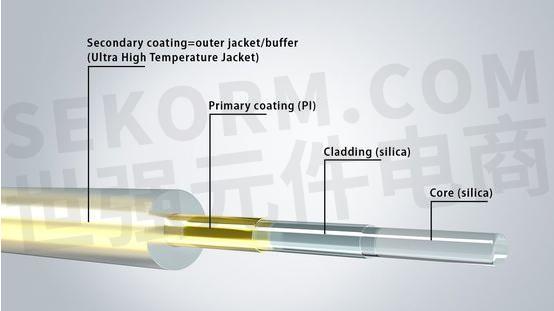

Protective ultra high-temperature jacket for polyimide (PI) coated fibers with applications in the extended temperature range of −100 °C to +260 °C

Compared with fibers only coated with polyimide and without a protective jacket, our ultra high-temperature jacket (UHTJ) offers much-improved abrasion resistance plus excellent mechanical properties for laying, and is very easy to strip during assembly. UHTJ covers a much larger temperature range than fibers with conventional ETFE or PFA jacket coatings, while also offering outstanding resistance to chemical degradation. Depending on the fiber dimension, the UHTJ is available in lengths of up to several kilometers.

For applications involving extremes of temperature, the materials used limit the temperature range at which optical fibers can be used. While polyimide-coated fibers offer a very wide temperature range of −190 °C to +385 °C, these fibers are sensitive and break easily, so are typically assembled only in short lengths of up to about a meter. This is especially true for applications that involve the fibers being moved about mechanically.

While adding protective jacket materials makes the fiber much less likely to break, this once again has an effect on the usable temperature range. Polymer jackets (ETFE) are typical low-cost protective coatings, which can be used at temperatures from −40 °C to +150 °C. This severely restricts the actual temperature range offered by polyimide-coated fibers, however, since the sub-ranges of −100 °C to −40 °C and +150 °C to +385 °C are not covered and cannot be used.

List of application temperatures:

−40 °C to +150 °C –> High-temperature acrylate jacket

−40 °C to +180 °C -> Silicone jacket

−40 °C to +150 °C -> ETFE jacket

−100 °C to +260 °C -> Ultra high-temperature jacket (UHTJ)

−190 °C to +385 °C -> Polyimide without a protective jacket

−269 °C to +400 °C -> Aluminum coating

−269 °C to +700 °C -> Gold coating

Compared with alternative materials, an ultra high-temperature jacket (UHTJ) offers a much broader temperature range of −100 °C to +260 °C. While commercially available PFA jackets based on elastic polymers are usable across a similar temperature range, they are unable to meet key contemporary user requirements such as cost-effective cable stripping. Wider temperature ranges than the range offered by PI-coated fibers are possible only by using expensive metal coatings.

There are many fields of use for fibers and optical cables in the extended temperature range offered by the ultra high-temperature jacket of −100 °C to +260 °C. These include spectroscopy, Fiber Bragg Grating sensors, and process analysis. Monitoring systems for areas exposed to extreme temperatures are also needed in a number of markets, including manufacturing, energy (oil and gas), aerospace, and automotive.

The ultra high-temperature jacket can be combined with a wide range of existing fiber designs. Itsadvantages are best exploited in combination with polyimide-coated fibers – including fiber bundles. In addition, UHTJ also offers a non-conductive surface that is well-suited to use in EMC applications. Since the material does not outgas, it is also suitable for applications in a vacuum. The ultra high-temperature jacket is easily strippable with a modest amount of force and has flawless edges. This makes fibers very easy to process. Within the specified temperature range, UHTJ is a low-cost alternative to metal coatings and can replace existing fibers.

Please talk to us about options for custom cables combined with the new ultra high-temperature jacket – we will be happy to work with you on a solution tailored to your application.

Benefits of the ultra high-temperature jacket (UHTJ) at a glance:

Excellent mechanical properties

Very low coefficient of friction

Excellent strippability

Outstanding resistance to chemical degradation

Self-extinguishing, flame retardant

Non-conductive surface (EMC)

Low-cost alternative to metal coatings (aluminum, gold)

Ordering options:

Fiber type

Ultra high-temperature jacket color

Choice of assembly as cable or fiber bundle

Fields of use:

Spectroscopy

FBG sensors

Process analysis

Manufacturing

Energy (oil and gas)

Aerospace

Automotive

- +1 Like

- Add to Favorites

Recommend

- Advantages for industrial process analysis (PAT) with the new ultra-high-temperature jacket (UHTJ)

- Rosenberger Released Norma Plus UHD (Ultra High Density) Modular Fiber Panel System

- Ultra-low profile and Ultra-large current Co-fired power inductor-HTF series with an Ultra-low Loss and Ultra-large Current

- Ultra High Power Density Synchronous Full Switching Mode Converter with a Fixed LDO Output, Supporting 4.5V~22V Input Voltage Range

- 3PEAK Unveils TPL8033, a Next-generation Linear Regulator Featuring Ultra-low Noise and Ultra-high PSRR

- Nisshinbo‘s A dual audio operational amplifier NJM8830 featuring ultra-low distortion and ultra-low noise will start producing

- SUL62029——300mA Ultra Low Noise, Low Dropout, High PSRR LDO for RF Analog Circuits with Ultra-Thin Package

- LEONI Offers Cables to Keep North America‘s Military and Law Enforcement in Constant Contact

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.