Battery Simulator Application in Cell Voltage Monitor Calibration

The fuel cell voltage monitor (CVM) is an important part of the fuel cell eNGIne system and stack inspection. It has the characteristics of multiple channels, fast response, and high voltage measurement accuracy. It can perform real-time analysis of the monitored voltage data group, comprehensive and rapid fault diagnosis, and real-time monitoring, diagnosis, storage, and query of the status and performance of the fuel cell stack monolithic, which can ensure the stability and reliability of the fuel cell, and improve the working efficiency of the fuel cell.

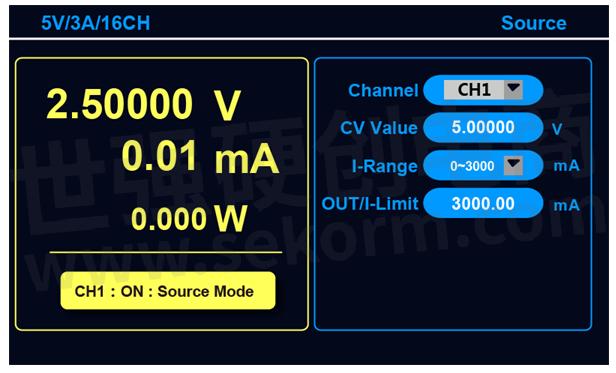

Fig.1

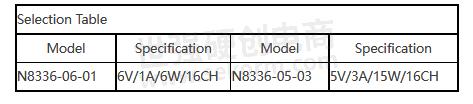

When engineers develop a CVM or do a CVM ex-factory test, in order to ensure the accuracy of CVM measurement, usually multiple power supplies are used for the CVM calibration test. Compared with the power supply, the Battery Simulator has the advantages of higher accuracy and more channels. A battery simulator has 16 tracks, which can significantly save the purchase cost of multiple power supplies. Therefore, engineers can use the battery simulator to complete the CVM calibration test. In response to users’ needs, NGI has developed the N8336 series 16-channel battery simulator. This battery simulator has the following characteristics.

Fig.2

Ultra-high integration for improving test efficiency

N8336 series standalone integrates up to 16 power supply channels which can be connected in series. Each channel is isolated. Ultra-high integration can greatly reduce the number of power supplies used in tests and improve the efficiency of calibration tests.

Ultra-high precision and high sampling rate

The voltage accuracy of the N8336 series battery simulator can reach up to 0.1mV. Its sampling speed can reach up to 10ms. These two features can meet the demand for DC power supply in the CVM calibration test.

Fig.3

Stable current output and programming function

N8336 series battery simulator can provide stable current output for CVM calibration test. Engineers can set the voltage and current of each channel separately on the application software. According to the test requirements, engineers can change the parameters at any time to fully simulate the output characteristics of the fuel cell and quickly verify the CVM response under different conditions.

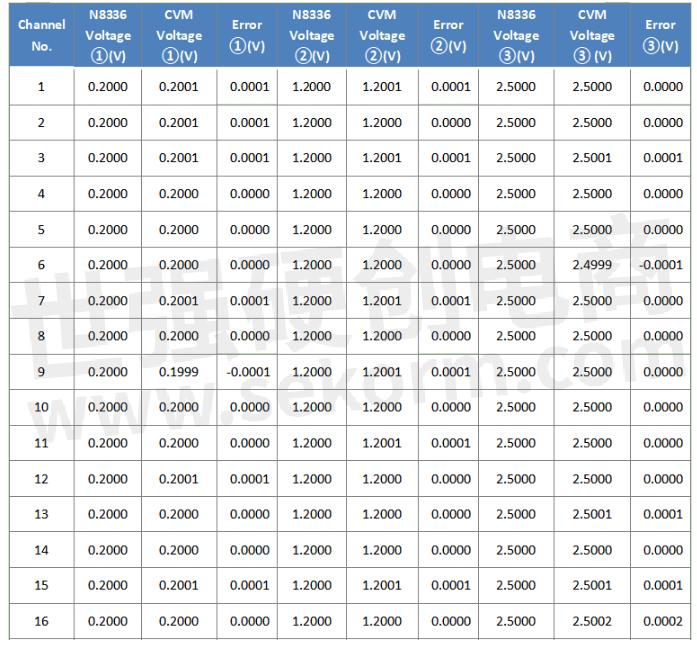

The below table is the test data of the N8336 battery simulator.

Table.1

Table.2

- +1 Like

- Add to Favorites

Recommend

- Application of NGI Battery Simulator in Smart Wearable Device Testing

- Application of NGI Battery Simulator N8358 and N8352 in UAV Battery Management System Test

- NGI Lanuched N62100 Benchtop Lab Programmable DC Electronic Load with the Actual Measurement Rise of 5A/μs

- Application of NGI DC Power Supply in Hall Current Sensor

- NGI N8358 High-accuracy Eight-channel Programmable Battery Simulator Application in BMS Test with High Current Accuracy up to 1μA

- NGI Battery Simulator N8352 Series Application in Cell Phone Battery Supporting Current flowing in Both Directions

- The Advantages and Applications of Battery Simulator

- Application of Friction Stir Welding Technology in Battery Tray Manufacturing

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.