Extensive Reliability Tests Prove the Suitability of 3D e.MMC MLC and SLC Mode for Demanding Industrial Automotive Application

Several years ago, only native single-level cell NAND flash (SLC NAND flash) was deemed suitable for industrial and automotive applications requiring high levels of reliability and endurance. Since SLC flash supports two logical states to store just one bit of binary data per cell, it is less prone to bit errors and was therefore the preferred flash storage technology for critical operations facing thermal, shock, vibration, power, and environmental challenges.

As NAND technology advanced, improvements in controller features have enabled multi-level cell flash (MLC flash) to deliver significantly better error correction handling, reliable performance, and extended service life.

With 3D flash technology, advancements continue to be made by leaps and bounds. It enables flash storage media to increase not only in density by scaling vertically, but also mitigates common issues associated with shrinking lithography in planar or 2D NAND, such as cell-to-cell interference.

ATP conducted a series of reliability tests to demonstrate the suitability of MLC mode NAND flash and SLC mode NAND flash in its e.MMC offerings for mission-critical applications while providing ample storage density and stable performance in extreme environments.

The following e.MMC products were included in the reliability tests:

• E600Si/E600Sia (3D MLC) from 16GB to 128GB

• E700Pi/E700Pia (3D SLC mode) from 8GB to 64GB

HIGHLIGHTS

Storage Reliability: Extended Data Retention

Storage reliability tests measured the e.MMC’s ability to retain data without degradation in relation to temperature, P/E cycles, and time period as key factors. Actual test results show that the ATP 3D e.MMC retains data longer than specified in the datasheet.

The following data retention test results graph shows that the ATP 3D e.MMC is very suitable for read-intensive applications that require longer data retention at the same P/E cycle conditions even when stored in harsh environments.

Figure 1. Data retention results comparing market standard and actual test data for ATP 3D MLC e.MMC

SMT Resistance with 3X Reflow at 3D NAND Full Capacity: Data Integrity and Production Efficiency

Reliability tests show that the ATP 3D e.MMC can retain pre-loaded content and maintain data integrity at full capacity during the Pb‑free reflow process.

Similar to the 2D MLC production method, ATP tests the 3D e.MMC with content already loaded prior to soldering, thus eliminating the need to go through the host OS and ensuring that there is no interface bandwidth loss. Bypassing the preload process after SMT assembly ultimately translates to excellent production efficiency.

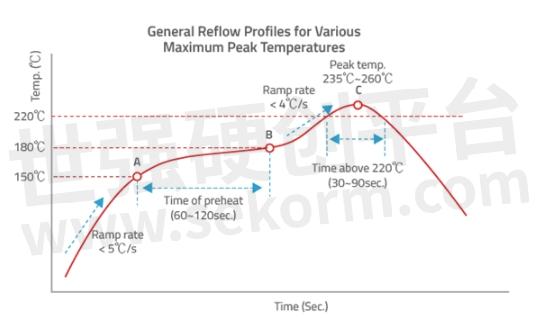

The graph below shows that before being soldered to the board, the e.MMC was subjected to three intense levels of Pb-free reflow temperature, which are higher than Pb (lead) profiles.

Figure 2. General Reflow Profiles for Various Maximum Peak Temperatures. The ATP 3D e.MMC can resist up to three intense levels of Pb-free reflow temperature, which refer to JEDEC-defined reflow profiles. It also delivers excellent production efficiency by being able to keep the production method as 2D MLC e.MMC.

Terabytes Written (TBW): Higher than Benchmark

NAND flash has a finite number of program/erase cycles. One common specification used to measure endurance is TBW, which refers to the total amount of data that can be written onto a storage device before it is bound to fail. A higher TBW means the storage device has a longer usage life.

Based on the tests conducted, the ATP 3D e.MMC has a high TBW, making it suitable for write-intensive applications.

The 3D MLC e.MMC has at least 60% higher TBW than similar products in the market, while the 3D SLC mode (pseudo SLC) e.MMC has at least 5% higher TBW.

Calculation: Sequential Write

Table 1. ATP 3D e.MMC TBW ratings

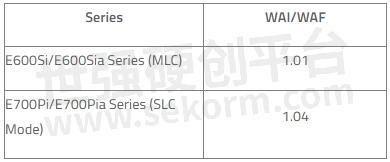

Low Write Amplification Index/Factor (WAI/WAF): Best TCO Value

WAI/WAF refers to the ratio of the total gigabytes written by the host to the NAND. A WAI value of 1 is ideal, as it means that 1 MB of data from the host is written as 1MB NAND flash memory on the flash storage device.

Due to the nature of flash, blocks must first be erased before they can be written to and any valid data on the old block is first copied or relocated to a spare block. In write-intensive operations, this cycle of relocating, rewriting, and erasing can cause data written on the flash storage device to be amplified (it becomes greater than what the host had intended to write). A high WAI/WAF rating increases writes on the drive, therefore reducing its lifespan.

The ATP 3D e.MMC’s low WAI/WAF translates to a longer lifespan, higher endurance, and optimal total cost of ownership (TCO).

Sequential Write Test Results (Linux DD, 0x00)

Table 2. ATP 3D e.MMC WAI/WAF ratings

Conclusion

Based on the results of the reliability tests, the ATP e.MMC with 3D SLC Mode NAND flash and MLC NAND flash deliver reliable performance for industrial and automotive applications requiring high density and long endurance.

- +1 Like

- Add to Favorites

Recommend

- ATP Rapid Diagnostic Test (RDT): Accelerating Failure to Maximize Reliability and Endurance

- News | NAND Flash Storage Solutions for the Data-Driven 5G Era | ATP

- ATP Electronics’ Latest pSLC Embedded SSDs Offer Best TCO with Customizable Endurance

- The ATP Gym and Coach System: Exercising SSDs to Ensure Total Fitness

- ATP‘s PCB Assembly Solderability Validation Tests

- New Die Package Extends 3D TLC e.MMC Endurance to MLC/SLC Levels of ATP E750Pi/Pc, E650Si/Sc Series e.MMC

- How ATP Protects Your Data and SSDs with HW/FW Power-Loss Protection

- SecurStor-enabled ATP Flash Storage Devices Secure Your Data with AES-256 Encryption

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.