What Are the Different Types of Board-to-Board Connector Box Headers?

When it comes to electronic connections, board-to-board connectors play a crucial role in ensuring seamless communication between circuit boards. Among the various types of board-to-board connectors, box headers are particularly popular for their versatility and reliability. In this article, GREENCONN will delve into the world of Board-to-Board Connector Box Headers. From understanding their significance to exploring the different types available, this comprehensive guide will provide you with valuable insights to help you make informed decisions for your electronic projects.

Understanding the Significance of Board-to-Board Connector Box Headers

Board-to-board connector box headers serve as interface connectors between two or more circuit boards. They establish electrical connections, allowing for the transfer of signals, power, and data between the connected boards. These headers are vital in applications where multiple boards need to be interconnected within an enclosure or device.

Exploring the Various Types of Board-to-Board Connector Box Headers

Dual Row Box Headers:

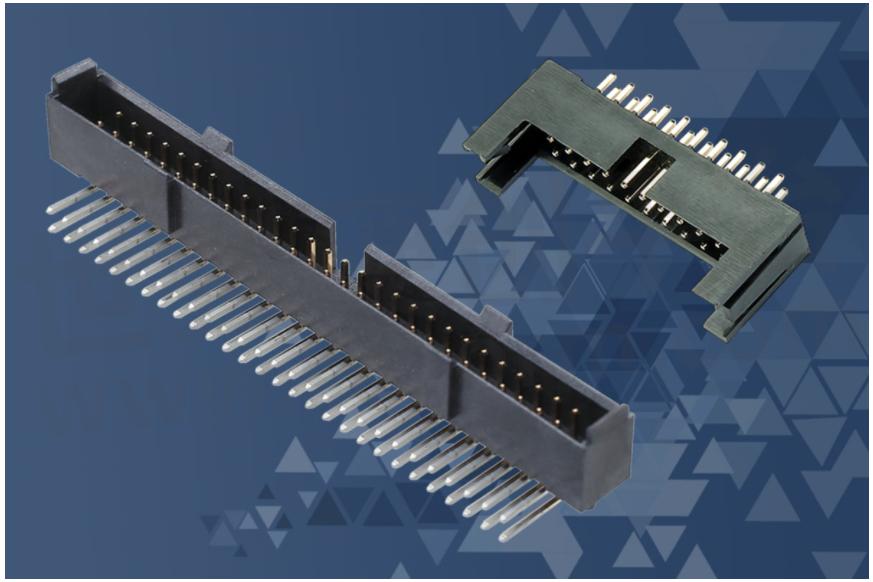

Dual row box headers are one of the most common types of board-to-board connectors. As the name suggests, they consist of two rows of pins on each side, providing a higher pin density for connections. Dual row box headers are often used in applications where a larger number of connections are required between the boards. They offer increased versatility and enable reliable data transfer between the connected circuit boards.

Single Row Box Headers:

Single row box headers are another popular type of board-to-board connectors. They feature a single row of pins on each side, allowing for a more compact and space-efficient connection between the boards. Single row box headers are suitable for applications with limited board space or where fewer connections are needed. They provide a reliable and straightforward solution for connecting circuit boards within an enclosure.

Shrouded Box Headers:

Shrouded box headers offer additional protection and stability to the connected boards. They feature a plastic shroud that covers the pins, providing insulation and shielding from external elements. The shroud also acts as a guide, ensuring proper alignment and preventing accidental misconnections. Shrouded box headers are commonly used in applications where there is a need for extra security, such as in industrial environments or high-vibration settings.

Right-Angle Box Headers:

Right-angle box headers are designed to allow connections at a 90-degree angle. This type of connector is useful when space constraints or specific board orientations make straight connections challenging. Right-angle box headers enable efficient and compact connections in situations where boards need to be positioned perpendicular to each other within an enclosure or device. They offer flexibility in design and facilitate optimal use of available space.

SMT (Surface Mount Technology) Box Headers:

SMT Box Headers are specifically designed for surface mount applications. Instead of through-hole mounting, where the pins pass through the board, SMT box headers have surface-mountable pads on the underside, allowing for direct attachment to the surface of the circuit board. This type of connector is widely used in modern electronics manufacturing, as it offers precise and automated assembly processes, reducing manufacturing time and costs.

High-Density Box Headers:

High-density box headers are engineered to provide a higher pin density within a limited space. These connectors feature closely spaced pins that enable a larger number of connections in a compact form factor. High-density box headers are ideal for applications where space is a premium, such as in portable electronic devices or densely populated PCBs. They allow for efficient board-to-board connections without sacrificing functionality.

- +1 Like

- Add to Favorites

Recommend

- Everything You Need to Know About PCB to Box Headers

- LC Duplex Fiber Optic Connectors for High Density Environments with the Features of High-reliability, Low-cost And High-density

- What is the HDI (High-Density Interconnect) Printed Circuit Boards?

- Revolutionizing Medical Devices with Smiths Interconnect High-Density Connectors D04

- Smiths Interconnect enhances performance of its High-Density Signal PCB Connector HPH Series

- Kinghelm KH-2.54PH180-2X8P-L8.9 IDC Connector:The Future of High-Density Connections

- Kinghelm KH-2.54PH180-3X40P-L11.5 Pin Header Connector: High-Density Data Transmission Ideal Choice

- TE Connectivity Extends Heavy Duty Connector Range with high-density Compact Unit suited for Robotics and Automation Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.