Sunlord Releases Tantalum Capacitors with New Electrode Structure, Optimized in Size and Electrical Performance

Product images

Overview

Tantalum Capacitors are mainly used in automotive electronics, consumer electronics, civil explosion, server, data center, SSD, AI and other industries. With the progress of science and technology, various industries are constantly developing, and the traditional structure products, that with lead frames, have been unable to meet the development needs of customers due to their disadvantages such as large size, low reliability, large leakage current and high ESR performance. In order to meet the new needs of miniaturization, thinning, high reliability and high performance in various industries, SUNLORD has developed new structure products which is no lead frame to reduce size and improve electrical performance: TP series polymer tantalum capacitors and TM series MnO2 tantalum capacitors.

Background

The electronic products in the consumer market, such as smartphones, tablets, and wearables, are becoming increasingly small and thin. While maintaining their original capacity and voltage, traditional structured tantalum capacitors are unable to reduce product thickness to meet customer needs. In addition, the precision requirements of electronic detonator control modules are becoming increasingly high. Traditional structured tantalum capacitors have large leakage current and short power down time, which cannot meet the high-end product needs of customers. Tantalum capacitors are also widely used in servers. As the operating frequency and power of the server power supply increase, the ripple current in the circuit also increases. Traditional tantalum capacitors have a high ESR, which leads to insufficient ripple resistance and can easily cause thermal failure of the product.

Based on the above background, Sunlord new type of electrode structure tantalum capacitor has been optimized in terms of material, structure and process, and its size and electrical performance have been greatly improved compared with the traditional structure tantalum capacitor.

Features

Ultra-thin and high volumetric efficiency

Low ESR, good resistance to ripple current

Low leakage current and low self-heating

Self-healing capability and high reliability of polymer tantalum capacitors

Applications

Severs, SSD, etc.

Electronic detonators

Laptops, tablets

Robots, medical equipments, UAV

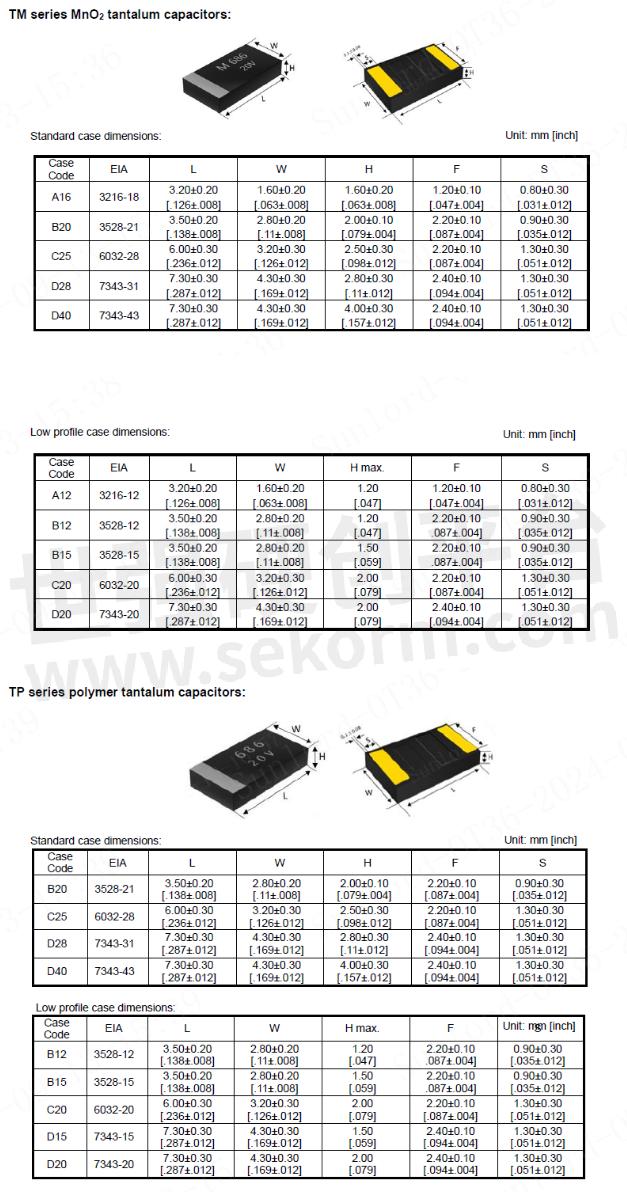

Shape and Dimensions

Product Advantages

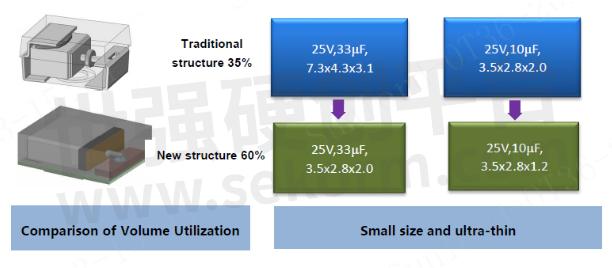

High volumetric efficiency, small size and ultra-thin

The volume utilization rate of traditional tantalum capacitors is 25% lower than that of the new electrode structure products due to the large area of plastic packaging and lead-frame bending structure outside the tantalum core, so the new electrode structure tantalum capacitors can be miniaturized and thinner.

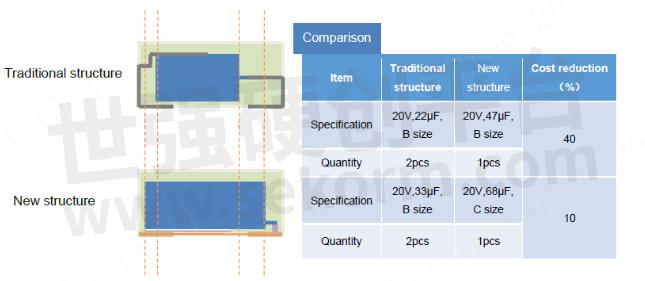

High voltage resistance and large capacitance

In the same package volume, the new structure T-cap can increase the length of tantalum pellet and increase the amount of tantalum powder filling.

According to the formula CV= specific volume*powder weight, when the specific volume is constant, powder weight increase is equivalent to CV value increase. Therefore, the C value and/or V value can be increased, to achieve higher voltage and larger capacitance.

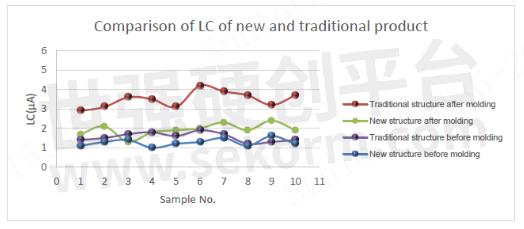

Low leakage current

1. The new structural T-caps adopts Compress Molding with low pressure which reduces the damage to the Ta2O5 dielectric layer and cathode film and avoids the deterioration of LC.

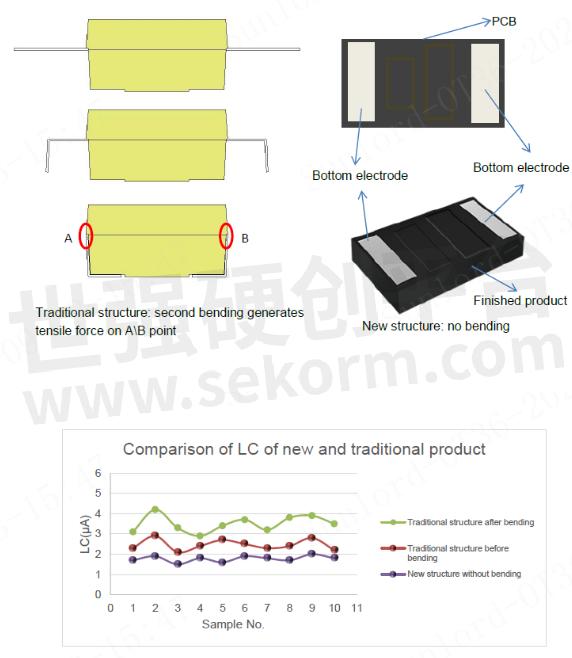

Comparison of LC of new and conventional product (25V, 33μF, C size):

After molding, the LC of conventional structure T-cap changes from 2.67μA to 5.45μA and increases by 104%. However, the LC of new structure T-cap changes from 2.57μA to 3.72μA, and only increases by 45%.

2. The new structure products use the bottom electrode of the PCB board, without bending.

Comparison of LC of new and conventional product (25V, 33μF, C size):

After bending, The LC of conventional structure T-cap changes from 2.58μA to 3.17μA and increases by 23%. The new structure is the bottom electrode, without bending, and the LC does not change.

Production

Mass production.

- +1 Like

- Add to Favorites

Recommend

- Sekorm Became an Authorized Distributor of Sunlord

- High-current Ferrite Beads for Audio Devices and GaN Fast Charging—MZPA Series from Sunlord

- Small but Powerful!Sunlord High Q Value 008004 (inch) Size Multilayer RF Inductor Released—HQ0201Q Series

- Sunlord High Power Reactors UU Series Provide the Improved Performance by More Than 10% for PV Energy Storage

- Sunlord Developes High-performance of MWPU Series Power Inductor for Wearables

- Sunlord Newly Developed a Ceramic Dielectric Filter-VFCF Series,Which Covers the Sub-6G Frequency Band of Domestic 5G Base Stations

- Sunlord developed AMWPB Series Wire Wound SMD Power Inductors for Automotive combined with the BASE card wire laser welding process

- Sunlord Developed the PQ34 High-frequency Transformer Series of Main Transformers for Residential Photovoltaic Microinverters

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.