Why Use Thermally Conductive Materials?

Electronic components are prone to failure at high temperatures, resulting in system freezes, and excessive temperature will reduce the service life of electronic products and accelerate the aging speed of products. The heat source in electronic products and machinery equipment is based on power consumption electronic components device-based, such as chips for mobile phones and CPUs for computers.

Air is a poor conductor of heat. After the equipment generates heat, the heat is not easy to dissipate and accumulates in the equipment, resulting in excessive local temperature and affecting the performance of the equipment. Therefore, people will install radiators or fins to reduce the excess heat source. The heat is channeled into the cooling device, thereby reducing the temperature inside the device.

There is a gap between the cooling device and the heating device, and the heat will be resisted by the air when it is conducted between the two. Therefore, the purpose of using a thermal interface material is to fill the gap between the two and remove the air in the gap, thereby reducing the heat dissipation of the heating device and the cooling device. Indirect contact thermal resistance, thereby increasing the rate of heat transfer.

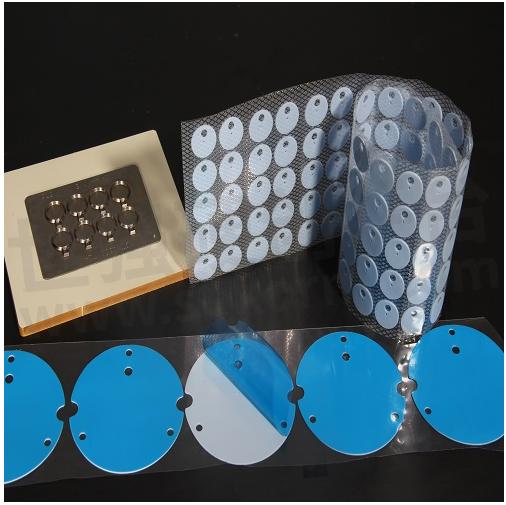

There are many types of thermally conductive materials, such as thermally conductive silicone sheet, thermally conductive gel, thermally conductive silicone cloth, thermally conductive phase change film, carbon fiber thermally conductive gasket, thermally conductive silicone grease, silicon-free thermally conductive gasket, etc. The types and styles of electronic products and machinery equipment are different. In different situations, suitable thermally conductive materials can be selected according to the heat dissipation requirements to make them effective.

- +1 Like

- Add to Favorites

Recommend

- A Brief Description of Thermally Conductive Materials - Thermally Conductive Gel

- Thermally Conductive Materials with Ultra-high Thermal Conductivity

- A Brief Description of Thermally Conductive Materials - Carbon Fiber Thermal Pads

- Why Use Thermally Conductive Insulating Sheet?

- Thermal Grizzly CPU Contact Frame Intel 1700 LT is Now Available

- What is a thermally conductive silicone sheet?

- Heat Dissipation Requirements of Electronic Components and Application of Thermally Conductive Materials

- Thermal Grizzly Product Update: AM5 High-Performance Heatspreader with New Nickel Plating

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.