Nippon Chemi-Con Increased Production of Low- Resistance Electric Double Layer Capacitors DLCAP™ for Passenger Vehicles

Nippon Chemi-Con Corporation increased production of low-resistance Electric Double Layer Capacitors (EDLC), DLCAP™, developed for use in vehicles such as capturing kinetic energy and storing as electricity in regenerative braking energy systems.

First adopted by Mazda Motor Corporation (Mazda) last year, low-resistance EDLC has been adopted by another automaker this summer. Nippon Chemi-Con expected sales of "DLCAP™" for this fiscal year to be 4 billion yen, about a tenfold increase compared to two years ago when the supply to automakers was yet to start.

The EDLC for use in vehicles, developed with Nippon Chemi-Con's unique technology, features significantly reduced internal resistance. To lower internal resistance, methyl cyanide (acetonitrile) is commonly used as a solvent for electrolytes; however, acetonitrile is highly toxic and is designated as a poisonous substance under Japanese law.

As environmental regulations are expected to be further strengthened in most countries, Nippon Chemi-Con uses the very safe "propylene carbonate", not acetonitrile, with the view to long-term use of EDLC. Through extensive structural design research, Nippon Chemi-Con developed the EDLC, using the very safe propylene carbonate, which features less than half of the internal resistance compared to the previous series.

Nippon Chemi-Con's newest product (EDLC) also has a broader operating temperature range, from -40 to +70 degrees Celsius (from -25 to +60 degrees Celsius for the previous series), allowing them to be ideally suited for use in automotive applications. Superior heat resistance allows them to be placed within the engine compartment and improved low-temperature properties allow them to deliver high performance in cold climates.

After being adopted by Mazda, Nippon Chemi-Con has extended the product line of low-resistance EDLC for automotive use. The product line has become a standard series that Nippon Chemi-Con named "DXE" and started being supplied to a new-model vehicle launched by another automaker this September.

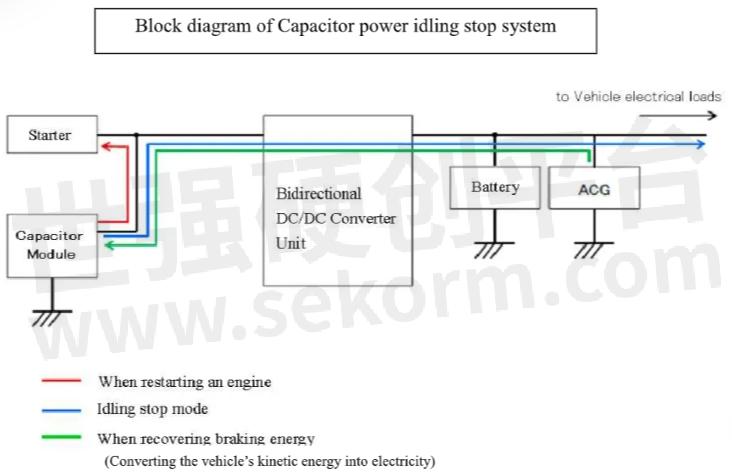

This new-model vehicle features an idling stop system which improves fuel economy and a regenerative braking energy system in which EDLC has been adopted to store electricity. When the vehicle decelerates, electricity generated by the alternator is transferred to the EDLC for storage. By distributing the electricity stored in EDLC to the vehicle's electrical components when the vehicle is in the idling stop mode, the system reduces the need for the engine to burn extra fuel to generate electricity, thereby improving fuel economy.

The electricity to start an engine was supplied by EDLC. This was the first time in the world that a system to start an engine only using electricity stored in EDLC has been adopted in a mass-produced vehicle. By using EDLC instead of a lead-acid battery for frequent engine starting, the load on the vehicles lead-acid battery is expected to be reduced, and the life span of the battery is expected to be prolonged.

EDLC for use in vehicles have been produced at Chemi-Con Yamagata Corporation (Nagai City, Yamagata Prefecture, Japan: 100% owned subsidiary of Nippon Chemi-Con) and EDLC modules have been assembled at Chemi-Con Nagaoka Corporation (Nagaoka City, Niigata Prefecture, Japan: 100% owned subsidiary of Nippon Chemi-Con).

By also strengthening sales to existing markets such as industrial machinery and UPS (Uninterruptable Power Supply), Nippon Chemi-Con intended to achieve the DLCAP™ sales goal of 4 billion yen for this fiscal year. Demand for EDLC increased in industrial equipment and renewable energy markets as well. Nippon Chemi-Con aimed to boost sales of DLCAP™ to 10 billion yen by the end of fiscal year 2015.

EDLC for Use in Vehicles DXE Series

EDLC Cell and Module

- +1 Like

- Add to Favorites

Recommend

- Nippon Chemi-Con to Supply Electric Double Layer Capacitors DLCAP™ for Passenger Vehicles

- Nippon Chemi-Con Developed Supercapacitor DLCAP™ Modules MDKA150S8R3PE6111A for Industrial Equipment Developed

- Nippon Chemi-Con Added PMA Series Resin-Molded Chip Type Conductive Polymer Aluminum Solid Capacitors With a Low Profile of 3.0mm

- NIPPON CHEMI-CON Signs an Authorized Distributor Agreement with Sekorm

- Nippon Chemi-Con Expanded Product Line of Multilayer Ceramic Capacitors Improving Capacitance Density and with Higher Voltage Resistance

- Nippon Chemi-Con Added SMD Type Conductive Polymer Aluminum Solid Capacitors PXN Series with A Moisture Resistance of 1000 Hours at 85℃ 85% RH

- Nippon Chemi-Con Expanded SMD Type Conductive Polymer Aluminum Solid Capacitors PXT Series Guaranteeing 1000 Hours at 85℃ 85%RH

- Nippon Chemi-Con GOB, MXB and HSF Sereis Aluminum Electrolytic Capacitors with an Upper Category Temperature of 150℃

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.