Inductor-Passive Components Usher in New Growth Opportunities in The Era of Electrification

In The Field Of New Energy, Power Inductors Play An Important Role

An inductor is a passive component that stores electrical energy in the form of magnetic flux. The inductor is an electromagnetic induction component, also known as coil, choke, etc., generally composed of a magnetic core and winding. The core performance mainly affects the maximum saturation current, core loss, and energy storage capacity, and the winding performance mainly affects the skin effect and proximity effect. As one of the three major passive components, the inductor is characterized by passing DC and blocking AC. It mainly plays the role of stabilizing current, screening signals, filtering noise, and suppressing electromagnetic interference. In the field of new energy, inductors are mainly power inductors used for specific voltage conversion, which alleviates current surges by temporarily converting electrical energy into magnetic energy and then releasing it back into the circuit.

Fig.1

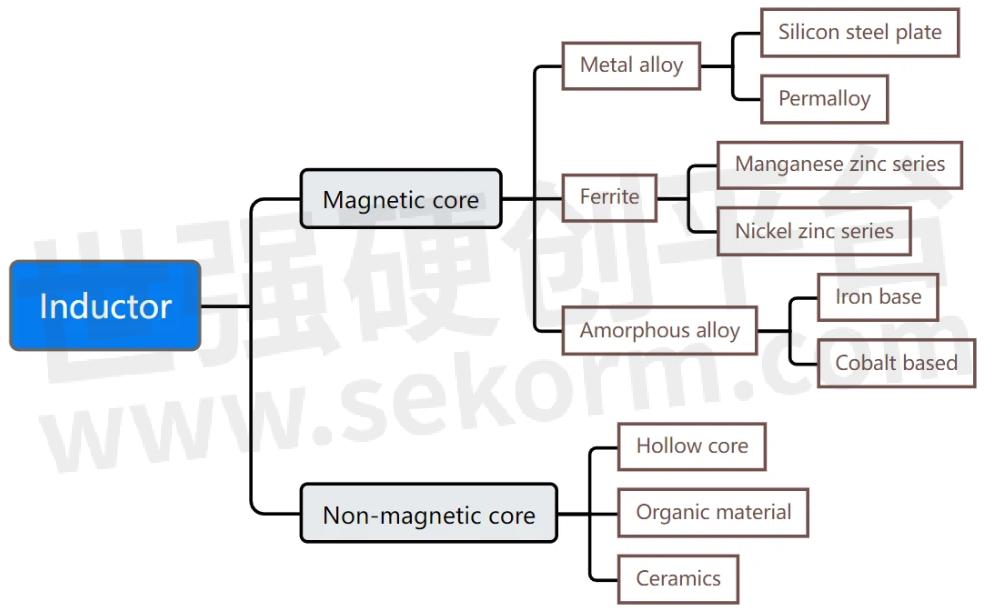

There are many types of inductors, which can be divided into multiple types based on winding structure, mounting form, and core material. Inductors can be divided into wire-wound inductors, laminated inductors, and film inductors according to the winding structure; according to the mounting form, they can be divided into lead-type inductors mounted by wave soldering and chip inductors mounted by reflow soldering; According to the core material, it can be divided into magnetic core materials and non-magnetic core materials. The core materials include metal alloy cores, ferrite cores, and amorphous alloy cores. The non-magnetic core materials include air cores, organic materials, and ceramics.

Fig.2

Fig.3

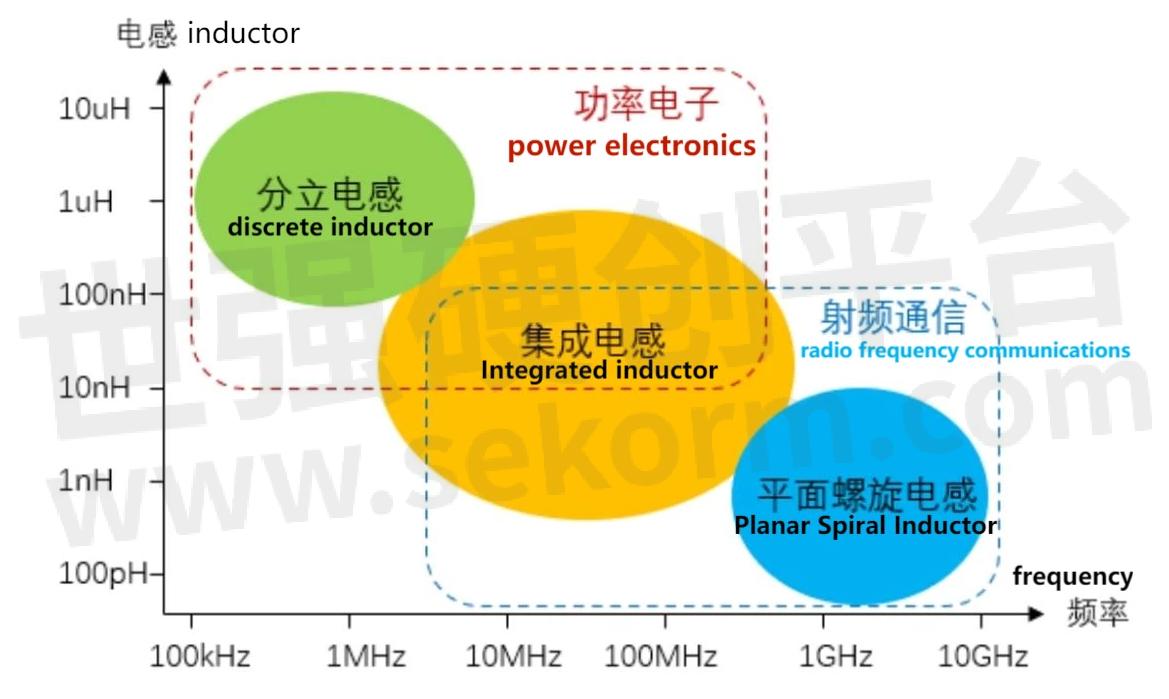

Depending on the downstream application, inductors can be divided into RF inductors and power inductors. RF inductors are mainly laminated inductors made of ceramic materials. They are mainly used in radio frequency communications. The application frequency ranges from a few MHz to tens of GHz. The main functions include coupling, which is generally used in antennas, IF, and other parts to eliminate detuned impedance and reduce reflections. Minimize losses; resonance, generally used in synthesizers and oscillation circuits; choke, generally used in RF and IF power lines to control high-frequency component currents. Power inductors are mainly wire-wound inductors made of ferrite materials. They are mainly used in power electronics. The application frequency range is below 10MHz. The main functions include voltage conversion, accumulation and release of current; and choke, generally used in DC-DC conversion circuits, to block the flow of high-frequency current.

Inductors show the development trend of miniaturization, high frequency, and high power. With the development of consumer electronics and Internet of Things equipment, under the trend of equipment miniaturization, improving the packaging integration of electronic components and miniaturizing inductors has become the main direction. With the rapid promotion of 5G applications, the communication frequency bands used by electronic products are getting higher and higher, and inductors need to develop in the direction of high frequency. With the rapid increase in the penetration rate of new energy vehicles, photovoltaics, and wind power, the demand for high-power components in the new energy industry has increased, and inductors need strong withstand voltage and current capabilities.

The properties of magnetic materials are different and their application fields complement each other. The performance advantages of metal magnetic powder cores are significant. Most of the magnetic cores in inductors are made of soft magnetic materials. Soft magnetic materials have experienced changes from traditional metal soft magnetic, ferrite soft magnetic, amorphous and nanocrystalline soft magnetic, and metal magnetic powder cores. Ferrite is the best choice for high-frequency applications, including four types: manganese-zinc series, nickel-zinc series, barium-zinc series, and magnesium-zinc series. It is mainly used in communications, switching power supplies, sensing, automotive DC-DC converters, EMI inductors, etc. Metal magnetic materials include metallic soft magnetic materials and amorphous soft magnetic alloys.

Metal soft magnets include silicon steel, silicon aluminum, permalloy, etc., which are mainly used in inductive components such as transformers, generators, and inverters. Amorphous soft magnetic alloys are divided into iron-based, iron-nickel-based, cobalt-based, nano-soft magnetic alloys, etc., and have a variety of application scenarios. Nanocrystals combine the advantages of ferrite and amorphous soft magnetic materials. They are the best choice in the field of high-frequency power electronics and can be used in consumer electronics, new energy vehicles, photovoltaics, and other fields.

Metal magnetic powder core combines the advantages of traditional metal soft magnets and ferrite soft magnets. It has comprehensive performance and is known as the "fourth generation" soft magnetic material. It meets the requirements of miniaturization, high power density, and high frequency of power electronics. It can be used in photovoltaic inverters, vehicle power supplies, switching power supplies, and other fields.

- +1 Like

- Add to Favorites

Recommend

- The Inductor Coil Manufacturer Briefly Describes the Performance Indicators of the Inductor Coil for You

- Nearly 90% of Electronic Transformer and Inductor Enterprises will Transform into Automated Production

- Do You Know the Structure of the Inductor?

- The Micro Inductor Supplier, Guangzhou Jinkai Electronics (CHK) and Sekorm Announced a Distribution Agreement

- Integrally Formed Inductor Recommended for TWS Earphones: XRTC252012S2R2MBCA from Xiangru Electronics Has a Low DC Resistance of Only 65mΩ

- Inductor and Transformer Testing Methods and Experience

- Xiangru Electronics Introduced an Integrated Inductor XR0630-4R7M, with a Maximum Dc Resistance of Only 42mω and a High Saturation Current of 7A

- New Era to Power Delivery: Sunlord Multiphase Co-Fired Power Inductor HTF-MP Series

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.