Flow Types in Aavid Genie: Ducted Versus Bypass Flow

Aavid Genie has a few different options when it comes to defining flow for your thermal simulation. Genie defaults to having ducted flow for all three flow types in the Flow Definition portion of a project. One flow type, standard fixed flow, has the option of adding bypass flow around your heat sink. For those of you new unfamiliar with these terms, we'll go through what ducted versus bypass flow versus free flow are and how you use them in Aavid Genie.

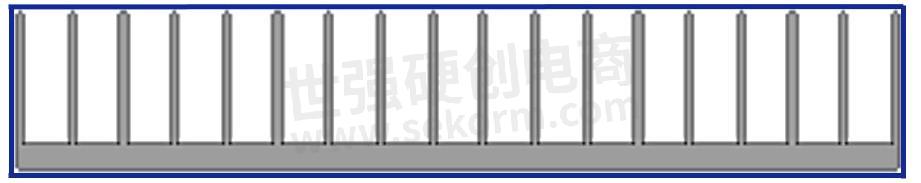

Ducted Flow

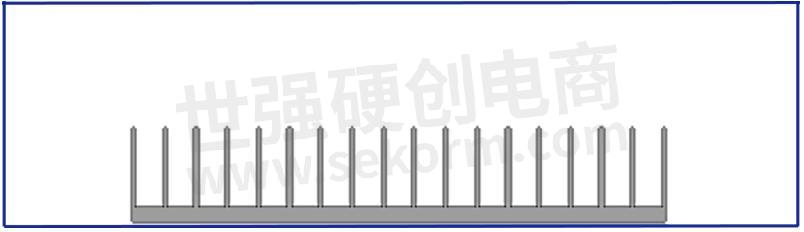

When fluid is fed through a sealed channel or duct that forces all the fluid through the fins of the heat sink, that flow is considered ducted. This is the flow type that Aavid Genie assumes as a default.

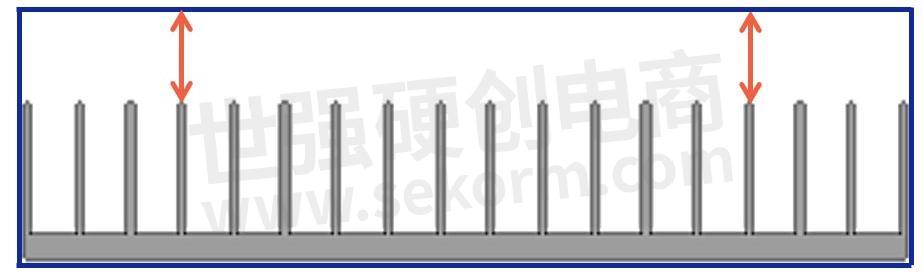

Bypass Flow

Bypass flow is a modification of ducted flow, where the walls of the sealed channel are not right up against the edges of the heat sink. This extra space between the heat sink and the channel walls allows the flow to bypass the fins, hence the name.

Typically we refer to vertical bypass as additional clearance added between the tip of the fins and the top of the duct. Fluid flow will be able to move more freely in the space above the fins.

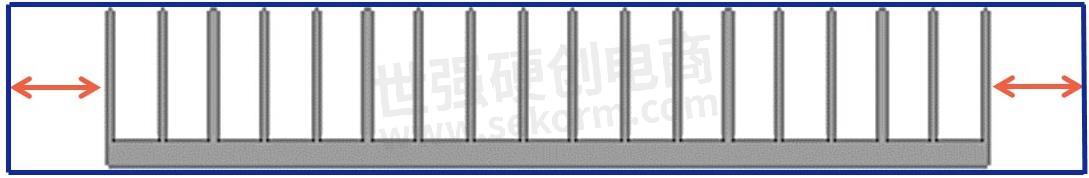

If we add clearance to the sides of the heat sink, that is considered horizontal clearance. If the width of the horizontal bypass is greater than the fin gap, fluid can travel more freely in the bypass than it can in between the fins.

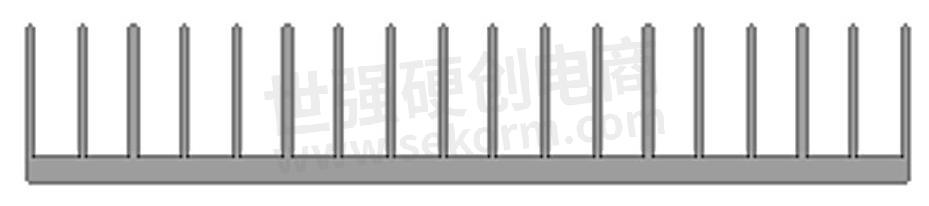

Ducted Versus Free Flow

The flow is considered "free flow" if the heat sink doesn't have a well defined duct or the duct is fairly far away from the edges of the heat sink. Free flow is common in natural convection applications, but there may be forced convection that may have a free flow situation. An example would be an enclosure that has a fan blowing air into the system, with grilles or perforation that allow air.

In most simulation software, there needs to be some sort of boundary in order to limit the amount of computation the program undergoes. Otherwise, you'll be asking you're computer to calculate more than you need it to. Aavid Genie is the same way. We have defaulted it to always have some level of ducting for any standard flow.

Mimicking Free Flow in Aavid Genie

You can mimic free flow in Aavid Genie by increasing both the vertical and horizontal bypass. By adding all this extra space, you reduce the influence of any boundary layers generated by the duct walls and let the flow acting on the heat sink be unhindered. Just make sure you use a flow velocity instead of a flow rate. Flow rate is volumetric, and by increasing your flow area, you're drastically cutting down on the actual velocity.

There you have it, ducted versus bypass flow. Try it out in Aavid Genie in the Flow Definition page of your project! Test out what works best for your custom heat sink design. If you need some assistance in determining the constraints of your flow, talk to experienced Aavid Design Engineers.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.