Xiangru Electronic XRACM-7060F-501 Common Mode Choke Integrates Miniaturization, High Reliability and Excellent EMI Suppression Ability

Outline

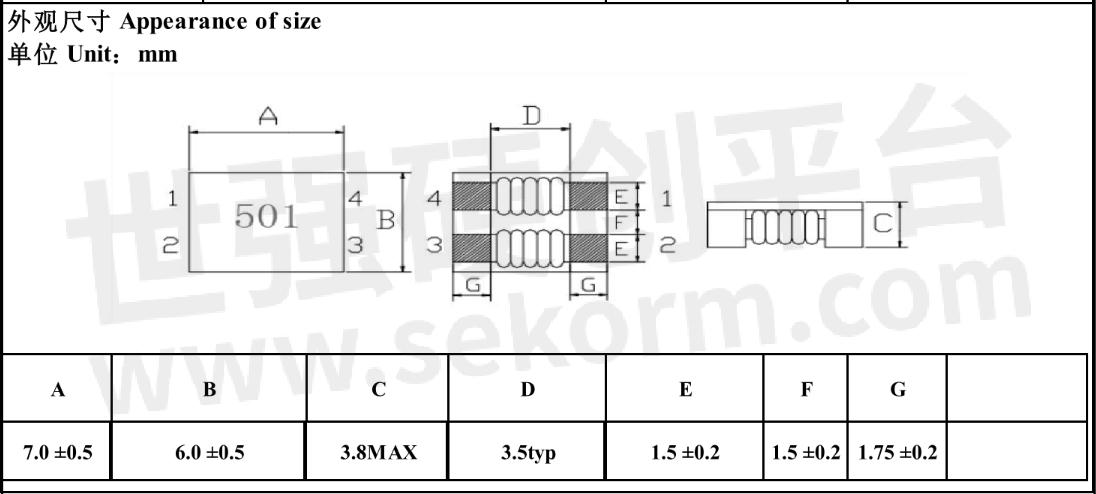

The XRACM series XRACM-7060F-501 designed by XIANGRU ELECTRONICS with high reliability and miniaturization has been put into mass production in common mode choke. The product adopts high-performance iron core materials and wires, which ensures the high reliability of the product and realizes compact design and wide applicability. Its size is 7.0mm x 6.0mm, which is suitable for high-frequency common-mode signal processing circuits in electronic equipment, such as position detection, signal transmission and noise suppression.

Background and Development Purpose

With the progress of electronic technology, the functions of equipment are becoming more and more complex, and the integration of circuits is constantly improving. The problem of electromagnetic compatibility (EMC) has become a key challenge. Power lines and signal lines are easily affected by common-mode interference, which may weaken the performance of equipment and even lead to damage. Common mode choke, as an effective solution, can suppress this kind of interference, thus enhancing the stability and reliability of equipment, and has been widely used in a variety of electronic equipment. Xiangru Electronics Co., Ltd. responded to the market demand and devoted itself to improving the EMC performance of electronic equipment, and launched XRACM-7060F-501 common mode choke, aiming at providing customers with high-quality and reliable EMC components and supporting their needs in the design and manufacturing process.

Product Features

Efficient EMI suppression: specially designed to suppress electromagnetic interference, suitable for application scenarios that need to improve electromagnetic compatibility.

Wide temperature operation: it can work stably in the temperature range from-30℃ to+100℃, and is suitable for various environmental conditions.

High reliability: it has been strictly tested in many aspects and adapted to different environments.

Miniaturization: the size is 7.0mm* 6.0mm.

Application

Consumer electronics: smart phones, tablets, laptops and other portable devices.

Computers and peripheral equipment: desktops, servers, monitors, etc.

Network communication equipment: routers, switches, etc.

Medical equipment: monitors, ultrasonic equipment, etc.

Industrial control: automatic control system, frequency converter, etc.

Power electronics: UPS, solar inverter, etc.

Household appliances: washing machines, refrigerators, air conditioners, etc.

Appearance and Size

Specification Characteristics

Product Advantage

Efficient EMI Suppression

XRACM-7060F-501 has a DC resistance (DCR) as low as 10mΩ and an impedance as high as 350Ω (at the frequency of 100MHz), which means that it can effectively suppress high-frequency electromagnetic interference (EMI), thus ensuring the signal integrity and overall performance of the system.

Miniaturization Design

Although its rated current reaches 5.0A, the device still maintains a compact overall size of only 7.0mm x 6.0mm, which makes it an ideal choice for those applications with limited space but strong EMI suppression capability.

Excellent Reliability

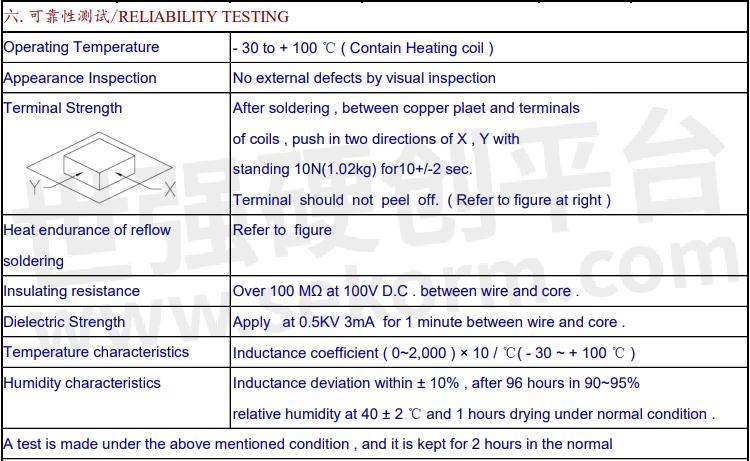

1. Wide Temperature Adaptability

The working temperature range is-30℃ to+100℃ (including the heating coil), which means that the product can maintain normal working conditions under cold and hot environmental conditions, ensuring the stability of electronic equipment in different temperature environments.

2. Stable Mechanical Properties

The terminal strength test shows that after welding, the terminal bears a force of 10N (about 1.02kg) in both X and Y directions, and will not peel off for 10 2 seconds. This good mechanical performance ensures that the connection part of the product is still stable even if it is subjected to a certain external force during use, and will not affect the normal connection and work of the circuit.

3. Reliable Electrical Performance

The insulation resistance is more than 100 mω between the wire and the core at 100V DC, which ensures good insulation effect and prevents short circuit.

The dielectric strength meets the requirements under the condition of 0.5KV and 3mA for 1 minute, which further verifies the safety and stability of the product under certain voltage.

The temperature and humidity characteristics also meet the standards. After 96 hours of 90-95% relative humidity, 40 2℃ and 1 hour of normal drying, the inductance deviation can be controlled within 10%, which ensures the stability of the products in different humidity environments.

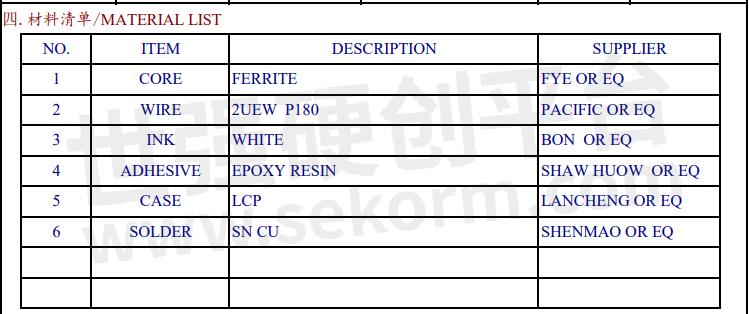

High Quality Materials

The bill of materials covers many key materials, such as CORE FERRITE and WIRE, and each material has a clear description of the supplier or equivalent material, such as CORE FERRITE from FYE or equivalent supplier, WIRE using 2EWP180, PACIFIC or equivalent supplier, etc. These high-quality materials provide a basic guarantee for the high performance of products.

Produce

Mass production

- +1 Like

- Add to Favorites

Recommend

- Integrally Formed Inductor Recommended for TWS Earphones: XRTC252012S2R2MBCA from Xiangru Electronics Has a Low DC Resistance of Only 65mΩ

- The Xiangru Electronics XRT953B-351M Common Mode Toroidal Inductor Provides Excellent EMC Performance for Charging Station Products

- Xiangru Electronics XRSQ1010-10mH-H High Performance SQ Flexible Flat Cable Common Mode Choke, Helping the Miniaturization Design of Power Products

- Xiangru Electronics Introduced the Unshielded Inductor XRCD32-220K, with a Size of Only 3.5*3.0*2.1mm, Which Helps the Small and Lightweight Design of Products

- Xiangru Electronics Introduced an Integrated Inductor XR0630-4R7M, with a Maximum Dc Resistance of Only 42mω and a High Saturation Current of 7A

- XRTC252012S2R2MBCA Integrated Inductor Introduced by Xiangru Electronics Has a DC Resistance as Low as 55mΩ, Realizing Low Loss

- Design of Ultrasonic Drive Circuit for Xiangru Electronic Patch Transformer with Limited Assistance Space is Only 9*7*6.7mm in Size

- What Is A Common Mode Choke?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.