How to Apply Low-cost Single-point LiDARs for Coal-flow Volume Measurement

As one of the country's main sources of conventional energy, coal is also an important pillar of the country's economy. According to statistics, China's annual coal output reached more than 3 billion tons. In traditional coal transportation, the detection tools are worn out, unstable, and cannot accurately detect all kinds of data. In order to improve the management efficiency of coal companies, real-time monitoring of coal production and transportation is required to provide reliable data support for the coal management and operation system. BENEWAKE has launched a special module: "Low-cost single-point LiDARs coal-flow volume detection system", this system can realize the real-time monitoring and statistics of the volume of coal transported by the conveyor belt during coal loading and coal pile transportation.

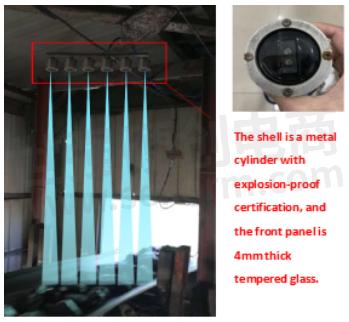

Figure 1: System architecture diagram

Install multiple LiDARs of the system above the conveyor belt. According to the coal height change curve, actual belt speed and coal flow cross-sectional area obtained by the LiDAR during the operation of the conveyor belt. The dispersion per unit time is calculated through the calculation within the system. The coal volume can be calculated according to the coal volume coefficient per unit volume at the same time.

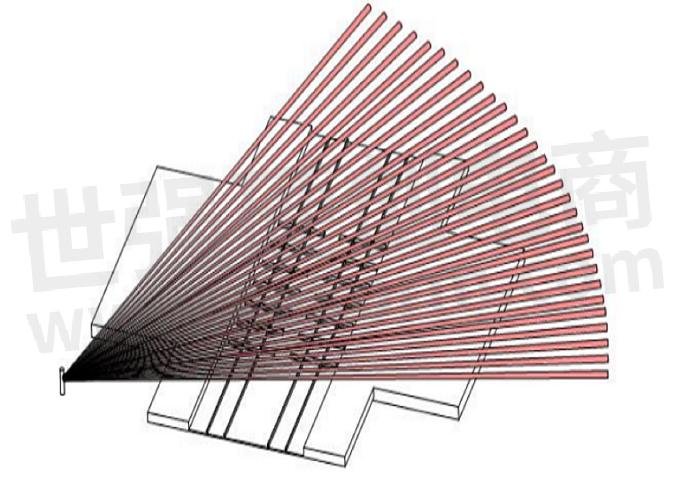

Figure 2: System architecture diagram

The system components are mainly composed of 6~8 TFmini-S single-point LiDARs (the number of LiDARs can be adjusted according to the size of the conveyor belt and the detection range calculated by the height of the installation system) with Modbus RS485 communication interface, 1 controller, N meter length composition. The whole system uses a 12V power supply. This system is a low-cost single-point LiDARs coal flow volume detection system. Customers can choose other products, such as TFmini-Plus, TF-Luna, etc. according to the requirements of measuring height.

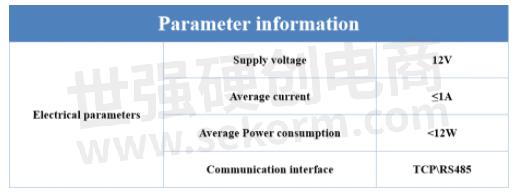

The calculated kernel is the main algorithm of the carrying system, the main parameters are as follows:

Table.1 Parameter information

Figure 3: Test connection diagram

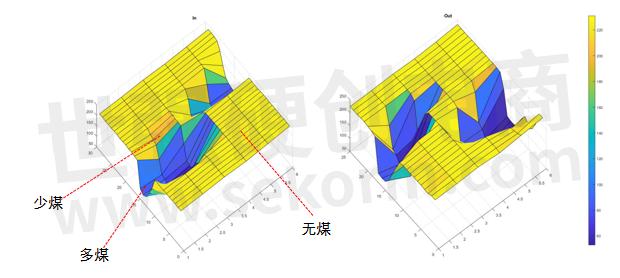

Figure 4: From left to right is the raw data (1: ID number, 2: ranging value) after multiple LiDARs are connected, and the change curve of coal height when there is no load, small amount, and large amount

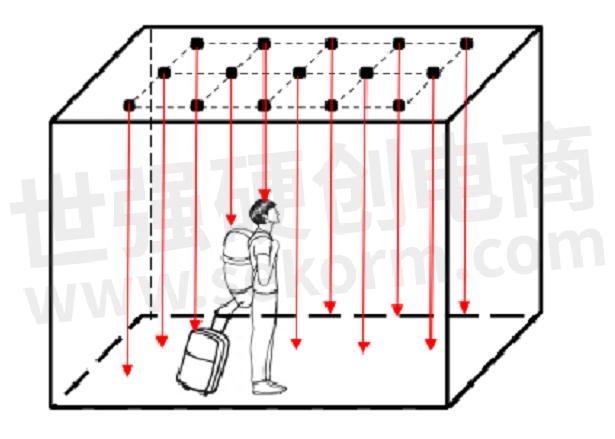

Figure 5: Top view rendering

From the test results, the range accuracy of multiple LiDARs to coal fluctuates at the cm level, which satisfies the measurement standards of coal pile volume and the calculation of coal quantity.

Solution Advantage

1. Non-contact detection, no wear, and long life;

2. The frequency range is up to 1000 Hz, which can detect coal flow data in real-time with high accuracy;

3. Convenient installation and easy realization;

4. The cost of multiple single-point LiDARs is low in networking mode. The overall system is distributed, which means if one of the LiDARs becomes faulty, the rest of the system is not affected, and the data is still stable;

Through this low-cost single-point LiDARs coal flow volume detection program, customers can obtain accurate coal flow volume data, improve work efficiency, improve energy conservation awareness and reduce production costs.

Scalable Scenarios

1. Elevator space occupation detection/People flow detection

Use TFmini-S/TF-Luna as a 3×5 (adjustable according to the size of the elevator space) networking light array, installed on the top of the elevator inner side. The system checks with LiDARs array whether the elevator interior space is full, if it is full, the elevator will not stop at any intermediate floor that comes before the destined floor. This kind of application is suitable for high-rise buildings.

Figure 6: Simulation diagram of elevator space occupancy detection

2. Abnormal object detection

For railway and highway level crossings, a monitoring system is designed and built to monitor the presence of objects (mainly people and vehicles) in the crossing in real-time. If there are pedestrians or vehicles passing by, the distance measurement information of the LiDARs will give a warning prompt.

Figure 7: Simulation diagram of foreign body detection

- +1 Like

- Add to Favorites

Recommend

- Benewake Offers A Low Cost Solution for Aunattended ETC Quick Toll Collection

- Benewake‘s TF Series Single-point LiDAR Designed for Forks Obstacle Avoidance

- Benewake‘s LiDAR Used in Intelligent Roadside Parking, Supporting Black Car Ultra-distance Detection

- Based on TOF, Benewake‘s Lidar Can Be Integrated into the Robot and And Realize Obstacle Avoidance

- Benewake LiDAR Sensors Improve Vehicle Mobility and Overcomes Parking Problem in Three-dimensional Parking

- TFSeries Lidar That Can Be Used as Fall Detection Sensor of the Robot

- Benewake and Jabil Sign Strategic Cooperation Agreement to Accelerate the Mass Production of Automotive-grade LiDAR and Empower Intelligent Driving Safety

- Benewake Long Range Single-point LiDAR Used for Vehicle Crash Warning with Long Warning Range of 350m

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.