Everything You Need to Know About PCB to Box Headers

In the world of electronics, making the right connections is vital for seamless operation and functionality. When it comes to connecting printed circuit boards (PCBs) to external devices or enclosures, PCB to Box Headers play a crucial role. In this article, GREENCONN will explore everything you need to know about PCB to box headers. From understanding their significance to providing practical tips on their effective usage, this comprehensive guide will help you harness the full potential of PCB to box headers in your electronic projects.

Understanding the Role of PCB to Box Headers:

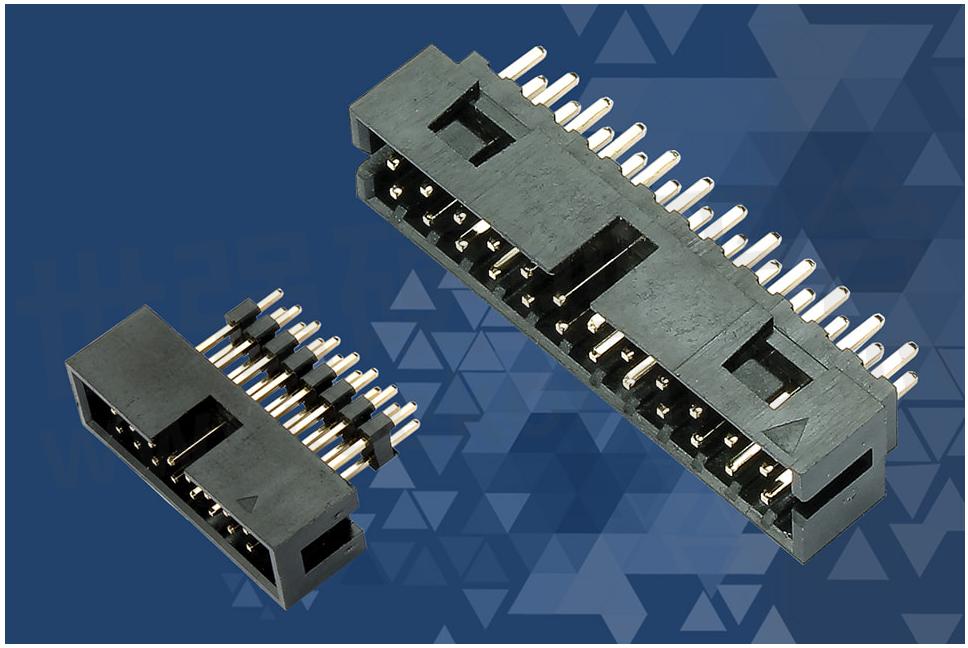

PCB to box headers are connectors that facilitate the secure and reliable connection between a PCB and an external device or enclosure. These headers typically consist of male and female connectors, allowing for easy and efficient connections. They are commonly used in applications where PCBs need to be mounted inside a box or enclosure while maintaining accessibility for external connections.

A Comprehensive Guide to Utilizing PCB to Box Headers Effectively:

Compatibility and Pin Configuration:

When selecting PCB to box headers, ensure compatibility between the connectors and the devices or enclosures you are working with. Consider the pin configuration of the headers, including the number of pins, their spacing, and alignment. Verify that the pin configuration matches the requirements of both the PCB and the external device or enclosure for seamless integration.

Mounting Options:

PCB to box headers come in different mounting options, such as through-hole or surface mount. Choose the appropriate mounting option based on your specific project requirements and the available space inside the box or enclosure. Consider factors like accessibility, ease of assembly, and the overall mechanical stability required for a robust connection.

Secure Connections:

To ensure reliable connections, it is crucial to properly secure the PCB to box headers. Utilize appropriate hardware, such as screws or bolts, to fasten the headers firmly to the enclosure or device. This ensures that the connections remain stable, even in challenging environmental conditions or situations that involve vibrations or movement.

Consider Environmental Factors:

When selecting PCB to box headers, take into account the environmental factors that the connectors may encounter. If your project involves outdoor applications or exposure to moisture, dust, or temperature extremes, opt for headers with appropriate sealing or shielding features. These features enhance the connectors' resistance to external elements and help maintain reliable connections over time.

Customization and Flexibility:

PCB to box headers often allow for customization and flexibility in terms of pin lengths, keying options, and additional features. Consider these options based on your specific project needs. Customization can include different pin lengths to accommodate varying depths inside the enclosure or the inclusion of keying features to prevent improper connections. Ensure that the headers' design and customization options align with your project requirements.

Cable Management:

Efficient cable management is crucial when using PCB to box headers. Properly organize and route the cables within the enclosure to minimize strain on the connectors and ensure a clean and organized setup. Consider using cable ties, clamps, or cable management accessories to secure and route the cables neatly, reducing the risk of cable damage or disconnections.

Testing and Maintenance Considerations:

During the development and maintenance phases of your project, it is essential to have easy access to the PCB to box headers for testing or troubleshooting purposes. Design the layout and placement of the headers with accessibility in mind, allowing for easy connections and disconnections when necessary. This facilitates efficient testing, debugging, and future modifications if required.

PCB to box headers play a significant role in connecting PCBs to external devices or enclosures, enabling seamless integration and functionality. By understanding their role and following the practical tips provided in this guide, you can effectively utilize PCB to box headers in your electronic projects.

- +1 Like

- Add to Favorites

Recommend

- Four Points to Control the PCB Cost: PCB Layers, PCB Dimensions, Manufacturing Difficulty and PCB Sheet Material

- What Are the Different Types of Board-to-Board Connector Box Headers?

- ATP‘s PCB Assembly Solderability Validation Tests

- Digging Deeper into Dielectric Constant for PCB Materials

- What You Need to Know About PCB Card Edge Connectors

- Right Mix of Materials and Fabrication Brings Consistent PCB Dk and Phase

- Pinpoint Precision: Harnessing the Power of Board-to-Board Pin Headers

- Greenconn荣获邓白氏企业认证,实力彰显行业领先水平

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.