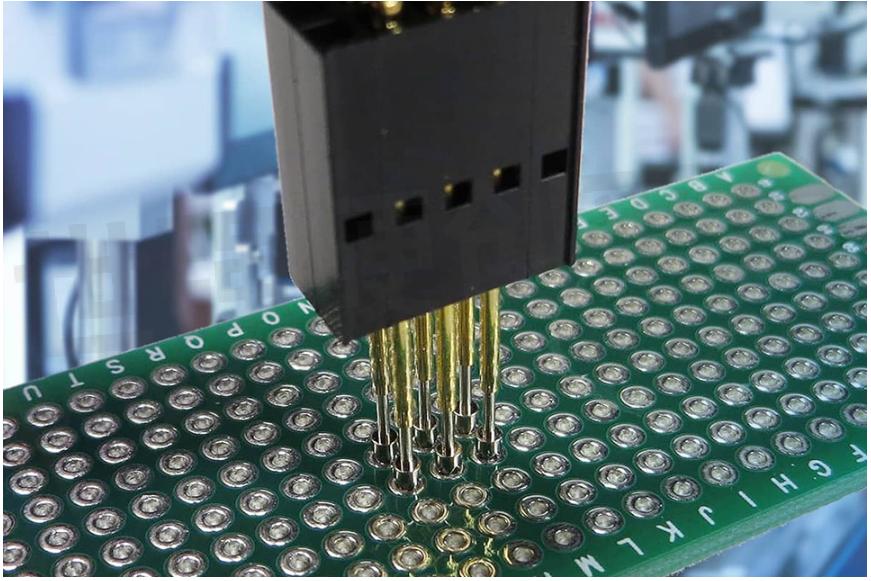

Machined Pin Header and IC Socket

A Machined Pin Header, also known as a machined pin connector, is a type of electrical connector commonly used in electronic systems to provide a reliable connection between a printed circuit board (PCB) and other components. It is primarily used for mounting integrated circuits (ICs) or other devices onto a PCB.

Machined pin headers typically consist of a plastic or metal housing with rows of evenly spaced metal pins or posts. These pins are designed to be soldered onto the PCB, providing a secure mechanical and electrical connection. The pin headers are available in various configurations, such as single-row, double-row, or even higher-density versions.

IC sockets are usually used in conjunction with machined pin headers. IC sockets provide a temporary connection between the IC and the PCB, allowing for easy insertion and removal of the IC without soldering. This can be beneficial during prototyping, testing, and when there is a need for component replacement.

The machined pin header and IC socket combination provide several advantages:

Easy Replacement: The use of IC sockets allows for easy replacement of faulty or damaged ICs without the need for soldering. This is particularly useful during the development, testing, and debugging stages.

Protection: IC sockets provide mechanical protection to the delicate pins of the IC. They help prevent damage to the IC pins during insertion and removal.

Flexibility: With machined pin headers and IC sockets, it is easier to swap different ICs on the same PCB, enabling flexibility in design and testing.

Testing and Programming: IC sockets facilitate the programming and testing of ICs by allowing them to be easily removed and reinserted, minimizing the risk of damage during these processes.

Machined pin headers and IC sockets are widely used in various applications, including consumer electronics, telecommunications, automotive systems, industrial equipment, and more. They provide a reliable and convenient solution for connecting and disconnecting ICs, enabling efficient assembly, repair, and maintenance of electronic systems.

In consumer electronics, machined pin headers and IC sockets are commonly found in devices such as computers, smartphones, tablets, gaming consoles, and home entertainment systems. These connectors enable the easy installation, removal, and replacement of ICs, facilitating repairs and upgrades.

Telecommunications equipment, including routers, switches, and communication modules, often utilize machined pin headers and IC sockets. These connectors enable the efficient assembly and testing of electronic components, allowing for quick replacement or upgrades in network infrastructure.

Automotive systems rely on machined pin headers and IC sockets for the connectivity and interchangeability of various electronic components. They are used in engine control units (ECUs), infotainment systems, powertrain modules, and other automotive electronics, enabling efficient maintenance and repair processes.

Industrial equipment, such as factory automation systems, robotics, and control systems, also benefit from the use of machined pin headers and IC sockets. These connectors provide a reliable and modular solution for connecting and disconnecting ICs, enabling streamlined assembly, troubleshooting, and maintenance in industrial environments.

Additionally, machined pin headers and IC sockets find applications in medical devices, aerospace systems, test and measurement equipment, and many other areas where efficient assembly, repair, and maintenance of electronic systems are crucial.

Their versatility, reliability, and convenience make machined pin headers and IC sockets essential components in the electronics industry, ensuring efficient and effective connectivity for a wide range of applications.

- +1 Like

- Add to Favorites

Recommend

- Nidec Machine Tool Develops Digital Twin Platform for Machine Tools

- Nidec Machine Tool Debuts CF26A, A Newly Developed Cutting Chamfering Machine, together with EdgeCut, A Dedicated Tool

- The Nidec Group’s Four Machine Tool Companies to Exhibit Products at CCMT2024 as Comprehensive Machine Tool Manufacturers to Meet All Industrial Fields’Needs

- Nidec Machine Tools Release “MVR-Cx“ :First Step Toward Expansion of Its Large-Scale Machine Tool Business

- Knowles Provides a High-Precision and High-Reliability Machined and Plated Solutions for Passive Electronic Components

- Nidec Launched “MVR-Hx”Series of Double-Column Machining Centers to Accelerate The Expansion of Its Large-Scale Machine Tool Business

- The Application of CW32F030 Series MCU in Electric Welding Machines

- Greenconn荣获邓白氏企业认证,实力彰显行业领先水平

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.