GaN Technology Drives Power Density in Data Centers

Many server designs are switching from rack-based 48V isolated, regulated DC-DC converters that convert to 12V, to non-isolated, unregulated 48V DC-DC converters mounted on the server boards. In this article EPC brings us to know something about the GaN technology.

Space on a server board is extremely precious, and servers – especially those designed for performing high-end computation functions such as artificial intelligence (AI) – are demanding more and more power. Simultaneously, GPUs are becoming quite common in AI systems. These GPUs are putting additional demands on power conversion requirements, where voltages as low as 0.6V are required under certain operating conditions. Requirements now routinely top 3kW per board with several systems requiring as much as 5kW.

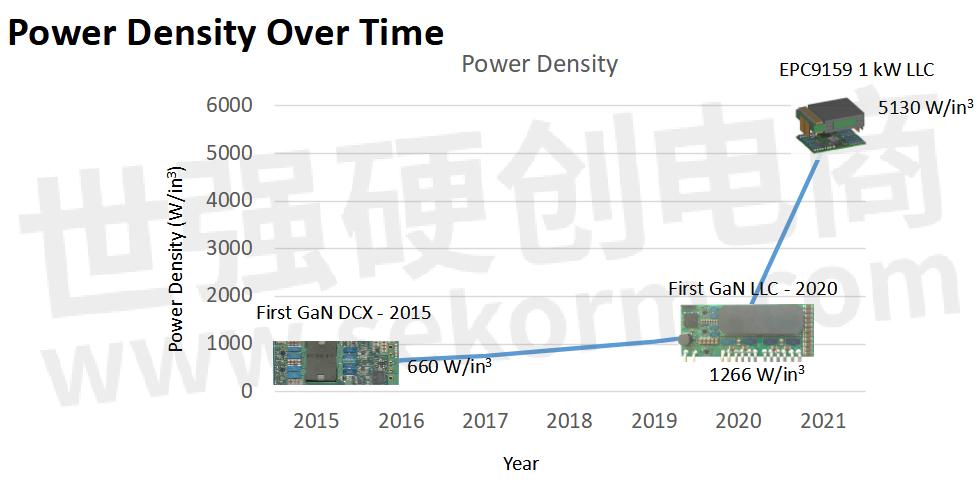

These stringent power requirements have necessitated changes in basic power conversion architecture. First, with board space at a premium, high power density architectures become the holy grail for power systems designers. eGaN FETs have been in production for 12 years, and the 5th generation devices have pushed the upper bounds of power density by almost a factor eight in the past six years as illustrated in figure 1.

Figure 1: GaN technology has increased power density of 48V–12V DC-DC converters by almost a factor of eight since 2015

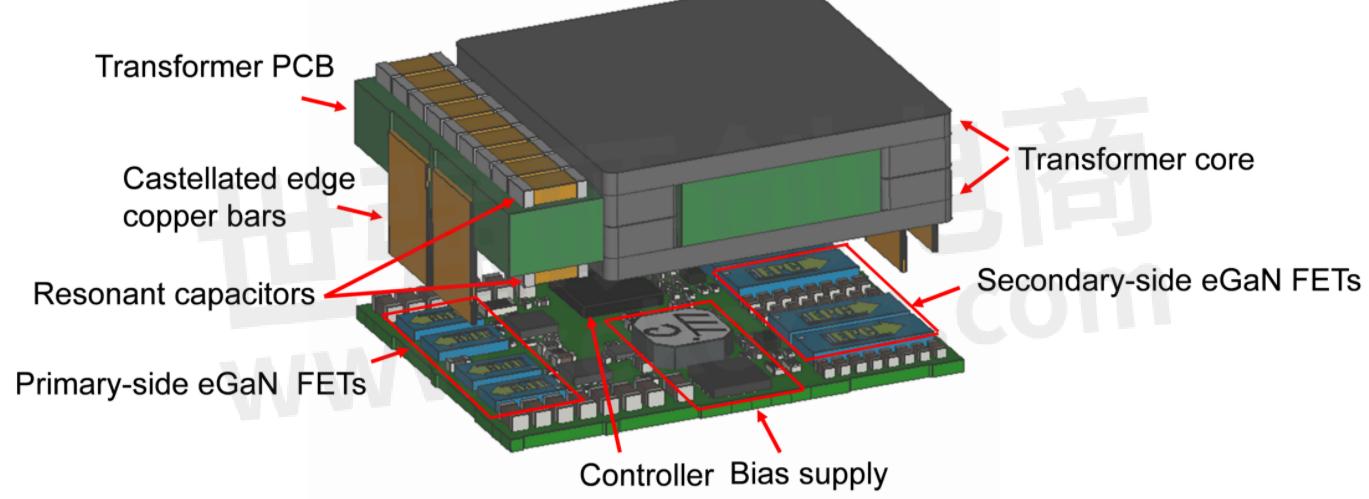

Advances in GaN technology, coupled with improvements in magnetics and thermal management, enabled this acceleration. The layout and physical architecture of the latest version of a 48 – 12V unregulated DC-DC converter is shown in figure 2. The use of all three dimensions to locate the transformer on top of the active circuit saves space as well as reduces resistive losses.

Figure 2: A 1kW 48V–12V LLC converter. It is 22.8mm x 17.5mm x 7.5mm and has a power density of 5130W/in3

A peak efficiency of 98 percent, coupled with excellent thermal management, enables this tiny converter measuring 22.8mm x 17.5mm x 7.5mm to deliver 1kW.

GaN Integration

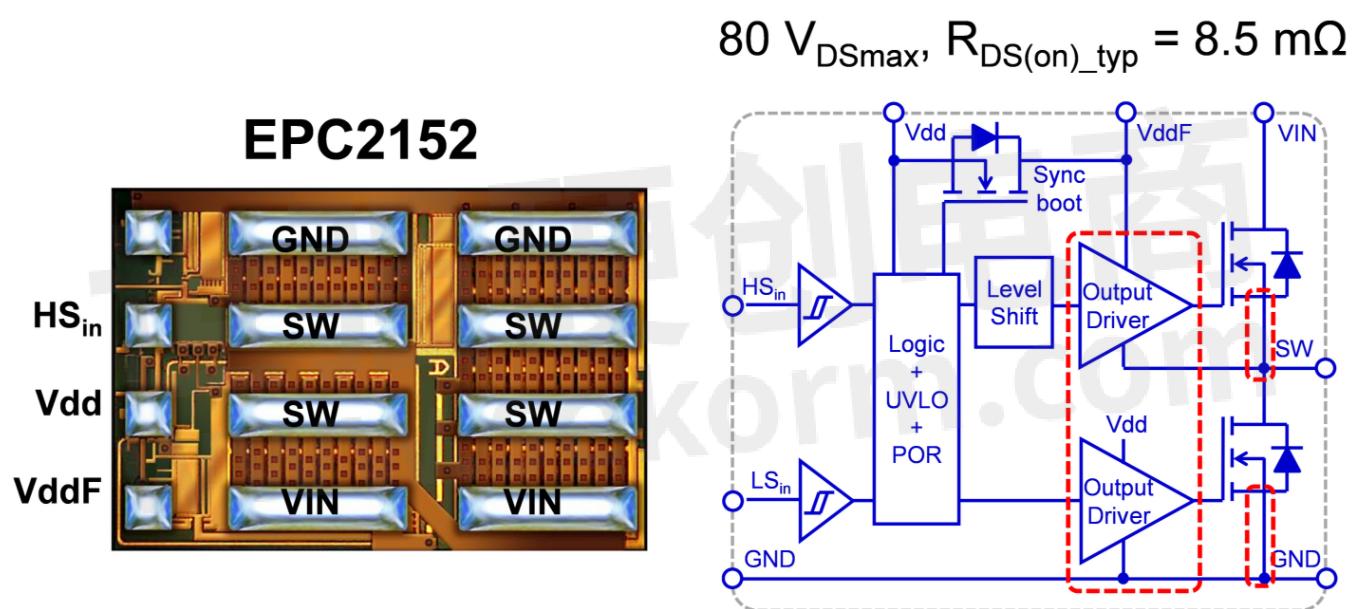

The next step for increasing power density is to incorporate recent advances using GaN to integrate additional circuit functions on a single chip. Shown in figure 3 is the EPC2152 monolithic power stage. On this single GaN-on-Si chip are integrated two power transistors, two drivers, a level shift circuit, a bootstrap circuit, and input logic. This GaN IC replaces three components and, by virtue of the higher performance realized through integration, cuts the board space needed for these functions by 35 percent.

Figure 3: A 2020 power stage IC combines power devices in a half-bridge topology with drivers, level shifter, bootstrap circuit, input logic and protection.

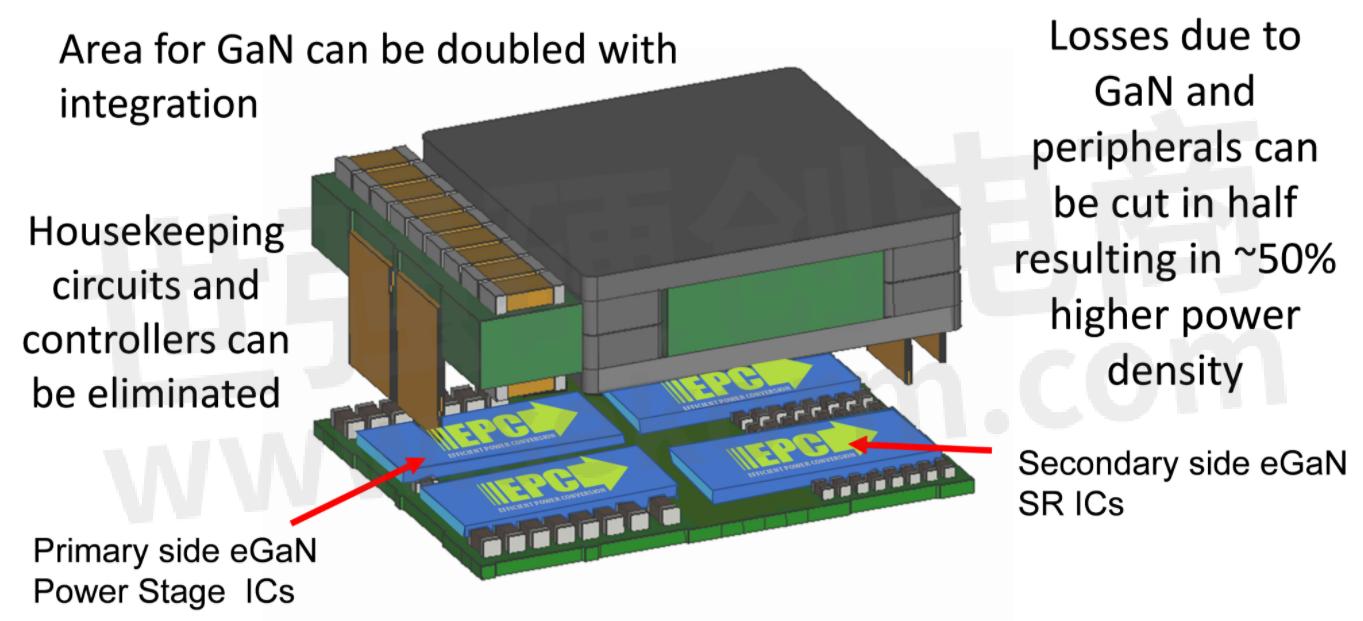

This GaN IC technology can be used to further increase power density by another 50 percent. A conceptual illustration of the improvement resulting from integrated ICs is shown in figure 4.

Figure. 4: The impact on power density from increased integration of GaN-on-Si components

Don't Forget the Fan!

Despite all the improvements in power density and efficiency, power requirements for servers continue to climb. In turn, these increases in power requirements escalate the requirements for cooling systems, and, thus, the power consumption needed for cooling fans and pumps.

Fans can operate more efficiently at 48V than at 12V and can therefore benefit from GaN IC-based motor controls.

In figure 5 is shown a server cooling fan controlled by a 48 VIN brushless DC motor (BLDC) driven by three EPC2152 ICs (shown earlier in figure 3). The same efficiency, size, and cost improvements realized from GaN in server DC-DC converters are realized in the fan motor controls used to power on-board cooling fans.

Figure. 5: The EPC9146 motor control reference design powers a 400W server cooling fan

IC Roadmap

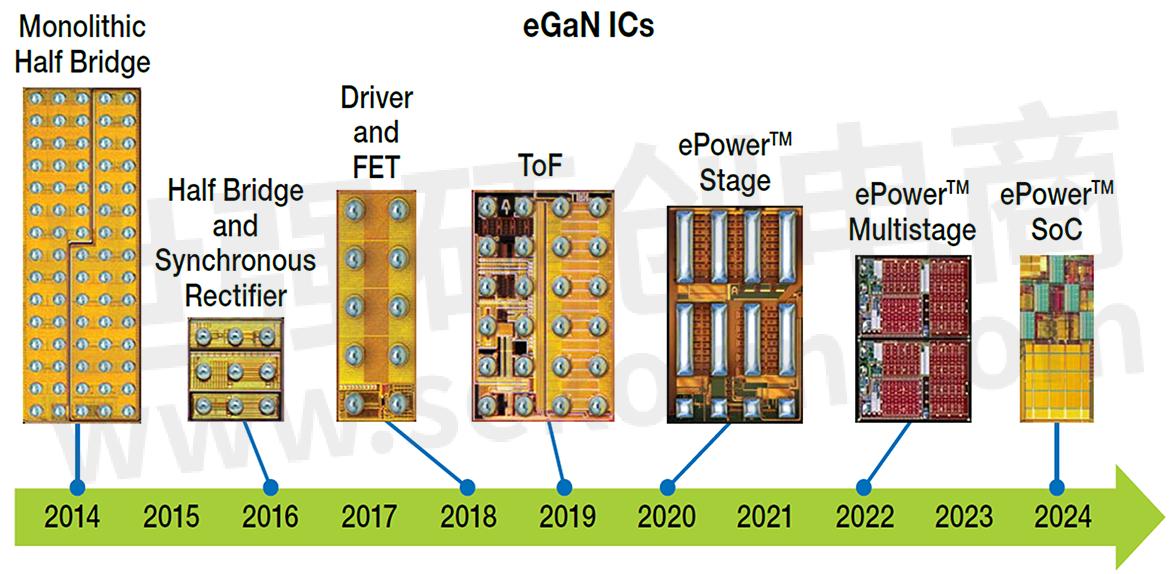

GaN-on-Si integrated circuit technology is in its infancy. Improvements in performance, cost, as well as features and functions, are being introduced almost monthly. Figure 6 shows key topology milestones in GaN integration starting with the first monolithic half-bridge devices introduced in 2014. In 2022, expect multistage ICs, followed by power-plus-control systems on a single chip in 2024.

Figure 6: GaN integration milestones. Multistage ICs will be available in 2021, power-plus-control systems on a single chip in 2024

Summary

The conversion to 48V on the server board has driven GaN-on-Si transistors into high-volume, low-cost production. Prices for GaN transistors are consistently lower than Si MOSFETs. This lower cost, coupled with the higher performance and smaller size, make GaN the compelling choice for 48V DC-DC converters and BLDC motors used in servers.

These same elements of value – higher performance, smaller size, and lower cost – are pulling GaN ICs into 48V DC-DC converters used in automotive applications. As fuel efficiency standards increase, a significant shift is occurring, with electric and mild hybrid vehicles adding 48V batteries and requiring 48 – 12V bi-directional converters. GaN transistors and IC are already populating these new systems and will certainly be the component of choice over time.

- +1 Like

- Add to Favorites

Recommend

- EPC‘s ePower Stage EPC2152 Integrated Circuit Named Finalist in Prestigious Elektra Awards

- EPC2152 Receives Elektra Award 2020 for Semiconductor Product of the Year (Analogue) for ePower Stage IC

- EPC2152 ePower™ Stage – Redefining Power Conversion

- EPC2152 GaN Integrated Power Stage – Redefining Power Conversion

- EPC Revolutionizes Lidar System Design with Release of EPC21601 eToF Laser Driver IC

- EPC21601 eToF Laser Driver IC Wins ASPENCORE’s World Electronics Achievement Award – Product of the Year 2021 Power Semiconductor / Driver IC

- EPC Launches 400 W Motor Drive Demonstration Powered by GaN Integrated Power Stage

- Sharge Selects GaN FETs EPC2218 from EPC for High-power USB PD Charger Retro 67 to Achieve the Most Efficient Power Conversion

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.