting to the retina cause it to be absorbed by the atmosphere. This phenomenon is amplified as humidity increases to fog, rain, or snow. The drive power required for a 1550nm laser may be up to 10 times higher than for a 905nm laser-based system. Fortunately, there is a solution to deliver the power necessary to drive 1550nm lasers while maintaining the edge speed and pulse required for high resolution in pulsed lidar applications.

EPC’s eGaN® FET technology has the ability to drive a wide range of pulse currents in very short times using small, inexpensive circuitry. The range of technology is from amps to hundreds of amps, all capable of pulse widths from 1 ns to 5 ns using power devices rated from 15V to 200V.

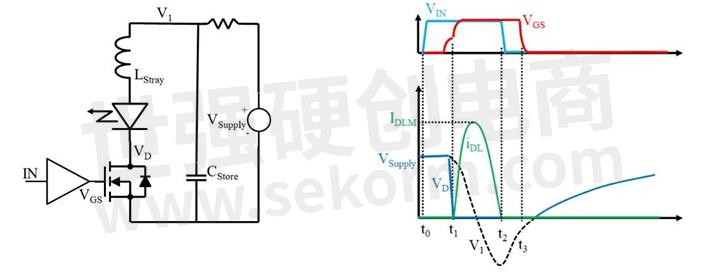

Resonant discharge is typical for high power direct time of flight (DToF) where a capacitor is charged, and then the laser driver discharges it into the laser. The resonant frequency is derived primarily from the power storage capacitance and the stray inductance as 1/(2π√LC). With CStore and LStray fixed, peak power is a function of capacitor voltage. The image below shows the basic circuit and the basic waveforms.

For high power, while maintaining a narrow pulse width, a 160V source can be used. EPC2034C is a 200V device that is capable of a peak current of over 213A. eGaN technology has ultra-low capacitance and its wafer-level packaging making it ideal for high-speed pulsed lidar systems. Waveforms for the EPC2034C show a peak current of 221A with a full width at half maximum (FWHM) time of 2.9ns.

Upcoming work expects to show a pulse of > 300A with an FWHM of < 5ns. This work will use the 100V EPC2032 off an 80V bus.

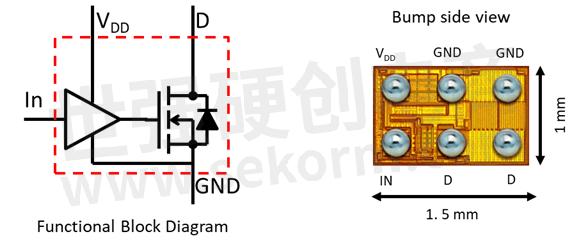

In addition to discrete eGaN FETs being driven by silicon integrated circuit gate drivers, EPC has introduced eToF™ laser driver ICs. The first products have 40V, 10A capability, and are monolithically integrated using EPC’s standard eGaN process. EPC21601 uses 3.3V input logic, while the EPC21603 uses an LVDS receiver. Both require a 5V logic supply. These laser drivers are fast, small, and cost-effective solutions to both direct time-of-flight (DToF) and indirect time-of-flight (IToF) 3D cameras. A block diagram and an image of the bump side of the EPC21601 are shown below. These integrated laser drivers have the power capability to bring 1550nm lasers to IToF for short-range applications.

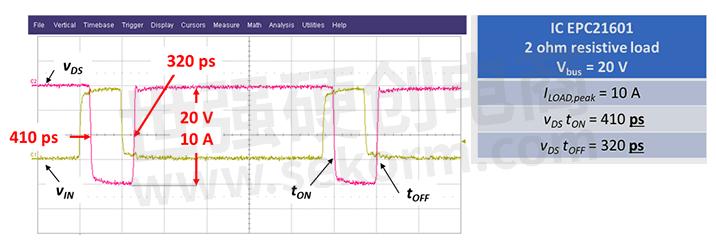

Results for the EPC21601 at 20V, 10A, using a resistive load, give a very impressive 410ps drain fall time at turn on and 320 ps drain rise time at the turn-off. Waveforms are shown below.

While 1550nm systems greatly improve eye safety, they have the fundamental challenge of requiring much more power than 905nm systems. eGaN FETs and eToF laser drivers solve the problem of powering them.

- +1 Like

- Add to Favorites

Recommend

- Sharge Selects GaN FETs EPC2218 from EPC for High-power USB PD Charger Retro 67 to Achieve the Most Efficient Power Conversion

- EPC Introduces The 40 V, 1.6 Milliohm EPC2069 EGaN® FET, it Can Range From 500 W to 2 KW and Exceed 98% Efficiency

- EPC Announces a New 3-phase BLDC Motor Drive Inverter Using the EPC2065 EGaN® FET

- EPC Launches 40V EPC2055 eGaN FET Ideal for High Power Density Solutions for USB-C Battery Chargers and Ultra-thin Point-of-Load Converters

- New Automotive Qualified GaN FETs EPC2204A and EPC2218A for Vehicle Electronics and Advanced Autonomy from EPC

- Efficient Power Conversion (EPC) Expands 100 V eGaN FET Family Offering Designers Best-in-Class Performance and Cost for 48 V DC-DC Conversion

- Design Higher Resolution Lidar Systems with New Automotive-Qualified GaN FET EPC2252 for Advanced Autonomy from EPC

- 65A ePower™ Chipset from Efficient Power Conversion (EPC) Redefines Power Conversion

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.