Why Does Thermal Resistance Affect the Thermal Conductivity of Thermal Silicone Pad?

A common heat dissipation system is composed of a heat source and a radiator, and the heat source and the radiator need to be filled with a thermally conductive material to fill the pits between the gaps and eliminate the air between the gaps to improve the efficiency of heat transfer. There are many kinds of materials, such as thermal silicone pad, thermally conductive paste, thermally conductive phase change film, silicon-free thermally conductive sheet, thermally conductive gel, thermally conductive insulating sheet, carbon fiber thermally conductive gasket, etc., and thermal silicone pad is currently the most used thermally conductive material. First, it has many advantages, which can effectively contact the heat source and the radiator with thermal resistance, so that the heat source and the radiator can be in close contact.

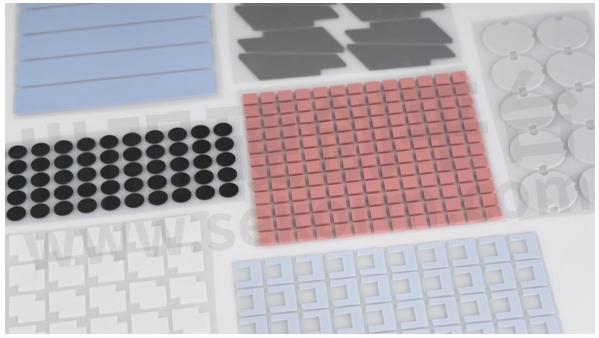

A thermal silicone pad is a kind of gap-filling thermal pad made of silicone resin as the base material and added with temperature-resistant and thermally conductive materials. It has the characteristics of high thermal conductivity, low thermal resistance, insulation, compression, etc. The soft hardness makes it possible to realize a small thermal resistance under low-pressure conditions, and at the same time eliminates the air between the contact surfaces and fully fills the rough surface between the contact surfaces, improving the heat conduction effect of the contact surfaces. Because of the good filling effect of the thermally conductive silicone sheet, it can effectively conduct the heat of the heat source to the shell, and the thermal silicone pad has good compressibility and elasticity, and can serve as a shock-absorbing pad.

Thermal conductivity is a parameter that measures the thermal conductivity of a material, and it is also a parameter that customers pay attention to. In addition to thermal conductivity, thermal resistance also affects the thermal conductivity of thermal silicone pads. There is a saying in the industry: purchase depends on thermal conductivity, and engineering depends on thermal resistance. How does the thermal resistance affect the performance of the thermal silicone pad?

Simply put, the thermal conductivity can be regarded as the size of the water pipe. The larger the thermal conductivity, the thicker the pipe, the more water can flow through, and the thermal resistance is the scale in the water pipe. The greater the thermal resistance, the more scale. The water flow will slow down, which also means that the heat transfer efficiency is reduced. That's why it is said that in addition to the thermal resistance, the other parameters of the thermal silica gel are the same. The smaller the thermal resistance, the better the thermal conductivity.

- +1 Like

- Add to Favorites

Recommend

- Application of Thermal Silicone Pad in Fast Charging Source Adapter

- The Three Factors that Affect the Performance of the Thermal Silicone Pad During Use

- How to Choose Thermal Silicone Pad? Sheen Helps You Solve the Selection Problem

- Sheen SF series Thermal Silicone Pad: Heat Dissipation Solution for DC Equipment MOS Shielding Cover

- Thermal Grizzly CPU Contact Frame Intel 1700 LT is Now Available

- Thermal Grizzly Product Update: AM5 High-Performance Heatspreader with New Nickel Plating

- What Are the Factors that Affect the Thermal Conductivity of Thermal Pad?

- The Next Generation of Thermal Gap Filler Pad: THERM-A-GAP PAD 80LO, with a Thermal Conductivity of 8.3 W/m-K

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.