Application of NGI Battery Simulator in Smart Wearable Device Testing

With the continuous development and integration of mobile communications, image technology, artificial intelligence, and other technologies, more and more artificial intelligence products have entered the life of the public. Smart wearable devices are rapidly spreading and are widely used in various fields such as healthcare, navigation, social networking, business, and media, and can bring new experiences to life through different scenarios.

A smart wearable device is a hardware terminal that combines multimedia, sensing, identification, wireless communication, cloud services, and other technologies with daily wear to realize user interaction, live entertainment, health monitoring, and other functions. There are smartwatches, smart bracelets, smart glasses, smart clothing, and so on in our common life. Whether we use smart wearable devices to track steps or record sleep time, we all hope that the devices we use are accurate and reliable. Therefore, in order to ensure the reliability and accuracy of the device, smart wearable devices must be completed with strict and comprehensive tests before delivery.

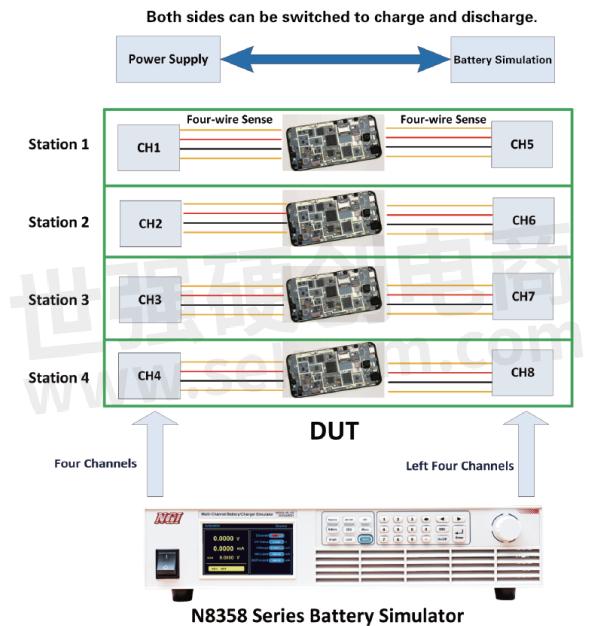

Fig.1

If a real battery is used for testing and research, battery purchasing and maintenance cost a lot. Furthermore, for experiments under extreme conditions, the batteries are often damaged, which slows down the research progress. Therefore, using a battery simulator to replace a real battery can reduce costs, speed up the project progress, and reduce the inconvenience of operation and use. NGI N8358 series high-accuracy programmable battery simulators have multiple test functions, such as source mode, charge mode, battery simulation, SOC test, etc., which are completely suitable for battery-powered smart wearable device tests.

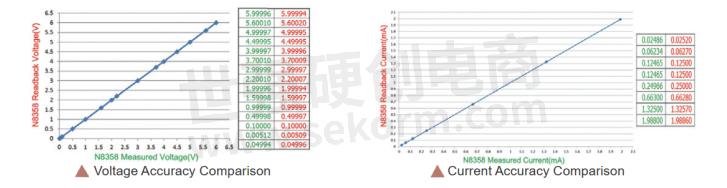

Fig.2

Thinness, tininess, and lightness are the basic requirements for smart wearable devices. Therefore, the battery life of wearable devices has become a key factor in gaining market share. The current accuracy of the NGI N8358 series battery simulator is as high as 1μA. Engineers can use the N8358 battery simulator to simulate the output characteristics of batteries, can intuitively test the small current in a standby state, and analyze the standby power consumption of the wearable device.

Fig.3

N8358 series battery simulators have bidirectional current, with SOC test and internal resistance simulation functions, which can be used to simulate changes in battery capacity and judge the working status of smart wearable devices. At the same time, N8358's fast dynamic response time of 10ms allows N8358 to switch quickly and continuously between the output current and the input current, which can effectively avoid voltage or current overshoot and is very suitable for smart wearable device testing.

N8358 series battery simulator also has fault simulation, DVM, and current auto-ranging functions. N8358 can provide repeatable test results. In the event of a failure in the test, N8358 can reproduce the failure, which can ensure the performance safety of the smart wearable device.

N8358 series battery simulator integrates 8 independent output channels in a 19-inch 2U chassis. Each channel can be flexibly controlled to realize the PCB jigsaw loading test, which greatly improves the test efficiency.

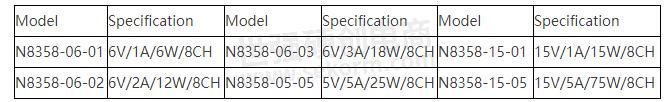

Quick Selection

Table.1

- +1 Like

- Add to Favorites

Recommend

- NGI N8358 High-accuracy Eight-channel Programmable Battery Simulator Application in BMS Test with High Current Accuracy up to 1μA

- Application of NGI Battery Simulator N8358 and N8352 in UAV Battery Management System Test

- NGI Lanuched N62100 Benchtop Lab Programmable DC Electronic Load with the Actual Measurement Rise of 5A/μs

- Application of NGI DC Power Supply in Hall Current Sensor

- The Advantages and Applications of Battery Simulator

- NGI Battery Simulator N8352 Series Application in Cell Phone Battery Supporting Current flowing in Both Directions

- Battery Simulator Application in Cell Voltage Monitor Calibration

- Application of Friction Stir Welding Technology in Battery Tray Manufacturing

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.