What You Need to Know About PCB Card Edge Connectors

In the world of electronics, PCB Card Edge Connectors (Printed Circuit Board card edge connectors) play a crucial role in establishing reliable and secure connections between PCBs and external devices. Whether you're working on a computer, a gaming console, or any other electronic device, understanding the significance of PCB card edge connectors is essential. In this article, GREENCONN will explore the fundamentals of PCB card edge connectors, their importance, and the key features you should consider when choosing the right connectors for your projects.

Understanding the Significance of PCB Card Edge Connectors:

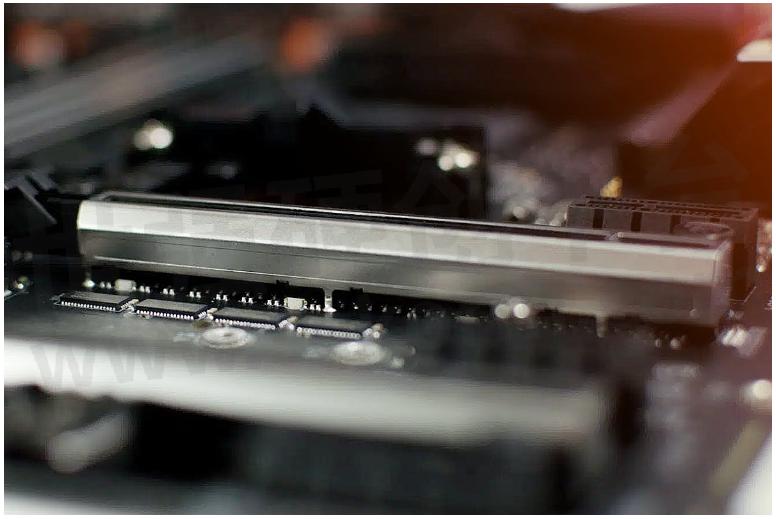

PCB card edge connectors serve as the interface between a PCB and an external device, providing a reliable electrical connection for power, data, and signals. They are specifically designed to mate with the edge of a PCB, making them ideal for applications where repeated insertions and removals are required. These connectors are commonly found in computers, telecommunication equipment, industrial machinery, and various other electronic devices.

Key Features and Considerations for Choosing PCB Card Edge Connectors:

Connector Type and Form Factor:

PCB card edge connectors come in various types and form factors, such as single-row, double-row, and multi-row configurations. Consider the specific requirements of your project and choose a connector type that matches your needs. Single-row connectors are suitable for applications where space is limited, while double-row or multi-row connectors provide higher pin densities for increased functionality.

Contact Material and Plating:

The choice of contact material and plating is crucial for ensuring reliable and low-resistance connections. Common contact materials include phosphor bronze and beryllium copper. Look for connectors with gold, tin, or silver plating, as these materials offer excellent conductivity, corrosion resistance, and durability. The plating also helps prevent oxidation and promotes a long lifespan for the connectors.

Insertion and Extraction Forces:

Consider the insertion and extraction forces required for the connectors. Connectors with appropriate insertion and extraction forces ensure a secure yet easy-to-use connection. You want to avoid connectors that are too loose, as they may result in intermittent connections, or connectors that are too tight, as they may make insertion and removal difficult or damage the PCB.

Signal Integrity and High-Speed Applications:

For applications involving high-speed data transmission, it is essential to choose PCB card edge connectors that offer excellent signal integrity. Look for connectors with impedance-matched designs and proper shielding to minimize signal loss, crosstalk, and electromagnetic interference (EMI). These features are crucial for maintaining signal integrity in high-speed applications such as data centers or communication systems.

Environmental Considerations:

Evaluate the environmental conditions in which your electronic system will operate. If your project involves exposure to moisture, dust, or extreme temperatures, consider choosing connectors with appropriate sealing or protective features. Connectors with gaskets, shrouds, or ruggedized designs can help protect against environmental factors and ensure reliable performance even in challenging conditions.

Durability and Lifecycle:

Consider the durability and lifecycle of the connectors, especially if your application requires frequent insertions and removals. Look for connectors that are designed for high mating cycles, ensuring long-lasting performance and reduced maintenance requirements. Connectors with reinforced contact pins or robust housing materials can withstand the rigors of frequent usage, making them ideal for applications that demand reliability and durability.

Compliance and Standards:

When selecting PCB card edge connectors, ensure that they comply with industry standards and regulations. Look for connectors that meet or exceed specifications such as IPC standards or RoHS compliance. Compliance with these standards ensures that the connectors are manufactured to high-quality standards and are suitable for use in a wide range of applications.

PCB card edge connectors are vital components for establishing reliable and secure connections between PCBs and external devices. Making the right choice will contribute to the overall performance, reliability, and longevity of your electronic systems.

- +1 Like

- Add to Favorites

Recommend

- What Is a PCB Card Edge Connector?

- Why Is Card Edge Connector Called “Goldfinger“?

- SMART Modular Technologies Expands DuraMemory Portfolio with New DDR5 Very Low Profile ECC UDIMMs

- Coherent Demonstrated Next-generation Transceiver Technology for Digital Coherent Optics in Ultracompact Pluggable form Factors for Disaggregated Systems at ECOC 2023

- TE Connectivity Debuts Next-generation Server Sockets and Connectors to Support Advanced Data Center and Edge Computing Applications

- ATP “Industrial Only” Memory Cards: Gateways to the Intelligent Edge in the Smart Factory

- ept 1.27mm-Pitch Straight One27® SMT PCB Connectors Available with Short Delivery Time

- Greenconn荣获邓白氏企业认证,实力彰显行业领先水平

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.