The Application of CW32F030 Series MCU in Electric Welding Machines

With the development of industrial technology, microcontrollers have played an important role in many fields. Applying a microcontroller in an electric welding machine can achieve automated control, improve welding quality and efficiency by writing specific programs.

Electric welding machine is a type of equipment used for metal welding, which uses arc heat to melt the metal and achieve welding. Electric welding machines are mainly composed of a power supply, a controller, and a welding head. The power supply provides high voltage and high current electrical energy, and the controller is responsible for controlling the power supply's on-off and adjusting welding parameters. The welding head converts electrical energy into heat energy, achieving metal melting and welding.

Electric welding machines can be divided into arc welding machines, fluorine arc welding machines, pulse welding machines, etc. according to their working principles. This article will introduce the application of Wuhan Core Source Semiconductor CW32F030 series microcontroller in arc welding machines.

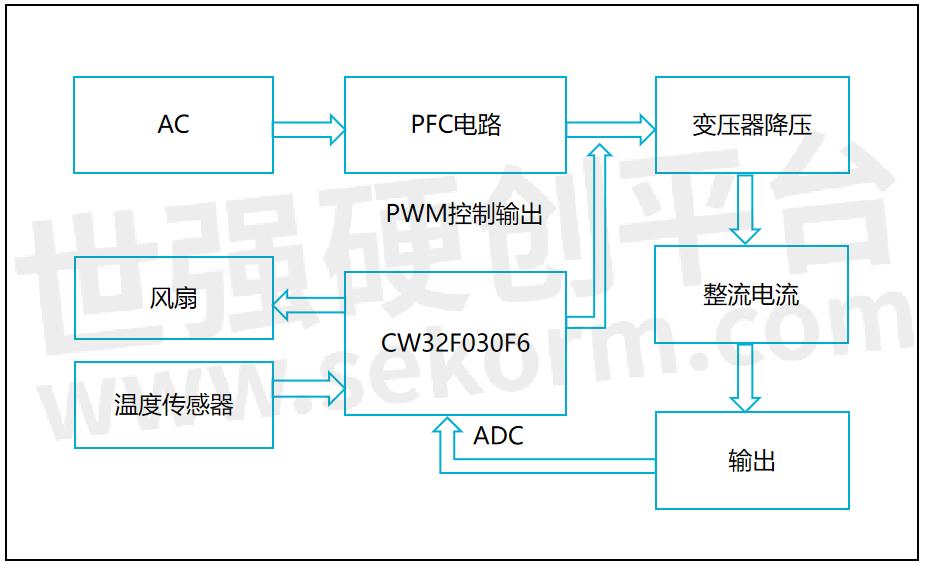

Application Block Diagram of CW32F030 Series MCU in Electric Welding Machines

Program features:

It can achieve automatic control of electric welding machines, and welding parameters can be set through input interfaces. The power supply can be controlled on/off and welding parameters can be adjusted through output interfaces to achieve automatic welding;

Real time monitoring of the welding process can be achieved by sampling and processing parameters such as welding current and voltage, enabling automatic detection and evaluation of welding quality to ensure welding quality;

Monitor and record the working status of the welding machine, which can achieve automatic fault diagnosis and alarm, facilitating repair and maintenance;

Controlling the power consumption of electric welding machines can achieve energy conservation and emission reduction.

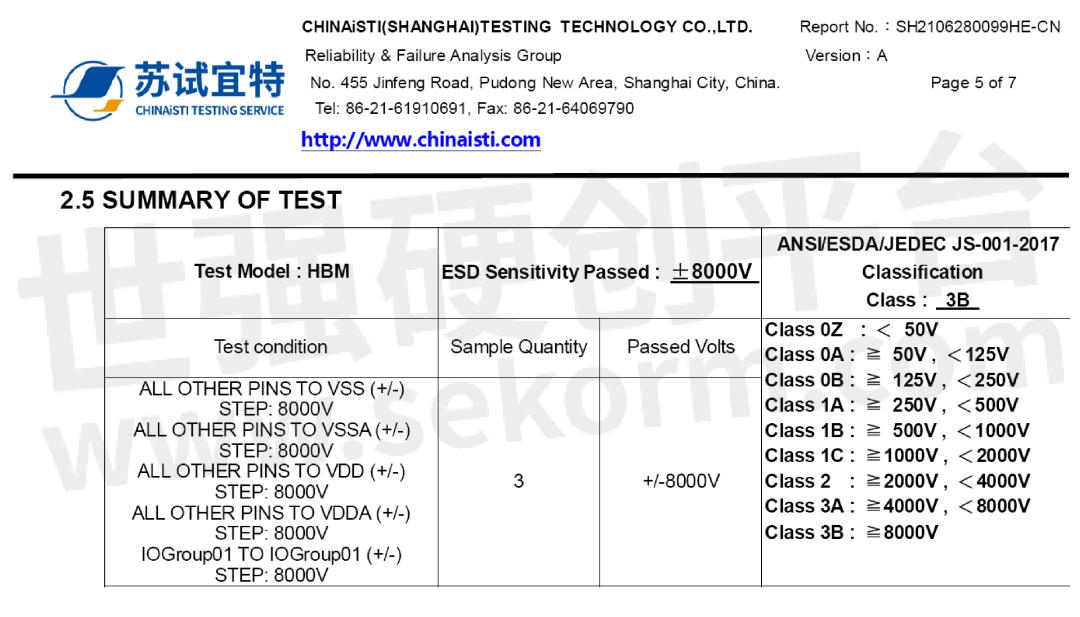

The interference in the welding industry site is too strong, so there are high requirements for the anti-interference of MCU. The reliability of all ESDs of Wuhan Core Source Semiconductor's MCU has reached the highest level of international standards, and HBM ESD has passed the 8KV test with strong anti-interference ability.

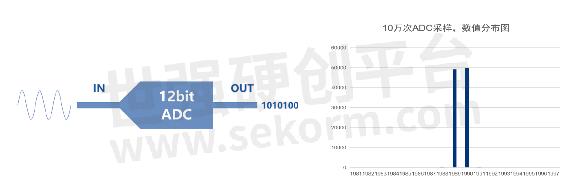

At the same time, the microcontroller monitors the welding process in real-time, requiring sampling and processing of parameters such as welding current and voltage, which requires extremely high ADC requirements for the microcontroller. The CW32F030 series MCU of Wuhan Core Source Semiconductor can achieve a high-precision ADC of 12 bits, with a range of ± 1.0 LSB INL and 11.3 ENOB (significant digits).

The application of single-chip microcontrollers in electric welding machines can not only achieve automated control, improve welding quality and efficiency, but also achieve energy-saving control and intelligent diagnosis functions. With the continuous progress of technology and the continuous development of application technology, the application of microcontrollers in electric welding machines will be more extensive and in-depth, bringing more convenience and benefits to industrial production.

- +1 Like

- Add to Favorites

Recommend

- CW32F030 Maximum Main Frequency 64MHz, is Used in Fascia Gun, Can Output an Instantaneous Strike Force of 130N

- Application of CW32F003F4P7 Series Products on Level Switches

- Application of CW32F030 in LED PWM Dimming Control Board

- CW32 is a Low-power 32-bit Microcontroller, Using Arm Cortex-m0+core, Very Suitable for Intelligent Temperature Controllers with Low Power Consumption Requirements

- Application of CW32L083 Series MCU in Air Purifiers, Supported by Built in Independent Calibration RTC

- The Application Solution of Wuhan Core Source Semiconductor CW32L083 in Intelligent Gas Meters

- CW32F030C8T6 MCU Supports an Ultra Wide Temperature Range of -40~105 ℃, Ensures Safe and Stable Operation of Portable Charging Gun

- Xinlian Innovation Adopted Wuhan Xinyuan Semiconductor‘s CW32F003 to Launch a Solution That Supports Wireless Charging of 15W and One Core Dual Charging

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.