Pinpoint Precision: Harnessing the Power of Board-to-Board Pin Headers

In the realm of electronic connections, precision is paramount. Every millimeter can make a difference in performance, reliability, and overall functionality. One unsung hero that plays a crucial role in achieving such precision is the Board-to-Board Pin Header. Though often overlooked, these small components are the backbone of modern electronics, facilitating seamless connections between printed circuit boards (PCBs) and enabling devices to function at their best. In this blog, GREENCONN will delve into the world of Board-to-Board Pin Headers, exploring their design, applications, and the remarkable advantages they bring to the electronics industry.

What Are Board-to-Board Pin Headers?

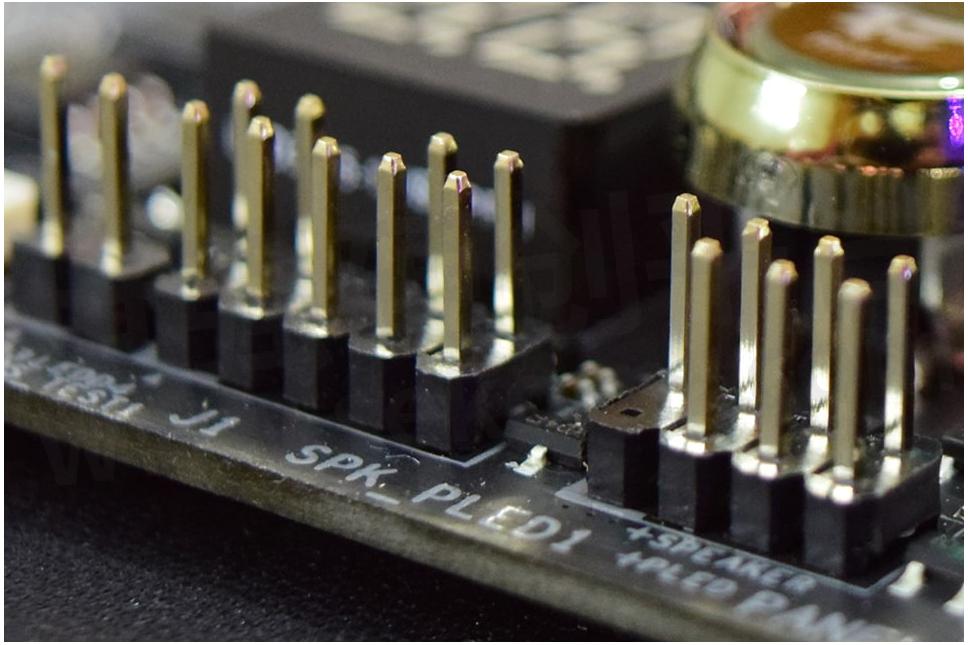

Board-to-Board Pin Headers, also known as PCB connectors or pin headers, are small, slender components designed to connect two or more PCBs together. They consist of a series of pins or terminals arranged in a precise grid pattern, allowing for accurate alignment and secure attachment. The pins are typically designed to be soldered onto the PCBs, ensuring a reliable and permanent connection.

The Precision Design

One of the most significant advantages of Board-to-Board Pin Headers lies in their precision design. Manufacturers meticulously engineer these connectors to provide consistent spacing between the pins, allowing for exact alignment between the connected PCBs. This precision ensures that electrical signals can flow seamlessly between the boards, minimizing signal loss and crosstalk.

Furthermore, Board-to-Board Pin Headers are available in various pitch sizes, such as 0.1 inches (2.54 mm), catering to different electronic applications. The option to choose the right pitch enables designers to achieve the desired level of connectivity and compactness in their electronic devices.

Versatility in Applications

The applications of Board-to-Board Pin Headers are diverse and widespread across various industries. From consumer electronics like smartphones and laptops to industrial equipment and automotive systems, these connectors are at the heart of countless electronic devices.

In addition to standard board-to-board connections, pin headers are also used in conjunction with other connectors, such as ribbon cables and wire-to-board connectors, expanding their versatility. This adaptability makes them indispensable in scenarios where different types of connections are required within the same device.

Ease of Assembly and Repair

Board-to-Board Pin Headers are designed with ease of assembly and repair in mind. Their standardized grid pattern and well-defined orientation make it straightforward to attach and align the connectors during manufacturing. Additionally, they are often designed for through-hole soldering, which simplifies the assembly process even further.

Furthermore, if a PCB component needs replacement or repair, desoldering and replacing the pin header is relatively easy. This characteristic enhances the longevity of electronic devices, as individual components can be serviced or upgraded without replacing the entire board.

In conclusion, Board-to-Board Pin Headers may seem unassuming, but they are the unsung heroes that enable the seamless connectivity and precision required in modern electronics. Their precision design, versatility, and ease of assembly make them essential components in a wide range of electronic applications.

- +1 Like

- Add to Favorites

Recommend

- Small but Mighty: The Impact of Board-to-Board Pin Headers on Electronic Design

- What Are the Different Types of Board-to-Board Connector Box Headers?

- Classification and Characteristics of Board-to-Board Connectors

- ept One27® SMT PCB Connectors with a Pitch of 1.27mm is Suitable for Board-to-board Applications ∣ video

- How to Select Board-to-board Connectors?

- Basic Performance of Board-to-Board Connectors

- Application Areas of Board-to-Board Connector Terminals

- What Should Be Noted When Testing Board-to-Board Power Connectors?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.