Integrally Formed Inductor Recommended for TWS Earphones: XRTC252012S2R2MBCA from Xiangru Electronics Has a Low DC Resistance of Only 65mΩ

Bluetooth earphones have freed users from tangled wires and have become the preferred choice for consumers due to their convenience and ease of use. With the booming development of the TWS earphone market, major consumer electronics brands are accelerating their entry into this field. In the fierce market competition, manufacturers are increasingly demanding higher performance from the internal components of TWS earphones to enhance product functionality and user experience.

Although small in size, Bluetooth earphones are fully equipped with rich features. They offer touch control, single-ear connection, active noise cancellation, and can be repeatedly charged. Achieving these functions requires the integration of power sources, such as DCDC buck power supplies for the entire system, fast-charging power supplies for the built-in battery, and power supplies for charging the earphones. These switching power supply chips need to be paired with 1-2 power inductors, and integrally formed inductors are the preferred material due to their functionality and characteristics.

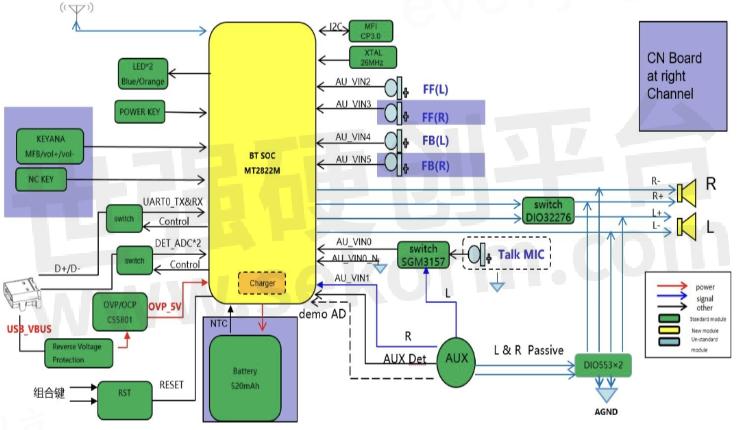

Bluetooth earphone system block diagram

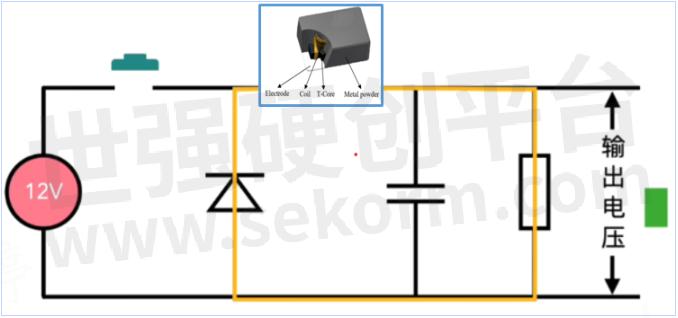

Block diagram of the switching power supply for Bluetooth earphones

In the application of switching power supplies and charging circuits in Bluetooth earphone products, it is recommended to use the integrally formed inductor XRTC252012S2R2MBCA from XIANGRU ELECTRONICS, which is a relatively good solution. The advantages are as follows:

Harmlessness

The integrally formed inductor is halogen-free and complies with RoHS standards, ensuring a safe and skin-friendly experience for Bluetooth earphone users.

Miniaturization

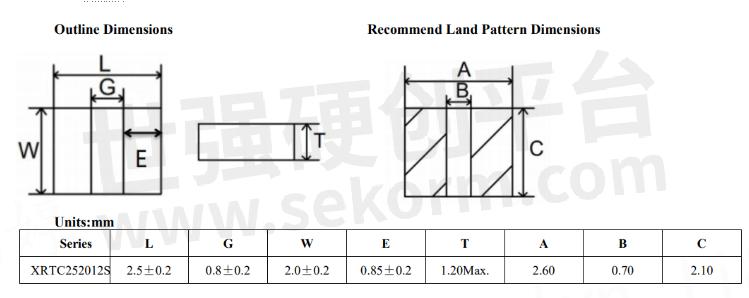

The integrally formed process results in a small inductor size of only 2.5*2.0mm, with a sturdy and relatively flat structure. In compact spaces like Bluetooth earphones, it reduces the circuit board area occupied inside TWS earphones, enabling smaller product designs.

Rust Resistance

The integrally formed inductor uses thermal spraying technology to provide long-lasting rust resistance, ensuring the longevity of Bluetooth earphones.

Excellent Electrical Performance

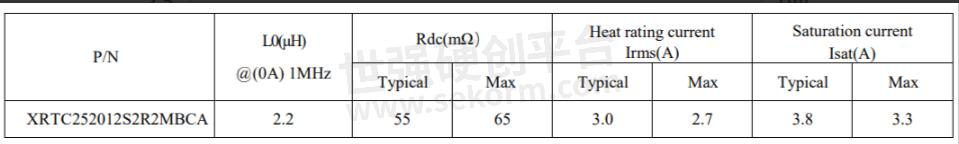

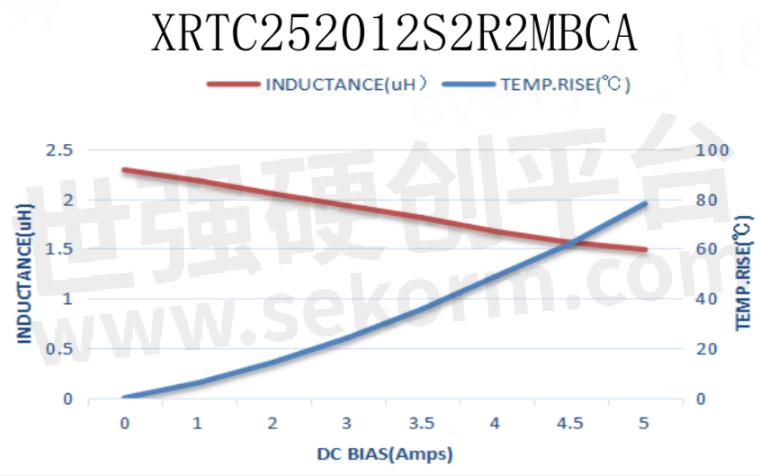

The XRTC252012S2R2MBCA from Xiangru Electronics features low impedance (maximum DC resistance Rdc of only 65mΩ), a temperature rise current of up to 2.7A, and a saturation current of up to 3.3A. This indicates that the product can maintain excellent temperature rise and saturation current characteristics under high temperatures. Based on these characteristics, it can improve the efficiency of switching power supply circuits in Bluetooth earphone products, effectively reduce energy consumption, and enhance the device's battery life.

Good Shielding, Optimizing Whistling Issues

The human ear can recognize sound frequencies in the range of 20Hz to 20kHz. If the power switch frequency falls within this range, it can cause inductor whistling. For products like Bluetooth earphones that are sensitive to sound experience, integrally formed inductors can optimize whistling issues due to their shielding properties. At the same time, it reduces the overall outward radiation energy, which can reduce EMC interference within the earphone cavity and prevent noise interference.

In summary, the integrally formed inductor XRTC252012S2R2MBCA plays an important role in the design and manufacture of Bluetooth earphones due to its unique advantages and characteristics. It not only enhances the performance of the earphones but also improves the user experience.

Additionally, the integrally formed inductor XRTC252012S2R2MBCA is widely applicable to various portable mobile terminal products such as smartphones, power banks, portable game consoles, smart wearables, WiFi modules, and laptops.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.