Q&As for Acoustic Component Design

People are spending more time at home during the COVID-19 pandemic and it causes a boost in demand for related products, such as wearables, notebooks, video conferencing equipment, smart speaker, etc. They all have one thing in common: speakers and microphones are key components for audio and communications.

Fig.1

Q: How to design a slimmer speaker for a device that doesn’t have enough room?

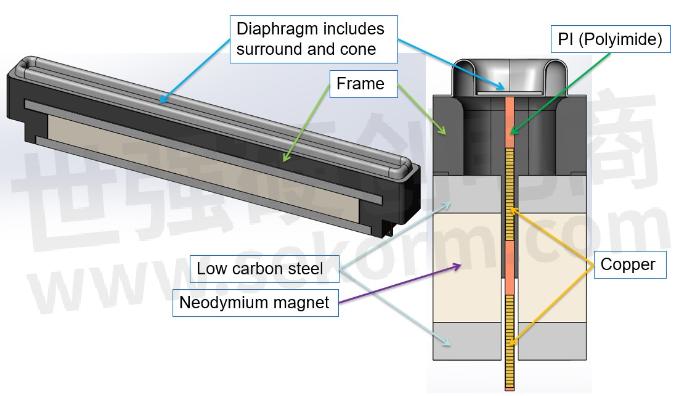

A: Take a notebook (or touch panel) for example Most speakers designed for a notebook or combined under a slim surface, need to be narrowed the heights down. Instead, the length and width of the speaker have to be extended to ensure SPL performance. However, it usually requires two and multiple motors (voice coils) and they also make the cost higher. There is a solution: We can have the voice coil made by FPC (Flexible Printed Circuit) which has fewer limitations on the length and width of speakers. The FPC voice coil speaker should be designed with a proper magnetic circuit and structure, it’s easy to develop relatively longer and slimmer speakers in rectangular shapes.

Fig.2 The FPC voice coil speaker

Fig.3 Simulated frequency response of the FPC voice coil speaker with a 5cc closed box at 1 watt and 0.5 meters (Speaker: L50mm*W4.5mm*H12mm)

Q: How to design microphones near speakers without causing howling or echo?

A: Here are some tips:

1. Mic Array: Mic Array is formed by 2 to 8 pcs of microphones and combined with DSP & Beamforming algorithm; it could achieve Voice Far Pickup & Noise reduction to improve the quality of voice call.

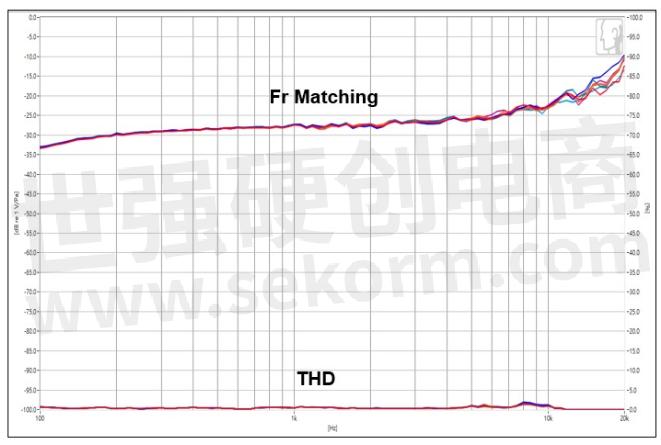

2. Mic Sensitivity & Frequency: The sensitivity of each microphone of Mic Array should be close to the Fr, ideally is ±1dB, which can reduce the deviation of DSP during calculation, and the total length of the sound tunnel structure should not exceed 5mm and avoid the resonance frequency of the microphone channel <12KHz.

Fig.4 Microphone frequency response matching

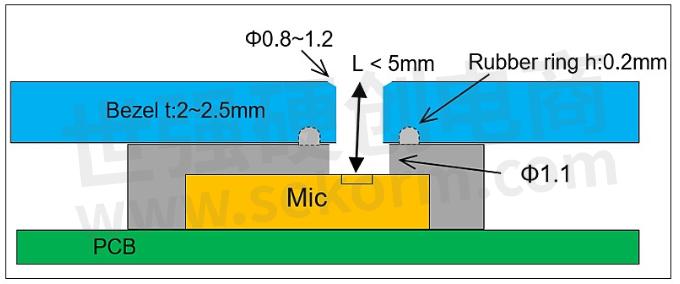

Fig.5 Microphone rubber holder and bezel

3. Mic Phase: Every Mic phase should be closer to each other will be better, ideally is ±5∘, which could reduce the time of deviation when DSP is working on calculation and ensure the accuracy of Beam & Directivity.

4. Mic Rubber Holder Sealing: The microphone rubber holder and Bezel must be seamlessly sealed, and the sound insulation must be at least 20dBSPL to prevent the sound of the internal speaker from entering the microphone's sound tunnel through the rubber gap.

5. Mic vs Speaker location and shock-proof: Considering the speaker amplification and microphone's AEC signal processing, usually we will put the speaker placed in the middle, and the microphone should be placed far away from the speaker, the microphone also needs to use the rubber for shock-proof and airtightness. The housing and the screw holes of the speaker should be secured by a sponge or rubber holder to avoid vibration, otherwise, the microphone will receive the THD signal from the speaker to affect the quality of the AEC.

- +1 Like

- Add to Favorites

Recommend

- Kingstate Signs an Authorized Distributor Agreement with Sekorm

- New Mic Modules Suitable for Automotive Smart Voice Systems

- Compact High-Sound Pressure Buzzers for IoT & Alarm Systems

- Tips for How to Design The Duplex Hands-free Calling Products of The Microphone

- Buzzers with Higher SPL and Smaller Cavity Based on 43-year Experience in Developing Acoustic Components,

- Kingstate, the world‘s leading electroacoustic component brand,signed the distributor agreement with Sekorm

- The world‘s top suppliers of connectors and structural parts: PhoenixContact, TE Connectivity, Weidmueller, etc.

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.