Ultra-low profile and Ultra-large current Co-fired power inductor-HTF series with an Ultra-low Loss and Ultra-large Current

Ultra-low profile and Ultra-large current Co-fired power inductor HTF series products adopt innovative copper magnetic Co-fired technology, which can achieve higher characteristics in the same size or achieve equivalent performance in smaller sizes compared to similar products. It has an ultra-low loss, and ultra-large current, and has the ability to be much thinner in the overall dimension design. Its unique copper magnetic co-firing process ensures excellent heat dissipation characteristics and high reliability. Due to the advanced production process, it has the advantages of both molded and assembled power inductors, it can be used to produce small-size but large current inductors and large size meanwhile large current ultra-thin inductors. Regarding the application, it can support single coil DC-DC power supply and coupling inductor for multi-phase power supply applications.

It is especially suitable for some ultra-thin high-power applications, as well as scenarios with high requirements for heat dissipation and reliability. Its unique advantages are incomparable to those of molded inductors and assembled inductors.

Application

●The CPU power supply in high-end PC, Pad, and other applications uses ultra-thin features to improve the equipment cooling system.

●The CPU, GPU, and related circuits in servers, AI servers, and other high-current and ultra-thin applications for the power supply. The ultra-thin high current can deal with the VRM and TLVR power supply scheme, and reduce the board area through back PCB mounting.

Background

Small size, big trust. With the trending of low profile for AI servers, high-end PCs, Pads, mobile phones and other products, as well as the inherent requirements of high power. It has a huge impact on the size and power consumption of internal components. Meanwhile, the DC-DC circuit, as the power supply, subjected to the market request, needs to achieve ultra-low profile while maintaining high power. Which, of course, depending on direct current flow capacity of the power inductor. The ultra-thin ultra-large current copper magnetic Co-fired power inductor came out at the historic moment.

At the same time, accompany with high reliability, high heat dissipation capacity and low loss are also deemed to become the highlights of copper magnetic Co-fired inductor.

Features

●Have incomparable ultra-thin advantages

●Ultra high reliability

●Wide operating temperature range, no long-term high temperature aging problem

● High saturation current characteristic

●Ultra low RDC, lower loss and higher power conversion efficiency

●Wide operating frequency range

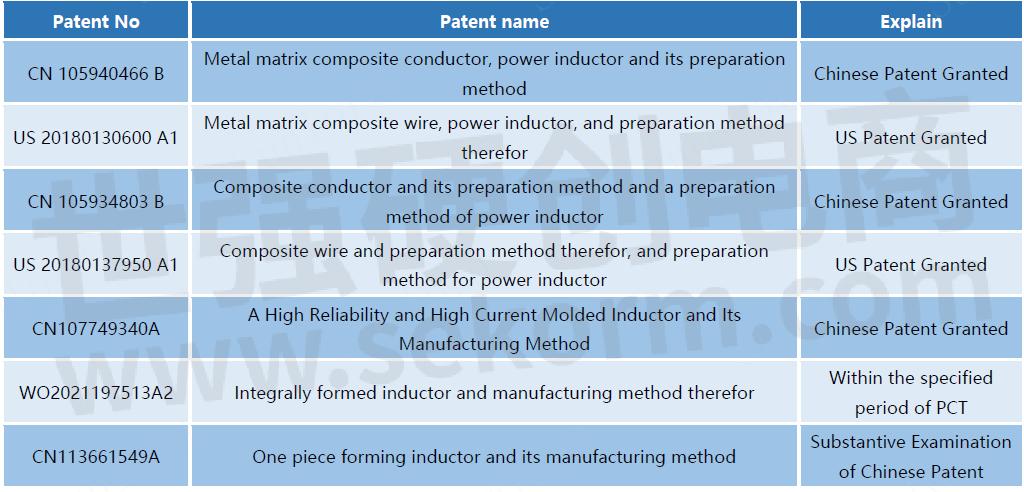

●HTF series inductors use SUNLORD's unique copper magnetic co-firing technology and have several patents

Table.1

Comparison of Product Advantages

●Comparison of material properties:

Compared with low-temperature solidified alloy powder, sintered alloy powder has:

High permeability( μi)

High saturation magnetic induction (Bs)

High thermal conductivity

Ultra low core loss

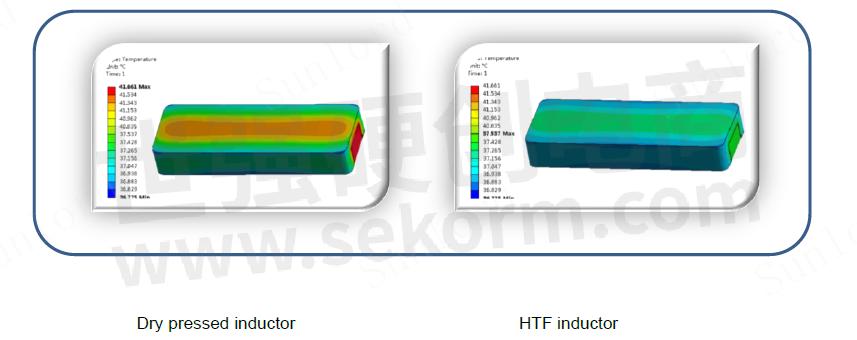

●Temperature rise simulation:

Under the same power consumption, the surface temperature of HTF inductor is 10% lower than that of dry voltage inductor

Fig.1

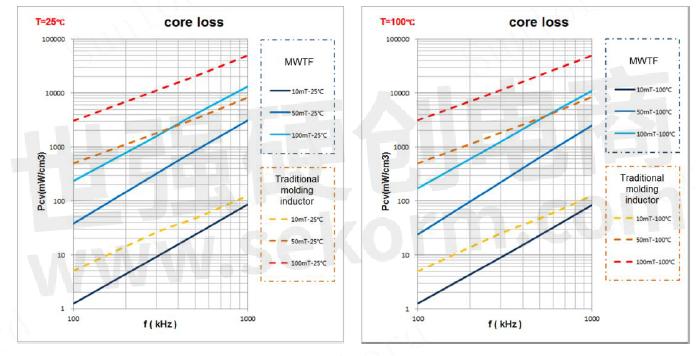

●Core Loss:

In the same test setup, at 25℃ and 100℃, the Core loss of HTF series products is lower than that of dry pressed products.

Fig.2

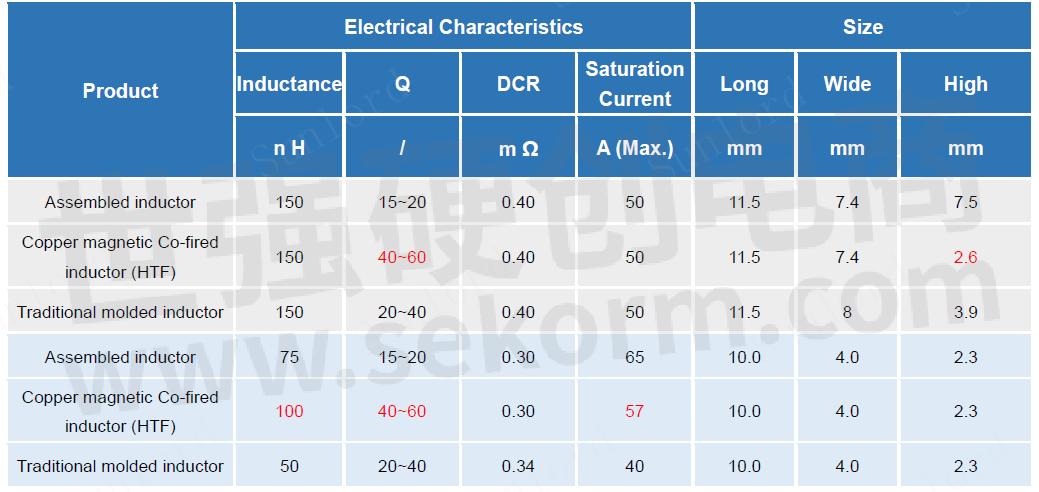

●Electrical characteristics and size comparison:

Under the same electrical conditions, the height of HTF series inductors is 50~60% lower than that of assembled inductors, and 30~40% lower than that of traditional dry pressed molded inductors;

Under the same size conditions, the inductance and Q value of HTF series inductors can be 1.5~2.0 times compared than the assembled inductors and traditional molded inductors.

Table.2

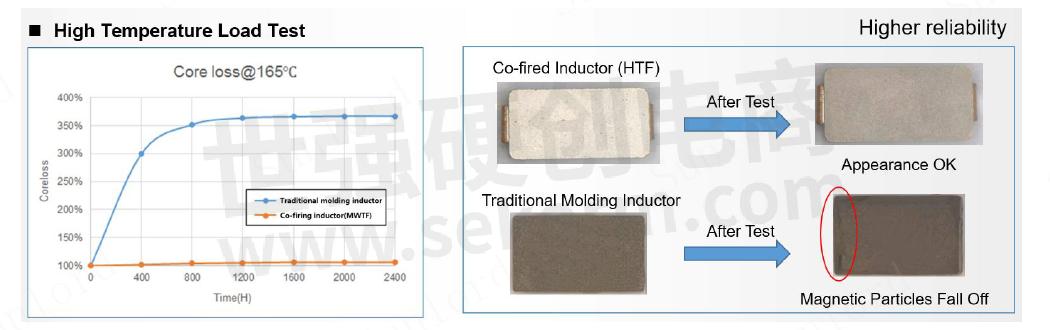

●High temperature load test:

After the high temperature load 2400H test, the increase rate of HTF loss fluctuates at 10%, and the increase rate of dry voltage inductance loss is more than 350%;

After the high temperature load 2400H test, the HTF has a good appearance, and the dry pressed inductor has a large area of magnetic particle falling off.

The magnetic powder used for dry pressed inductor contains a lot of organic substances, which will age and become invalid under high temperature. The reliability of product characteristics is low and the strength of the product is insufficient, and the magnet is easy to fall off; HTF series products effectively avoid such problems.

Fig.3

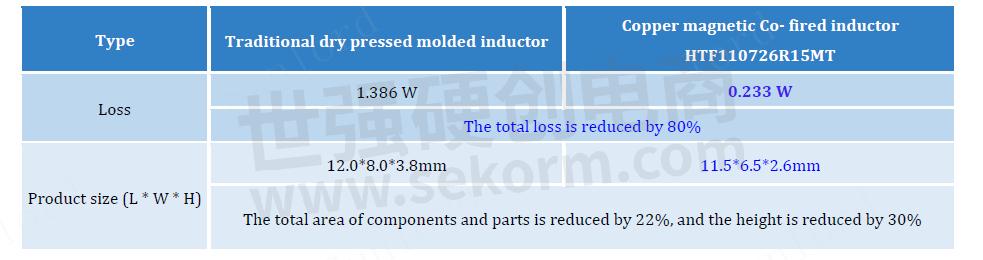

●Ultra low loss:

It can minimize the total loss of terminal products and improve the conversion efficiency

Table.3

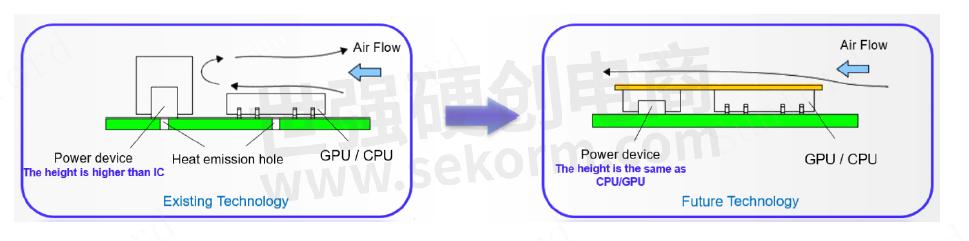

●Ultra-low profile features:

The product is ultra-low profile to make it highly compatible with IC;

The overall heat dissipation performance of the terminal product can be improved to a certain extent by improving the heat dissipation duct. Be able to adding heat dissipation plates, and utilizing the high thermal conductivity freely by using the copper magnetic Co-fired inductor.

Fig.4

Applications

●VRM and TLVR power supply of server CPU, GPU, FPGA, etc

●Power supply for ultra-thin Notebook and Pad

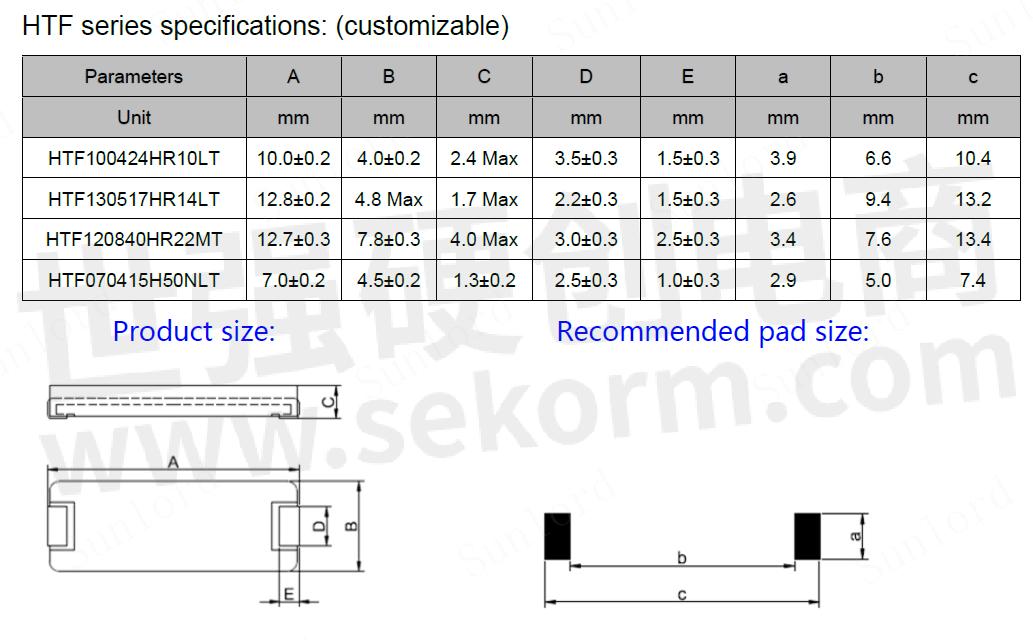

Dimensions

Fig.5

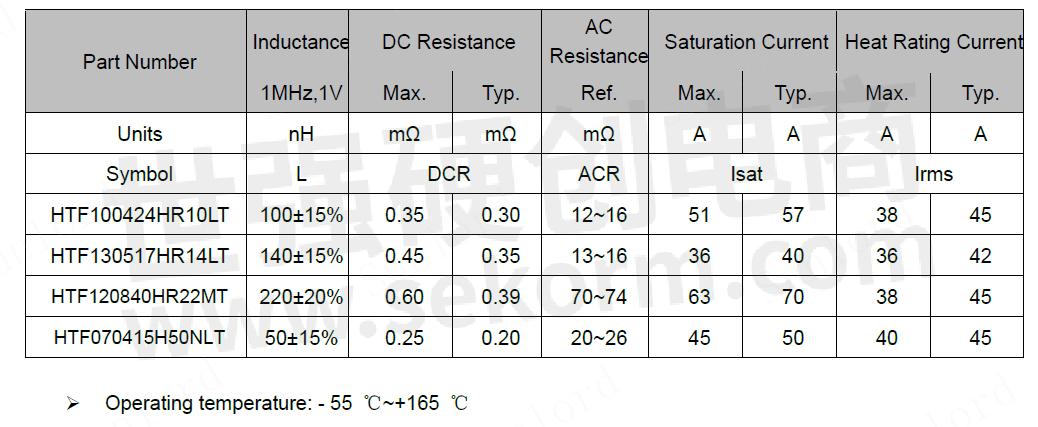

Part Number

Table.4

Production

●Sample can be sent at any time

●Mass production import stage

- 【Datasheet】HTF series Ultra-low profileand Ultra-largecurrent Co-fired power inductor New Product Launch

- 【Datasheet】HTF Series Co-fired Alloy Power Inductor

- +1 Like

- Add to Favorites

Recommend

- Sekorm Became an Authorized Distributor of Sunlord

- High-current Ferrite Beads for Audio Devices and GaN Fast Charging—MZPA Series from Sunlord

- Small but Powerful!Sunlord High Q Value 008004 (inch) Size Multilayer RF Inductor Released—HQ0201Q Series

- Sunlord High Power Reactors UU Series Provide the Improved Performance by More Than 10% for PV Energy Storage

- Sunlord Developes High-performance of MWPU Series Power Inductor for Wearables

- Sunlord Newly Developed a Ceramic Dielectric Filter-VFCF Series,Which Covers the Sub-6G Frequency Band of Domestic 5G Base Stations

- Sunlord developed AMWPB Series Wire Wound SMD Power Inductors for Automotive combined with the BASE card wire laser welding process

- Sunlord Releases Tantalum Capacitors with New Electrode Structure, Optimized in Size and Electrical Performance

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.