An overview of Power battery heat dissipation

Vehicle and battery energy storage, gain a rapid development opportunity.

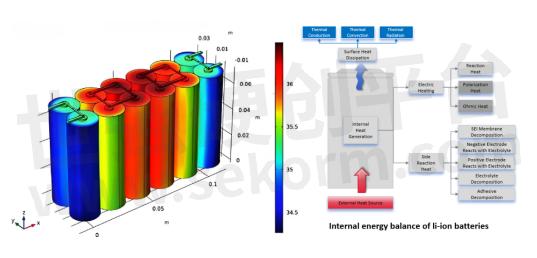

And its core component, the power batteries belong to chemical power sources, and they are highly sensitive to temperature, require working in a suitable temperature environment. During the charging and discharging process of power batteries, a large amount of heat is generated due to the internal impedance. Further more, the battery pack is in a relatively enclosed environment. It’s convenient for heat accumulating, arising the temperature , even cause thermal runaway to happen. Therefore, an efficient and safe power battery cooling system has become particularly important.

Currently,there are three battery cooling schemes, respectively as air-cooled, Liquid cooling, direct refrigerant cooling.

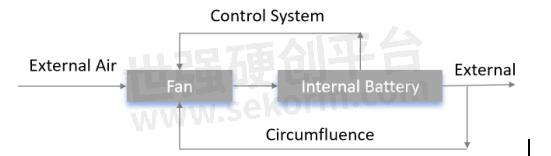

The structure is relatively simple and the cost is also low, suitable for scenarios with small battery capacity and low heat dissipation pressure.

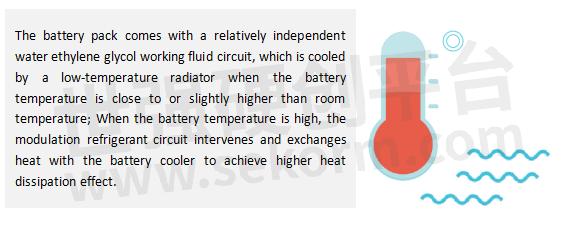

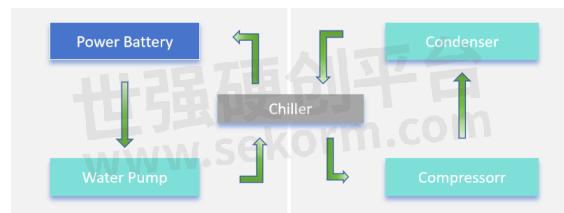

In terms of actual usage, liquid media has a high heat transfer coefficient, large heat capacity, and faster cooling speed, so it has a better effect on improving the uniformity of battery temperature. Liquid cooling scheme is currently the mainstream solution.

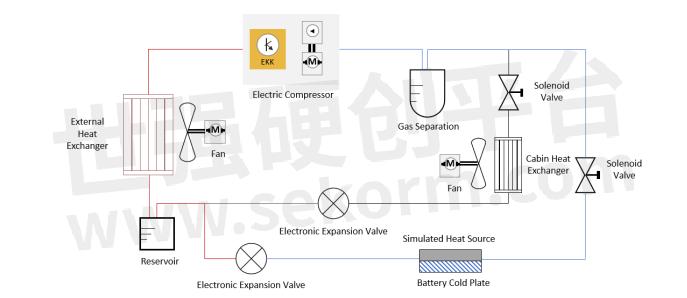

Direct refrigerant cooling technology can further improve the cooling effect on the battery, but the uniform temperature design of battery evaporators is a technical difficulty. The general requirement is that the temperature difference between the battery cells in the battery system should not exceed 5 ℃ (cooling condition+heating condition). At present, refrigerant direct cooling has not yet become the mainstream design solution in the industry.

Walmate's Battery trays and energy storage liquid pack boxes have become the preferred choice for many new energy vehicle manufacturers, energy storage product manufacturers. At the same time, Walmate also provides professional technical services and looks forward to conducting good technical exchanges with you.

- +1 Like

- Add to Favorites

Recommend

- Application of Friction Stir Welding Technology in Battery Tray Manufacturing

- How to effectively prevent or reduce the impact of thermal deformation of battery tray welding?

- Discussion on the Development of Battery Tray for New Energy Vehicles

- What is a Lithium-ion Battery Cell, Battery Module, and Battery Pack?

- 2022 Commercial UAV EXPO | Grepow shows it‘s key products: Tattu Smart Battery, Smart Drone Battery, and TA3000 Charger

- Modular Battery Different than Ordinary Battery

- Is the Button Battery a Lithium Battery or a Dry Battery?

- Omnergy Brand Blister Package Lithium Battery- Compact Lithium Battery with Strong Battery Core, Intelligent Application of “strong Core“ Design

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.