Nidec Machine Tools Release “MVR-Cx“ :First Step Toward Expansion of Its Large-Scale Machine Tool Business

Nidec Machine Tool Corporation launched the MVR-Cx series of double-column machining centers as its first new product since becoming a subsidiary of Nidec Corporation on August 2.Nidec has set a goal of 100 billion yen in sales for the fiscal year ending March 2026 and will expand large machine tool business as a core business. The MVR-Cx series will be the first in its series.

The Nidec MVR-Cx series is a simple, easy-to-use machine that efficiently performs single-item and high-mix low-volume production in machining general large parts such as can structures. The newly developed "Nidec Navi" operation support function, which significantly reduces the production time from receiving a job to shipping a product, comes as a standard feature. A wide variety of original screens are available to simplify initial machining settings, such as program creation, debugging, and centering of the workpiece before machining, which used to be time-consuming in one-product and high-mix low-volume productions. In addition to the guidance to make the program easy to operate, a simple collision prevention function (opt.) is also available, making it easy to work with for those new to machine operation. Furthermore, 3D visual guidance is projected on the operation screen to support each operation until recovery when machine trouble occurs. This allows our support center to remotely access the machine at the customer's factory to monitor the machine status and provide prompt support based on the monitored information.

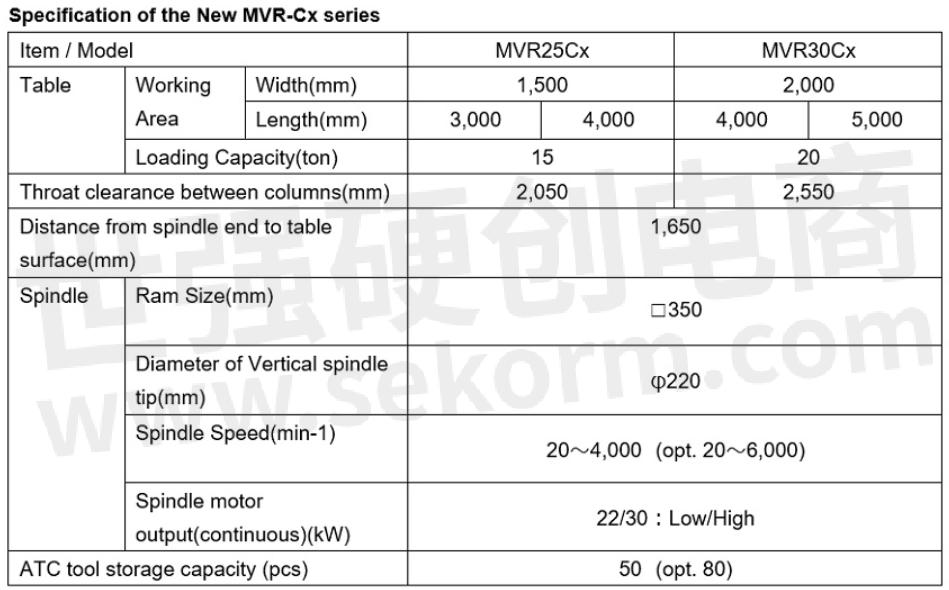

The maximum spindle speeds are 4,000 rpm and 6,000 rpm (Opt.), and the standard specification is a cylindrical attachment that can easily fit inside a can manufacturing structure. Grease is used as lubricant for the main spindle and attachments, greatly cutting energy costs by reducing air supply. Moreover, the assembly structure that can be installed in small or large locations and can be carried in by a 15-ton truck or installed in a narrow space.

Since its launch in 2003, the MVR series has been well received for its high accuracy and productivity, and has been delivered for a wide range of purposes such as molds, industrial machinery, construction machinery, and semiconductor manufacturing equipment, etc. The MVR-Cx quickly adapts to changes in the environment surrounding the manufacturing industry - it is a machine that is easy to operate even for those without experience which contributes to improvement in productivity.

With the launch of this new series, Nidec Machine Tools will not only continue to meet the needs of our existing customers for equipment renewal but also will engage in actively cultivating new users.

- +1 Like

- Add to Favorites

Recommend

- Nidec and Treedom Launch Environmental Training with 100 New Trees

- Nidec Instruments to Launch “S-FLAG DYNAMIC MOTION ™” MB Series AC Servo Motors

- Nidec Receives “Clarivate Top 100 Global Innovator 2024” Award

- Nidec Receives 2021 Bosch Global Supplier Award from Bosch Group

- Nidec Machine Tool Launches Easy-to-use New MVR-Aⅹ Series of Double-column Machining Centers to Meet Diverse Needs for Machining Large Components

- Nidec Industrial Solutions Evolves into a New Dimension: Nidec Conversion

- Nidec Machine Tool Develops Digital Twin Platform for Machine Tools

- Nidec Develops TapSense, the World’s Thinnest 1.4mm-thick Linear Resonant Actuator

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.