How to Mount Board to Board Connectors?

What are the ways to mount BTB Connectors?

Board-to-board (BTB) connectors are used to accurately interconnect printed circuit boards (PCBs) in a stackable manner. They can accommodate various types of PCB orientations, relative distances, and space constraints to allow design flexibility. In addition, multiple materials, plating finishes, and pitches are available to meet electrical and mechanical specifications. Depending on the purpose of the interconnection, connectors are featured further, such as high-speed, floating, or power. To achieve the desired performance, all the above should be considered to design a suitable interconnect system.

What are the types of Board to Board Connectors?

Pin headers & Female headers:

Pin headers (male) and female headers (socket) are used as a set. They are separately installed on the PCBs. This allows these PCBs to be easily connected to complete the design or disconnected for replacement if any of them got damaged.

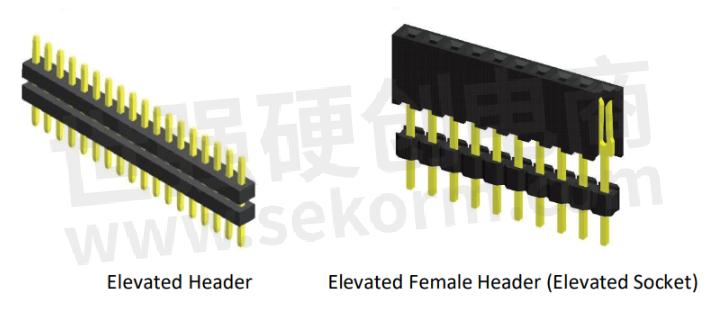

Elevated headers:

Elevated headers and female headers are constructed with extra plastic holders in place. This offers great control of the mating height when the distance must be precisely kept between the PCBs.

Box Header connectors:

Box Header is featured plastic shrouded around the header. This helps to guide the connectors during the mating process to avoid incorrect mating attempts.

Polarized Connectors:

Polarized connectors are engineered with self-aligning features to allow mating only in a specific way. This eliminates the risk of misalignment especially when the connectors are not in a visible position, or blind mated.

Edge connectors:

Edge connectors are designed to be exceptionally robust and durable for the frequent mating process. They are commonly used in personal computers for connecting expansion cards and computer memory to the system bus.

Floating connectors:

Floating connectors are uniquely designed to equip with spring-like terminals. With automation widely applied to manufacturing, the connectors can absorb the alignment errors from pick-and-place machines. Additionally, the spring-like terminals also reduce the stress on connectors from vibration.

- +1 Like

- Add to Favorites

Recommend

- What is Board To Board Connectors?

- How to Check the Board to Board Connector of Mobile Phone?

- ept One27® SMT PCB Connectors with a Pitch of 1.27mm is Suitable for Board-to-board Applications ∣ video

- How to Select the Right Board to Board Connector?

- How to Select Board-to-board Connectors?

- Function and Parameter Selection of Board-to-Board Connectors

- Features and Classifications of Board-to-Board Connectors

- Greenconn荣获邓白氏企业认证,实力彰显行业领先水平

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.