What is Air Gap Bonding?

Air gap bonding is an inexpensive and versatile display bonding technology.

As performance requirements for integrated touchscreens and displays continue to evolve, effectively bonding display components together is critical. A typical display is composed of many layers such as cover glass, a touchscreen, and/or an LCD that are all integrated to ensure the display functions optimally under its intended conditions. Boyd combines these separate components together using high-grade adhesives and unique bonding technologies.

As a front panel integrator, Boyd offers three main bonding technologies to help customers develop the ideal display construction and component stack-up: air gap (or framed adhesive), rigid-to-rigid liquid optically clear adhesive (LOCA), and optically clear adhesive (OCA) bonding. These bonding solutions serve a wide range of industries, including consumer, medical, military, automotive, instrumentation, and industrial controllers.

We discuss the benefits and challenges of each of these bonding technologies in this three-part blog series. To begin, we review one of the original display bonding capabilities at Boyd: air gap bonding.

What is the Process Behind Air Gap Bonding?

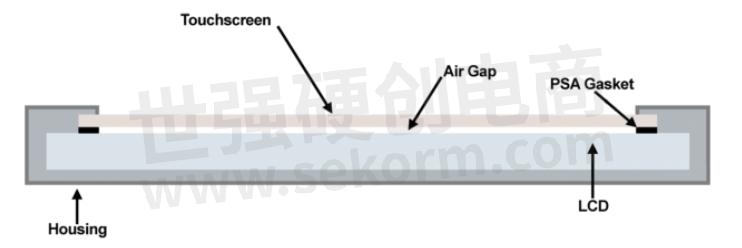

Air gap bonding uses a framed adhesive gasket around the perimeter of the display layers, leaving behind a small air gap within the stack-up. As there are no liquid adhesives to dispense and no cure time, air gap bonding is significantly less expensive than other bonding options.

Why Choose Air Gap Bonding?

Air gap constructions are cost-effective and lightweight, so they are popular solutions for applications with no readability or impact-resistance requirements.

While the lower cost is a benefit, this construction can present a few challenges. The air gap can affect screen clarity in bright light due to additional light refraction. Displays with air gaps are also more susceptible to moisture damage and breakage, so they are not ideal for outdoor applications or harsh environments.

Boyd has decades of experience creating custom display bonding technologies for the ideal stack-up in your display.

- +1 Like

- Add to Favorites

Recommend

- Flow Types in Aavid Genie: Ducted Versus Bypass Flow

- Sekorm Became an Official Authorized Distributor of Aavid

- Boyd Acquires Sensata’s Thermal Test and Controls Business

- AAVID Provides A Thermal Solution Optimizing Internal and External Thermal Radiation and Internal Conduction

- Aavid‘s Liquid Cooling Systems: Modular or fully customized liquid cooling optimized for improved heat dissipation in condensed volumes

- Boyd‘s New Art Facility in Mexico Features Automated Manufacturing and Assembly Processes

- Boyd Corporation Acquires ThermaMasters, Further Expanding Liquid Cooling Offerings

- An Industrial Grow Lamp Company Chose Boyd, to Design and Manufacture Their Hi-lumen Industrial Led Grow Lamp

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.