Heat Dissipation Application of Thermal Interface Material in PCB board

The internal temperature of electronic equipment rises, and the life of the PCB board in the electronic equipment will be shortened under a continuous high-temperature environment, and the system failure rate will increase under high temperature, which is prone to an abnormality at a certain key point, so the design of electronic equipment must consider heat dissipation.

As the support body of electronic components in electronic equipment, the PCB board is the carrier for the electrical interconnection of electronic components. The main body of electronic equipment heating is some electronic components of power consumption. Electronic components are assembled on a PCB board, and the waste heat generated by the heat source is very It is easy to accumulate and increase the temperature of the PCB board, which affects the operation of the system.

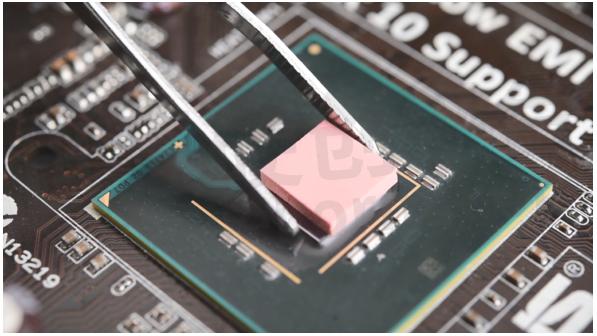

Heat dissipation devices such as heat dissipation fans, heat sinks, and heat pipes guide the heat from the surface of the heat source into the heat dissipation device, thereby reducing the temperature of the heat source. However, in thermal management, there are gaps between planes, and heat is conducted from the heat source to the heat sink. When cooling the device, it will be hindered and affect the speed, so a Thermal interface material will be used to fill the interface gap.

Thermal interface material is a general term for materials that are coated between heating devices and heat dissipation devices and reduce the thermal resistance of interface contact. There are many types of thermal interface materials, such as silicon-free thermal pads, thermal phase change sheets, thermal gels, thermal silicon Grease, carbon fiber thermal pad, thermal silica gel sheet, thermal phase change film, etc. The above-mentioned thermal interface materials are common in people's life and work. Some thermal interface materials have relatively complicated application environments, and the thermal interface materials used are also different. There are many heat sources on the PCB board, so there are many thermal interface materials used, and the application range is very wide.

- +1 Like

- Add to Favorites

Recommend

- Why Use a Thermal Interface Material with High Thermal Conductivity?

- Thermal Grizzly CPU Contact Frame Intel 1700 LT is Now Available

- Thermal Grizzly Product Update: AM5 High-Performance Heatspreader with New Nickel Plating

- Thermal Interface Material Supplier Offers High-Quality TIM Solutions

- Thermal Grizzly Prepared Four New Products for Intel’s Arrow Lake Processors

- New THERM-A-GAP GEL 75 Thermal Gel Offers High Thermal Conductivity and Reliability

- Parker Chomerics‘ THERM-A-GAP™ Gel 20 One-component Thermal Interface Material with 2.4W/m-k Thermal Conductivity Ideal for Automotive Industry Applications

- Why Does Thermal Resistance Affect the Thermal Conductivity of Thermal Silicone Pad?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.