Advantages for industrial process analysis (PAT) with the new ultra-high-temperature jacket (UHTJ)

The new ultra-high-temperature jacket (UHTJ) offers additional protection for fibers coated with polyimide (PI), silicone and high-temperature acrylate.

fiber optic cables are used in many industrial applications, such as for analysis work. This includes industrial spectroscopy applications in the key sectors of chemicals and pharmaceuticals in particular, as well as pyrometric measurements in steel production. Particularly demanding types of application are those that not only take place in a typically harsh industrial environment but also require protection from high ambient temperatures – such as process analysis applications in industrial spectroscopy. Compared with fibers only coated with polyimide and without a protective jacket, our ultra-high-temperature jacket (UHTJ) offers much-improved abrasion resistance plus excellent mechanical properties for laying, and is very easy to strip during assembly.

The use of process analysis is now an established method for the monitoring and quality assurance of process steps in the chemicals industry, pharmaceuticals, the food industry, and agriculture.

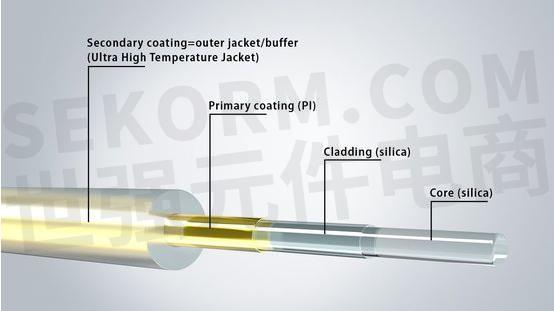

When optical fibers are used for high-temperature applications, the fused silica used to transmit the light in the cable is unproblematic, since it melts at temperatures over 1,000 °C. The fiber coating around the glass material – known as the “jacket” or “buffer” – is more of a problem, however.

One potential high-temperature solution in applications with temperatures up to 700°C is the use of a metal coating like aluminum or gold. These fibers are very expensive, however, and are considered only for exceptional cases where their use is unavoidable. One example is a situation where optical spectroscopy probes have to be dipped into aggressive, hot solutions for taking measurements in the chemicals industry. Much more common, however, is the use of polyimide-coated fibers, which offer a wide temperature range from −190 °C to +385 °C. We are one of the leading manufacturers of these special fibers, which are sold both as plain fiber and as pre-assembled all-in-one solutions.

List of application temperatures:

−40 °C to +150 °C –> High-temperature acrylate jacket

−40 °C to +180 °C -> Silicone jacket

−40 °C to +150 °C -> ETFE jacket

−100 °C to +260 °C -> ultra high-temperature jacket (UHTJ)

−190 °C to +385 °C -> Polyimide without a protective jacket

−269 °C to +400 °C -> Aluminum coating

−269 °C to +700 °C -> Gold coating

While the wide temperature range offered by polyimide-coated fibers is adequate for many high-temperature applications, these fibers do have some disadvantages: they are very sensitive to any mechanical damage to the surface and even small scratches can lead to the fiber breaking. This is not critical for short assembled lengths of up to around a meter. For longer lengths, however, it does become relevant – especially in applications where fibers are moved mechanically.

With its ultra high-temperature jacket (UHTJ), LEONI has developed a mechanically rugged product that offers an industry-optimized solution for many applications, even though its −100 °C to +260 °C temperature range does not quite match that for polyimide. The fiber structure features a polyimide-coated fused silica fiber, onto which a specially designed ultra-high-temperature jacket (UHTJ) is applied using an extrusion process. The jacket offers outstanding chemical stability and is also flame-retarding. The material does not outgas, which means it can be deployed like polyimide in vacuum plants.

Protective ultra high-temperature jacket for fibers coated with polyimide (PI), silicone and high-temperature acrylate

Our customers in industrial spectroscopy have been highly impressed with the benefits of this solution, where its excellent mechanical properties have noticeably reduced the likelihood of plant downtime. This has been the case especially for cable movements – such as when replacing measuring sensors, converting chemical plants, and during scheduled maintenance activities. The often considerable costs related to these earlier problems have also been reduced, since downtime costs also have to be added to the expense involved in spare part procurement.

In industrial environments, we can now offer you an all-in-one solution for optical fiber systems. In the immediate vicinity of the process, fibers with ultra high-temperature jackets (UHTJs) are deployed, which are installed into the respective process sensors or their connections. These are then coupled to optical cables for industrial spectroscopy with extra protection for the less excessive temperatures in the installation area. While high temperatures do not affect these long lengths of fiber, other parameters then become important, such as being easy to lay, ruggedness, UV resistance, and – in particular – compatibility with use in potentially explosive atmospheres (ATEX).

Applications of high-temperature optical fibers are e.g. laser cutting and laser welding plants

Nor is the new jacket material limited to being used to cover a polyimide coating: it can also be extruded onto other jacket materials such as silicone and high-temperature acrylate. Relevant applications for high-temperature optical fibers include laser cutting and laser welding plants, for example, where optical power of several kilowatts is transmitted through a fiber optic cable from a laser unit to an industrial robot. For these cable systems, special pluggable fiber systems are used, which require the removal of coating and jacket during assembly. This is very easy to do with the ultra high-temperature Jacket (UHTJ) material, since it has been designed to be simple to strip.

- +1 Like

- Add to Favorites

Recommend

- Protective ultra high-temperature jacket for polyimide (PI) coated fibers with applications in the extended temperature range of −100 °C to +260 °C

- Rosenberger Released Norma Plus UHD (Ultra High Density) Modular Fiber Panel System

- Ultra-low profile and Ultra-large current Co-fired power inductor-HTF series with an Ultra-low Loss and Ultra-large Current

- Ultra High Power Density Synchronous Full Switching Mode Converter with a Fixed LDO Output, Supporting 4.5V~22V Input Voltage Range

- 3PEAK Unveils TPL8033, a Next-generation Linear Regulator Featuring Ultra-low Noise and Ultra-high PSRR

- Nisshinbo‘s A dual audio operational amplifier NJM8830 featuring ultra-low distortion and ultra-low noise will start producing

- SUL62029——300mA Ultra Low Noise, Low Dropout, High PSRR LDO for RF Analog Circuits with Ultra-Thin Package

- LEONI Offers Cables to Keep North America‘s Military and Law Enforcement in Constant Contact

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.