The Application of Copper Tubes and Its Importance

Nowadays, copper tubes have been used in electronic industries such as household appliances, water heaters, solar energy, automobiles, etc., and the demand is also increasing, which also makes the sales volume of copper tubes become better and better. Then, what is the specific performance of copper tubes in the application field of water cooling plates? Please follow the article to analyze the structure and design field of copper tubes.

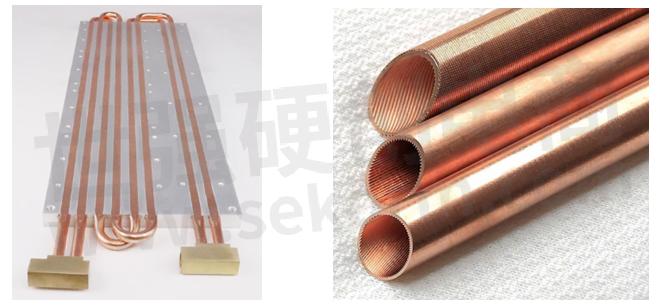

Application of water-cooled copper tube:

Most of our copper tubes are used on water-cooled panels, because they are durable and have better heat transfer stability, and can be more perfectly used on aluminum water-cooled panels to transfer cooling liquid, which provides better decisive conditions for heat dissipation function Equipped with water-cooled panels, it also solves the problem of a large amount of heat accumulation for many high-power thermal resistance machines.

The diameter range of copper tubes used in water cooling panels is usually φ 6-φ 35mm, and the wall thickness is 0.5-3.0mm (except for special cases). The size of copper tubes depends on the flow rate of water, and the flow rate increases with the raise of the diameter of copper tubes. However, too thick copper tubes are not suitable for bending, such as R12 camber, and can only be greater than a small degree of curvature above R12. In comparison, for example, the thickness of air-conditioning copper tubes is generally 2 minutes, 3 minutes 0.5mm thick, 4 minutes 0.6mm thick, 5 minutes and 6 minutes 0.7mm thick; The angle can be R22, and the pressure is controlled at 0.98MPa.

Characteristics of copper tubes-strong thermal conductivity, more suitable for absorbing and evaporating heat.

Advantages-Good stability, better toughness and longer service life.

Importance of copper tube

Copper tubes not only play an important role in the liquid-cooled plate, but also play an irreplaceable role in the heat pipe. For example, the raw materials of the heat pipe are only copper tubes before processing. However, following the processing procedure, after filling copper powder and sintering with the inner wall mold, the copper tubes can also be made into sintered, grooved and wire mesh screen structures, which provide innate conditions for the high conduction of the radiator. In addition, the copper tubes also have the characteristics of conducting heat, which can quickly transfer heat and evenly distribute it on the inner wall side of each copper tube, this is the function that aluminum plate has no related to.

Yythermal has its own copper tube bender which can help customers to make the desired shape, and make the whole process of water cooling plate processing, including copper tube bending, pressure tube welding and final CNC automatic processing. Welcome the discussion and information from competitors and customers.

- +1 Like

- Add to Favorites

Recommend

- Copper Is Here to Stay in Power Electronics

- 4 Key Factors on Copper Plating

- WAYON High Current Gas Discharge Tubes Features Low Capacitance and Wide Voltage Range, Boosting Circuit Safety Protection

- Eaton authorizes Sekorm to distribute inductors, fuses, TVS tubes, super capacitors, power modules and other products

- Unlocking the Technological Charm of High-Speed Blower Tubes: HXY Power Device Optimization Solutions

- The Rise in Copper Prices And Its Impact on Electronic Component Costs

- The Sound of MOS Tubes Constantly Rising

- The YYthermal Cooling Heat Sink as The Role for Cooling of 5G Communication Facilities

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.