What Are the Factors that Affect the Thermal Conductivity of Thermal Pad?

For most electronic product R & D engineers, understanding the characteristics of various thermal conductive materials is their indispensable homework. Only with sufficient knowledge of the materials, an excellent thermal system can be designed. As the most representative thermal pad in thermal interface materials, it is mainly composed of organic silicone, which has a certain ductility, can well fill the gap between the heating element and the heat sink, exclude air on uneven surfaces, and form good heat flow channels. Therefore, an excellent thermal pad can help electronic products play better performance.

What kind of thermal pad is excellent? Considering which aspects of a thermal pad?

Thermal Conductivity

This is a factor that everyone is most concerned about. Thermal conductivity refers to a 1m thick material with a temperature difference of 1 degree (K, ℃) on the surface of both sides under stable heat transfer conditions. In 1 hour, the heat transferred through an area of 1 square meter is expressed in watts/meter · degree (W / (m · K), where K can be replaced by ℃). The higher the thermal conductivity of the thermal pad, the faster it can conduct the heat of the electronic components to the heat sink, and the better of the thermal conductivity.

Density

The porosity of various thermal insulation materials is usually very high. Relatively, their density is also very low; while the silicone sheet as a thermal conductive material is just the opposite. The larger the porosity, the worse the heat transfer performance of the thermal conductive material.

Hardness selection

When measuring the hardness of thermal conductive materials, Shore hardness is generally used. The test principle is to drop a prescribed diamond punch from a fixed height on the sample surface. The punch bounces a certain height, and the ratio of the bounce height to the drop height is used to calculate the Shore (Shore) hardness.

thermal silicone pad has a lower hardness, a softer feel, and certain ductility, which can better fit the interface gap of components and achieve a more ideal heat flow transmission effect; if the hardness of the thermal pad is too high, the gap cannot be effectively filled. The efficiency of the heat flow will also be reduced.

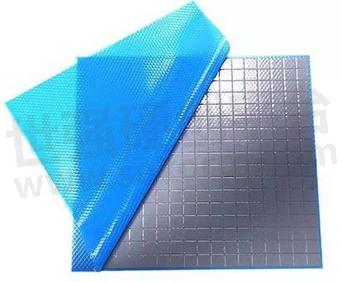

However, the smaller the hardness ≠ the better the thermal conductivity, and if the hardness of the thermal conductive silicone pad is too low, which will cause deformation and tear during the product installation process. In order to avoid this situation, under the premise of meeting the thermal conductivity requirements, Waermtimo will perform a double-sided / single-sided reinforcement treatment on the thermal pad to enhance the toughness of the silicone pad.

Thickness selection

The silicone material has a certain compression resistance, which can effectively reduce the heat flow transmission distance by compressing to enhance the fit of the thermal silicone pad. The selection of the thickness of the silicone sheet depends on the specific components.

Waermtimo has independent research and development, production teams, and factories, providing high-quality thermal conductivity solutions for many international brands.

- +1 Like

- Add to Favorites

Recommend

- Thermal Grizzly CPU Contact Frame Intel 1700 LT is Now Available

- Thermal Grizzly Product Update: AM5 High-Performance Heatspreader with New Nickel Plating

- Does the Thermal Pad Need to Have Glass Fiber?

- Thermal Grizzly Prepared Four New Products for Intel’s Arrow Lake Processors

- Waermtimo Offers High-strength Thermal Conductive Pad and Thermal Pad for High-speed Optical Module Heat Dissipation

- The Next Generation of Thermal Gap Filler Pad: THERM-A-GAP PAD 80LO, with a Thermal Conductivity of 8.3 W/m-K

- Thermal Pad vs Paste: Which is Better for Your Needs?

- Why Does Thermal Resistance Affect the Thermal Conductivity of Thermal Silicone Pad?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.