Ultra-thin MWPH Series Power Inductor for TWS Earphones, with Higher Q Value and Lower Loss

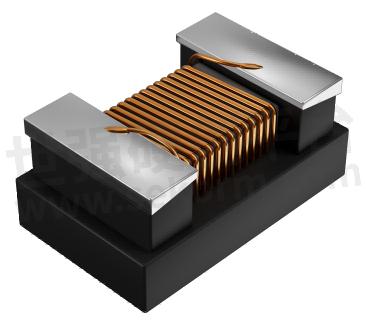

Product images

Overview

With the evolution of Bluetooth, chips, sensors and other technologies, the design of TWS earphones is becoming smaller and thinner, and the performance and size requirements of the inductor are also increasing. Compared with the conventional winding inductor, the open magnetic circuit design is optimized to semi-magnetic shielding, which reduces magnetic leakage to decrease the impact on other devices, and lessen the noise of TWS earphones. At the same time, the core material is optimized to effectively improve the current capacity, compared with the open-circuit winding inductor, the saturation current is increased by >30% and the loss is reduced by nearly 30%. The size of MWPH series ranges from 1.0*0.5mm to 1.6*0.8mm, and the inductance range is 0.33μH to 22μH. MWPH series is widely used in consumer electronics and portable medical equipment such as TWS earphones, smart watches, pads, etc.

Background

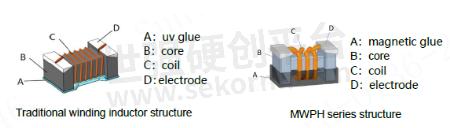

The traditional wire wound inductor is designed with an open magnetic circuit structure, which has large size and loss, while the new generation of wearable product design has higher requirements for product size and performance. Based on this background, SUNLORD Electronics relies on chip inductor platform to develop semi-magnetic shielded Power Inductor, using low-loss materials and high-precision coating processes to reduce the size and improve the product performance to meet the needs of the application side.

Features

Semi-magnetic shielded to reduce magnetic leakage.

Wide range of inductance (0.33μH~22μH), high Q, high SRF.

Ultra-thin and low profile, thickness 0f 0.5mm max.

Applications

Smart watches, TWS earphones, bracelets, etc

High-end mobile phone, Pad, etc

Small portable medical equipments

Shape and Dimensions

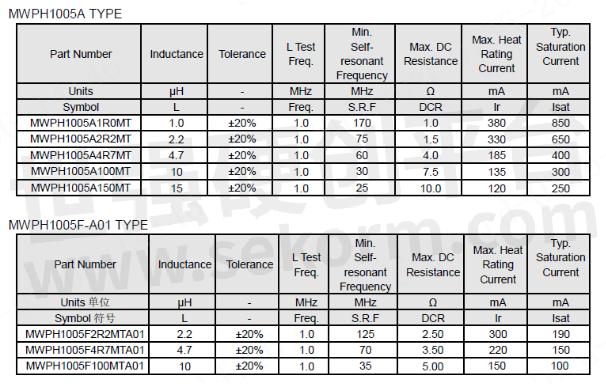

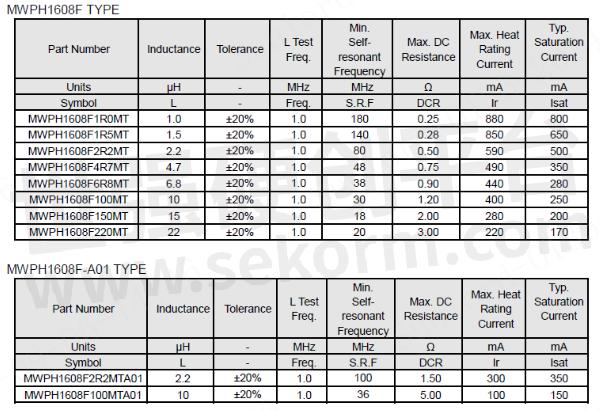

Electrical Characteristics

This part is the typical size & inductance, detailed information please refer to MWPH Series

New technology

Magnetic glue, semi-magnetic structure

The traditional winding inductor is coated with UV glue, which is an open magnetic circuit structure, only to protect the copper wire and facilitates the absorption of the customer's SMT. The MWPH series uses magnetic glue to reduce magnetic leakage while fixing the coil, reducing the bottom noise problem of TWS earphones.

High-precision dispensing control technology

The initial dispensing process uses air pressure dispensing, the glue fluidity is poor, resulting in the glue gathering together in the mold cavity, and lack of glue on the product body. After optimizing the formula of magnetic glue and adding control assembly design to the dispensing mechanism, the glue is easy to disperse and accurate dispensing is achieved.

Product Advantages

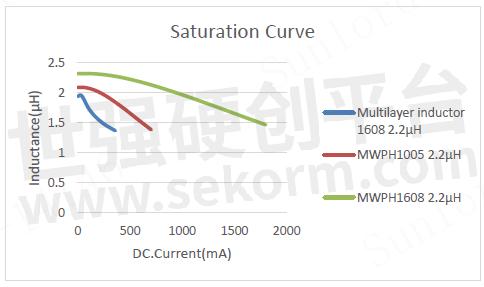

Smaller size and higher current compared with multilayer power inductors

Under the same size , the wire wound chip power inductor MWPH series has better saturation current, that is 350% higher than multilayer power inductors. Under the same inductance, the size of MWPH series is smaller, and the saturation current is still 60% higher than multilayer power inductors.

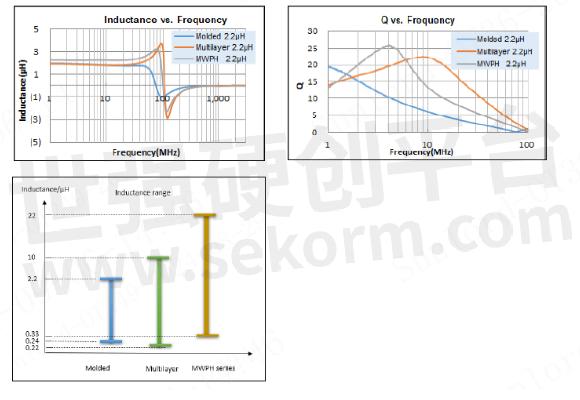

Higher Q and lower loss compared with molded power inductors

MWPH series has higher SRF, which can meet the higher frequency circuit applications. At high frequency, the Q value is higher and the loss is relatively small. And MWPH series has wider inductance range with 0.33μH~22μH.

Production

Mass production.

- +1 Like

- Add to Favorites

Recommend

- Sekorm Became an Authorized Distributor of Sunlord

- Sunlord Developes High-performance of MWPU Series Power Inductor for Wearables

- High-current Ferrite Beads for Audio Devices and GaN Fast Charging—MZPA Series from Sunlord

- Small but Powerful!Sunlord High Q Value 008004 (inch) Size Multilayer RF Inductor Released—HQ0201Q Series

- Sunlord High Power Reactors UU Series Provide the Improved Performance by More Than 10% for PV Energy Storage

- Sunlord Newly Developed a Ceramic Dielectric Filter-VFCF Series,Which Covers the Sub-6G Frequency Band of Domestic 5G Base Stations

- Sunlord developed AMWPB Series Wire Wound SMD Power Inductors for Automotive combined with the BASE card wire laser welding process

- Sunlord Releases Tantalum Capacitors with New Electrode Structure, Optimized in Size and Electrical Performance

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.