Application of NGI Battery Simulator N8358 and N8352 in UAV Battery Management System Test

With the gradual maturity of drone R&D technology, drones have attracted attention from all walks of life for their low-altitude flight, low cost, flexible maneuverability, and rapid response. They are widely used in civilian fields, such as agricultural plant protection, power inspections, and police enforcement, geological prospecting, environmental monitoring, forest fire prevention, film and television aerial photography, etc. However, with the rapid development of the UAV market, constraints such as limited battery life have gradually become prominent. In this case, power management chip technology has become one of the key factors affecting the quality of drones.

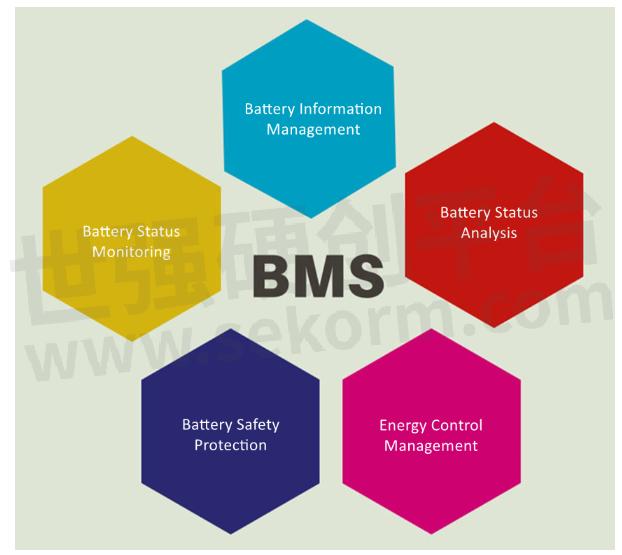

Most drones on the market are powered by lithium batteries. During charging or discharging, the drone battery may explode or catch fire, which is one of the shortcomings of polymer lithium battery technology. The battery management system (BMS) can solve key issues such as the safety, availability, and service life of the lithium battery system. It can be used to monitor and manage the battery, send an audible and visual alarm signal to the user under abnormal conditions, and cut off the power transmission according to a preset control strategy in severe cases to protect the battery and extend the battery life. To ensure product quality and battery safety, manufacturers usually need to equip the battery with a BMS and conduct a comprehensive test on the BMS before leaving the factory.

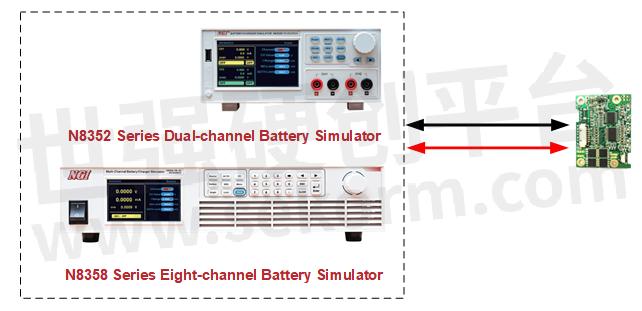

To meet the needs of BMS test applications, NGI has developed N8358 series and N8352 series high-precision dual-quadrant programmable Battery Simulators. N8358 and N8352 can simulate the output state and charge&discharge characteristics of real batteries and can change the test conditions at any time according to the needs of users, achieving the purpose of quickly verifying the response of UAV battery management system under different battery conditions.

Test Items:

Battery cell voltage acquisition accuracy test

Battery protection parameter test

Static power consumption test of BMS acquisition circuit

Battery balancing test

Battery fault simulation

Test Advantages:

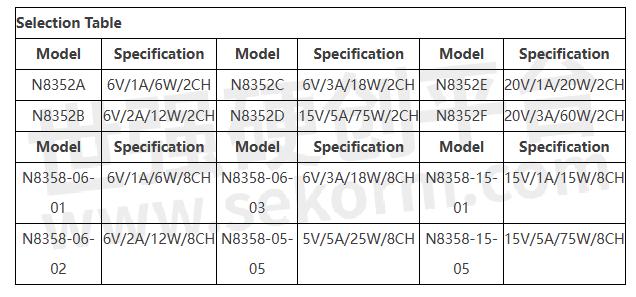

1. Generally, drone design will take weight and endurance into consideration to select the appropriate number of battery cells. Small UAVs have fewer battery cells than large UAVs, so the requirements for testing UAV battery management systems are also different. N8358 battery simulator integrates 8 independent output channels. N8352 battery simulator integrates 2 independent output channels. Engineers can select the battery simulator with the corresponding number of channels according to different UAV battery management systems test to meet the needs.

2. When the drone is not in use, the drone will be in a standby state. There is still a leakage current in the standby state. In order to detect the leakage current (standby power consumption), the current accuracy of the test instrument needs to reach μA level. Both N8358 and N8352 battery simulators have 1μA current accuracy. N8358 and N8352 can intuitively test the standby power consumption of the UAV battery management system in the standby state, which fully meets the UAV BMS test requirements.

3. Both N8358 and N8352 adopt current bidirectional design. The current input and output direction can be independently controlled by each channel, which meets the requirements of the UAV BMS active and passive balancing test.

4. The channels of N8358 and N8352 are isolated from each other and support multi-channel series connection. When testing BMS of small UAVs, N8352, and N8358 can be used in series connection to simulate the total voltage signal of BMS. This method can replace the power supply which is used to simulate the total voltage of BMS and save test costs.

5. N8358 and N8352 battery simulators also have SOC tests, fault simulations, internal resistance simulation, and current auto range functions, which can efficiently meet the needs of UAV BMS testing.

- +1 Like

- Add to Favorites

Recommend

- NGI N8358 High-accuracy Eight-channel Programmable Battery Simulator Application in BMS Test with High Current Accuracy up to 1μA

- Application of NGI Battery Simulator in Smart Wearable Device Testing

- NGI Lanuched N62100 Benchtop Lab Programmable DC Electronic Load with the Actual Measurement Rise of 5A/μs

- Application of NGI DC Power Supply in Hall Current Sensor

- The Advantages and Applications of Battery Simulator

- NGI Battery Simulator N8352 Series Application in Cell Phone Battery Supporting Current flowing in Both Directions

- Battery Simulator Application in Cell Voltage Monitor Calibration

- Application of Friction Stir Welding Technology in Battery Tray Manufacturing

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.