Nidec Machine Tool Develops Digital Twin Platform for Machine Tools

- The Company will exhibit MVR-Hx, a double-column five-face machining center with high desktop simulation and reproducing capabilities to contribute efficiency improvement and manpower reduction.

- The Company will propose new solutions to issues facing users.

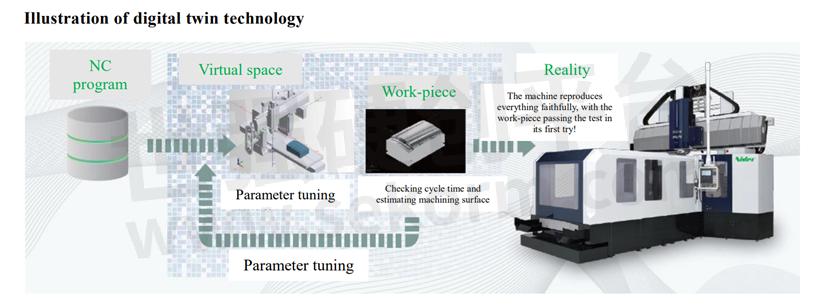

Nidec Machine Tool Corporation (“Nidec Machine Tool” or the “Company”) announced that it has developed a digital twin platform that, in a machining process using a large machine tool, reproduces an actual world highly accurately by using simulation. The platform performs verification and tuning in a virtual space to improve machining program’s data to the ultimate level of completion, and uses the Company’s machine tool that can reproduce data faithfully to speedily machine a work-piece at a target quality level. The digital platform will help reduce the number of actual equipment-based processes amid the metal-processing industry’s serious labor shortage caused by a declining workforce and people’s unwillingness to work in the manufacturing industry.

This technology analyzes processes in mental component machining works that consume a lot of operators’ time, and factors that reduce machine utilization. The newly developed application software uses digital technology and AI to solve such issues. This application software uses a virtual space (on a personal computer, or PC) to simulate a machining NC*1 program that was made to operate machines, to improve the degree of perfection to the ultimate level. This is why, at a factory, operators can obtain a deliverable of a target quality level only by starting the machining process, and without performing advance verification using the actual machine or a work-piece (a material to be processed).

Normally, prior to starting any machining process, a mechanical operator is required to check and set various machining conditions (e.g., movement interference, cutting load, and cycle time), and repeatedly correct those programs and perform a test-cutting procedure. Such debugging*2 processes take time, and the machine utilization remains low with the actual machine, resulting in a low productivity. By offering the application software, with which anyone can perform these works easily, the Company is ready to help improve productivity and reduce operators’ workload.

Specifically, the software program brings a PC- and monitor-based 3D image into a virtual space to check machines’ movements and work-pieces’ conditions accurately. This software enables an operator to check, among others, machining time, machined surfaces, and movements in a virtual space, without having to perform debugging or test-cutting with an actual machine. Furthermore, the Company’s highly reproducible double-column five-face machining centers can perform machining at a certain quality level without relying on people or places, enabling remote and multiple-place production.

*1. “NC” stands for “numerical control.”

*2. “Debugging” means to search for and specify the reasons for, and the source-code location of, any malfunction or defect discovered in a test after a programming glitch or mistake, to fix the malfunction/defect so that the program runs as intended.

*3. “FMII” stands for “fine mold,” which is the second generation of Nidec Machine Tool’s original mold-machining control functions.

- +1 Like

- Add to Favorites

Recommend

- Nidec Launched “MVR-Hx”Series of Double-Column Machining Centers to Accelerate The Expansion of Its Large-Scale Machine Tool Business

- Nidec Machine Tool Launches ZFA Series, Global-standard Gear Grinders that Meet the Global Needs for High-precision Gear Machining

- Nidec Develops AC Servo Motor Equipped with Zignear® , the Location Detection Technology that Accommodates 17-bit Resolution, for the Industrial Robot Market

- The Nidec Group’s Four Machine Tool Companies to Exhibit Products at CCMT2024 as Comprehensive Machine Tool Manufacturers to Meet All Industrial Fields’Needs

- Nidec Launches a Lineup of VR Series Servo Motor Reducers for Food Machinery, Achieving a Torque of up to 80% of Standard Models

- Nidec Industrial Solutions Evolves into a New Dimension: Nidec Conversion

- Nidec Receives 2021 Bosch Global Supplier Award from Bosch Group

- Nidec and Treedom Launch Environmental Training with 100 New Trees

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.