Can Your DRAM Withstand Wide-Temp Operating Conditions?

Whether your systems are installed or deployed in cities or remote locations, constant operation, heavy workloads, space constraints, and rugged environments can pose thermal challenges. Extreme heat or extreme cold can damage components and cause systems to fail, thus leading to breakdowns and costly disruptions.

Memory plays a critical role in any computing system, especially for those that require high reliability and availability while operating under rapid thermal cycling. Such applications require industrial-grade memory modules made with native industrial-grade integrated circuits (ICs) that are rated to operate at the industrial temperature range of -40℃ to 85℃.

Extreme Temp Environments

Applications that typically process huge amounts of data at high speeds encounter heat issues due to their workloads and the environments where they are deployed.

5G DU/CU/MEC, Networking Servers

A 5G Open Radio Access Network (O-RAN) architecture consists of functional components that connect users to the mobile network over radio waves, including distributed unit (DU), centralized unit (CU), and mobile edge computing platform (MEC) servers that require high reliability and low latency. Servers face constant thermal challenges due to numerous and high-performance components packed in a compact chassis.

Challenges:

They run on Intel® Xeon® or AMD central processing units with high core counts. With higher computational power, they also consume more power and generate more heat, especially under heavy workloads, if the airflow is insufficient, and if internal cooling is inefficient.

As more components share the limited space within the chassis, there is less airflow within DIMMs.

They are installed within very limited or constrained spaces without air conditioning, resulting in high humidity levels.

Even with air conditioning, the server cabinet may still have elevated temperatures.

Bus/Truck/Fleet/Public Transportation Gateways

Digital advances are driving today's business transporters and public transportation systems, enabling connected monitoring and management. Passenger and driver experiences are also being enhanced with the delivery of greater comfort, safety, and infotainment by staying connected while on the move. In-vehicle gateways provide high-speed connectivity and real-time data processing to and from various transportation networks as well as functional domains within the vehicle. With more modern business and public transporters using electrical features, gateways enable more efficient in-vehicle control, asset/fleet monitoring, and driver behavior monitoring, and offer connectivity to various hardware devices and other subsystems within the vehicle.

Challenges:

Increasing vehicle electrification is also leading to increasing thermal challenges as high power consumption leads to higher heat flow and component temperature.

Vehicles traversing areas with shifting climates and extreme temperatures need operational reliability to ensure passenger comfort and safety.

Railway Computers

Smart railway infrastructures incorporate high-performance computer systems for passenger information, entertainment, railway controls and management, video surveillance, and other function-critical applications.

Constant operation requires reliable performance even in harsh environments.

Component overheating within the chassis.

Rail track temperatures in extreme conditions.

When a train park at the yard during non-service hours at freezing temperatures, upon resuming operations, the DRAM without wide-temp support will fail at boot-up.

Extreme heat or cold can short out major components, put the train out of service, and cause service delays.

Other Industries Requiring Wide-Temp Solutions

Aside from the above-mentioned industries, other industries that may experience extreme temperatures and harsh environments that could prove detrimental to DRAM modules include aerospace, agriculture, telecom, and more. These applications typically require wide-temp solutions as systems are installed in waterproof, fanless enclosures and operate in environments with limited ventilation.

Is Commercial-Grade Memory Suitable?

While industrial-grade DRAM modules are the preferred memory solutions for systems deployed in harsh environments with extreme temperature shifts, they could be very expensive; hence, many companies resort to using commercial-grade DRAM, which is not suitable and may even prove more detrimental in the long run.

Aside from the actual cost of the modules, technicians may have to travel to remote sites to replace the modules and operations must halt while awaiting replacement. These all translate to huge losses.

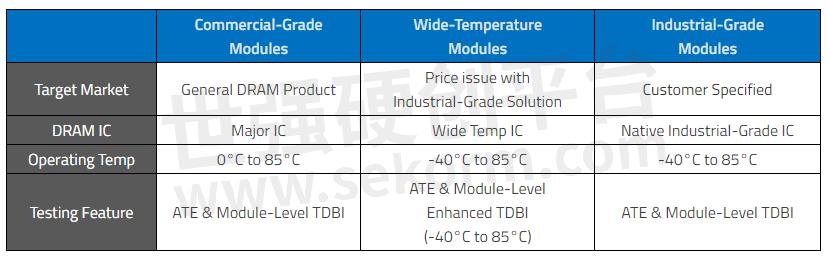

ATP Wide-Temp Solutions vs. Other Industrial Temp DRAM

ATP Electronics understands that businesses need to optimize ownership and operational costs and have come up with the ideal solution: wide-temperature DRAM modules that can operate reliably at -40℃ to 85℃ but at lower costs. Through rigorous testing, ATP is able to offer wide-temp DRAM modules that achieve the best balance between the optimal total cost of ownership (TCO) and long-term reliability.

Compared with other WT DRAMs in the market, ATP uses exclusive IC-level and system-level testing that also provides superior system-wide stability.

ATP Enhanced Module-Level Testing for Wide-Temp DRAM

ATP's stringent testing for its WT DRAM solutions consists of enhanced module-level TDBI and ATE. Through accelerated testing methods, ATP significantly lowers failure rates and extends the product service life by making sure that only robust DRAM chips are on the module. Even just a 0.01% error on a 99.99% effective device can increase the failure rates at the module level and lead to failure in actual usage, TDBI detects and screens out up to 0.01% error to ensure the DRAM modules' reliability.

Test During Burn-In (TDBI) and Automatic Test Equipment (ATE) guarantee that modules meet and even exceed qualifying parameters.

Functional Testing Using Automatic Testing Equipment (ATE).

The ATE detects component defects and structural defects related to the DIMM assembly and screens out marginal timing and signal integrity (SI) sensitivities. The ATE testing system can pinpoint individual defective ICs or DRAM PC boards, thus providing a more efficient failure analysis method for both new product development and mass production stages.

System-Level Failure Detection and Prevention via TDBI.

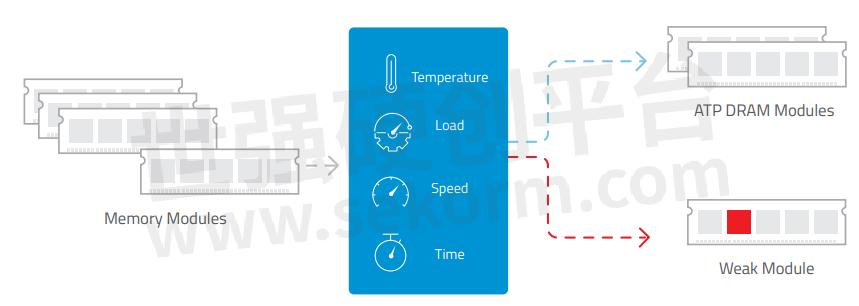

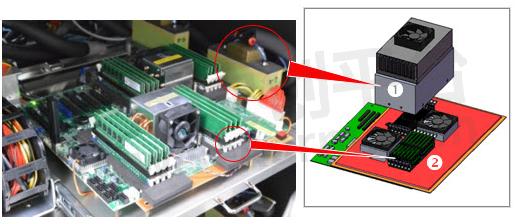

The ATP TDBI system applies extreme high/low temperature, high-low voltage, and pattern testing on DRAM modules. ATP TDBI combines temperature, load, speed, and time to stress test memory modules and expose weak modules. ATP's system-level TDBI can detect and screen out the 0.01% error to ensure the utmost reliability. The system consists of:

1. The miniature chamber, which isolates temperature cycling only to the module being tested so as not to thermally stress the rest of the testing systems. This minimizes the failure of other testing components, such as the motherboards. In conventional large thermal chambers, the failures of non-DRAM-related testing components are constantly given that the whole system is thermally stressed.

2. Module riser adapters from the motherboard, which allow easy module insertions in production-level volumes.

Conclusion: Why You Need ATP's Wide-Temp DRAM Solutions

In operating environments where temperatures could be extremely cold or hot, commercial-grade DRAM solutions may not be enough, and may even prove detrimental in the long run. On the other hand, DRAM modules that are I-Temp operable are ideal but are very expensive. To get the best balance between quality, reliability, and longevity at friendlier price points, ATP's WT DRAM modules offer the optimal solution.

Below are some of the reasons why you need ATP's WT DRAM solutions:

Waterproof, no air conditioning, fanless environments.

Even if there is air conditioning, wide-temp DRAMs have a longer life.

Systems running non-stop 24/7 must not fail.

The cost of replacing or fixing an appliance can be more than the cost of wide-temp DRAMs.

For life-critical applications, human life may be at stake if the system fails.

Systems run for over 10 years. ATP WT DRAMs have 5 years + fixed BOM longevity.

- +1 Like

- Add to Favorites

Recommend

- Managing DRAM Supply in the Quarters Ahead

- DRAM: How to Pick the Right Embedded Memory?

- Building AI Servers with DRAM for Artificial Intelligence

- Alliance Complete Automotive Temperature DRAM Portfolio, Now With Reduced Lead Times

- Understanding RAM and DRAM Computer Memory Types

- The Road Ahead: DRAM Fueling Automotive Trends

- Alliance Memory Expanded Low-Power SDRAM Portfolio and Offered LPSDR, LPDDR, and LPDDR2 Devices in Wide Range of Densities and Package Options

- The Important Role of DRAM in the Internet of Things

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.