The Three Factors that Affect the Performance of the Thermal Silicone Pad During Use

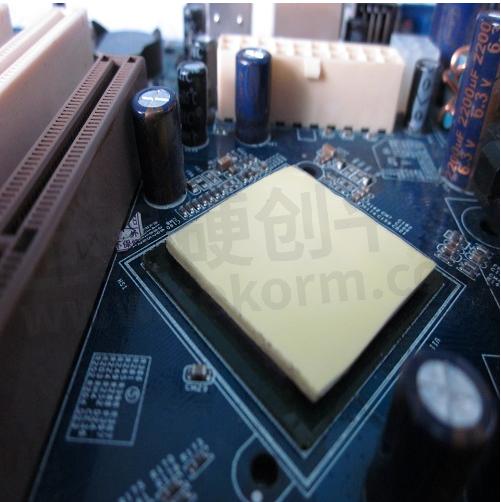

Thermal silicone pad is one of the more commonly used traditional thermal conductive materials. It is a kind of soft silicone as the base material and is made of thermally conductive, temperature-resistant, and insulating materials in a certain proportion. It has high thermal conductivity. , Low thermal resistance, insulation, resistance to cold and thermal shocks, etc., it acts between the heating element and the radiator, fills the gap between the interface and removes the air from the interface, reduces the contact thermal resistance, improves the thermal conductivity, and at the same time can provide insulation, Shock absorption, and sealing.

Some customers will find that the thermal conductivity effect of the Thermal silicone pad is not as expected when using the thermally conductive silicone sheet. What are the factors that will affect the thermally conductive silicone sheet when using the thermally conductive silicone sheet?

First of all, the Thermal silicone pad is used as a medium material that directly contacts the heat source and the radiator. The bonding surface needs to be cleaned before use, and the stains on the surface should be removed as much as possible, so as not to affect the heat transfer efficiency. Just lightly fit on the flat surface.

Then, to completely cover the plane, the thermally conductive silicone sheet is different from thermally conductive paste or thermally conductive gel. It is a solid insulating sheet, which needs to be determined according to the size of the surface before use, unlike thermally conductive gel and thermally conductive paste. The flowing paste can cover the plane under proper pressure, so as to avoid the loss of heat dissipation effect due to insufficient coverage.

Secondly, whether the radiator reaches the expected target value, many people focus on the thermal conductive material but do not notice that the main body of the radiator is the radiator. The Thermal silicone pad is mainly used to reduce the contact thermal resistance and improve the heat transfer efficiency, thereby improving the Heat dissipation effect, and heat dissipation still needs a radiator. If the heat dissipation value of the radiator does not meet the requirements, then the thermal conductivity of the Thermal silicone pad is useless no matter how high.

- +1 Like

- Add to Favorites

Recommend

- Why Does Thermal Resistance Affect the Thermal Conductivity of Thermal Silicone Pad?

- Application of Thermal Silicone Pad in Fast Charging Source Adapter

- How to Choose Thermal Silicone Pad? Sheen Helps You Solve the Selection Problem

- Sheen SF series Thermal Silicone Pad: Heat Dissipation Solution for DC Equipment MOS Shielding Cover

- Thermal Grizzly CPU Contact Frame Intel 1700 LT is Now Available

- Thermal Grizzly Product Update: AM5 High-Performance Heatspreader with New Nickel Plating

- What Are the Factors that Affect the Thermal Conductivity of Thermal Pad?

- The Next Generation of Thermal Gap Filler Pad: THERM-A-GAP PAD 80LO, with a Thermal Conductivity of 8.3 W/m-K

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.