Ball Bearings——The Staple Of The Industries

The source of MinebeaMITSUMI's ultra-precision machining and mass production technologies, supporting the world of manufacturing with a single piece of ultra-precise component

Did you know that, almost without exception, the moving machines around us perform diverse functions with the help of bearings? In particular, miniature & small sized Ball Bearings are indispensable components in moving machinery, to the extent that they have been referred to as "the staple of the industries."

In the process of the development and manufacture of these miniature & small sized ball bearings, MinebeaMitsumi has refined its ultra-precision machining and mass-production technologies. Today, MinebeaMitsumi boasts the top share in the global market for miniature & small sized ball bearings and underpins the world's manufacturing industry.

A precision of the bearings is directly linked to a precision of the machinery

All moving machines have rotating axes. Those axes are supported by bearings. Of a wide variety of bearings available, MinebeaMitsumi's greatest strength lies in miniature ball bearings with external diameters up to 22mm.

Ball bearings use the low-friction rolling of balls to realize the smooth rotation of the shaft and the efficient transmission of kinetic energy to the various parts of the machine. This contributes to energy savings, longer life and reduction of breakdowns for the machinery. A precision of the bearings is linked directly to a precision of the machinery.

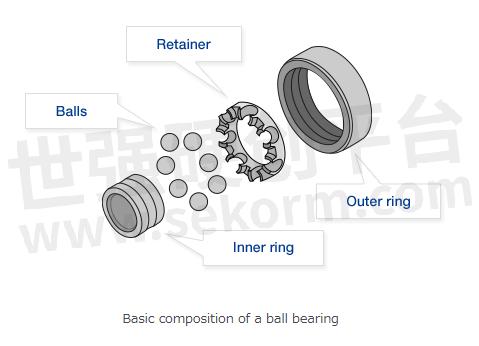

Basic mechanism of ball bearings

Ball bearings consist of four components – an outer and inner ring, a retainer, and the balls. The outer and inner rings support the rotational motion, the balls reduce the friction from that rotational motion, and the retainer keeps the balls in place. Lubricant is also added to make the movement even smoother, and some form of shielding is applied to prevent the lubricant from leaking.

Demand is growing for miniature & small sized ball bearings as we make further progress in realizing downsizing of machines

Bearings are certainly used in every moving product or merchandise from household electronic and electrical appliances such as printers and vacuum cleaners to automobiles and medical devices. One could even say that it would be impossible to operate these machines without bearings. Moreover, as machines have become increasingly downsized in recent years, demand for smaller, higher-precision bearings has grown. The miniature & small sized ball bearings born of MinebeaMitsumi's ultra-precision machining technologies are contributing greatly to the manufacturing industry all over the world.

MinebeaMitsumi's ultra-precision ball bearings, which are created from our uncompromising focus on ultra-precision technology

MinebeaMitsumi started its life as Japan's first specialised manufacturer of miniature ball bearings in 1951, and bearings have remained a primary focus of its business ever since. Our bearings are tiny components of just a few dozen millimeters in size, but they represent an aggregation of the technology and know-how that MinebeaMitsumi has cultivated for more than half a century.

World's smallest ball bearing with an external diameter of just 1.5 mm

World's smallest steel ball bearing capable of being mass produced was born of MinebeaMitsumi's passion for ultra precision. Although it is tiny, its precision and performance are comparable with other bearings. These bearings are being installed in Japan's finest mechanical watches, and we expect their applications to expand into a variety of fields and products in the future.

The use of tiny at just 1.5 mm in diameter, in a variety of applications is expected to grow in the future.

Polished to the nano-level Ra (surface roughness). Ultra high-precision balls created from ultra-precision machining

The smooth rolling motion of bearings is highly dependent on the precision of the balls. Balls that may look smooth at first glance can be found to have rough surfaces when examined with a microscope. To minimize frictional resistance to the greatest extent possible, MinebeaMitsumi bearings are fitted only with ultra high-precision balls that have been polished to the nano-level Ra (surface roughness).

Balls that underpin the precision motion of the bearing.They are meticulously polished to reduce friction resistance to the minimum extent possible.

Ultra-precision machining and mass production technologies have been made possible through the utilization of know-how cultivated by the development and manufacture of ball bearings

Along with its ultra-precision machining technologies, another of MinebeaMitsumi's strengths lies in its mass-production capabilities. Even if a company is able to make the most high-precision products, unless it can provide a steady supply of those products to the market, it will be unable to support the manufacturing industry. In particular, with numerous ball bearings often used in a single piece of machinery, the ability to mass-produce this "staple of the industries" is essential. Ultra-precision machining and mass production technologies have been cultivated by the development and manufacture of ball bearings.

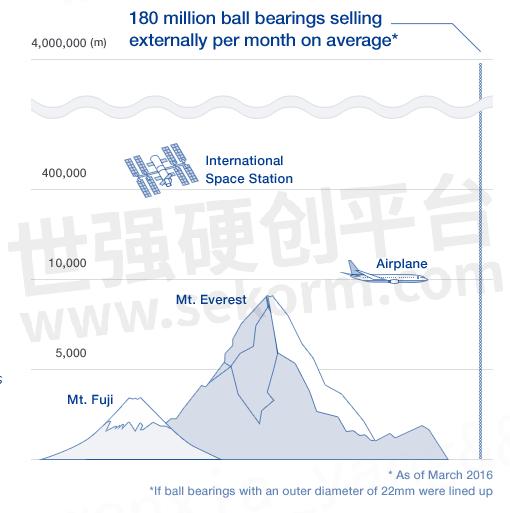

External sales target of 180 million units a month. Astonishingly large mass-production capacity that could stretch into space

As of March 2016, MinebeaMitsumi has an external sales target of an astounding 180 million ball bearings a month. Taking an example of our 22-mm diameter product, if that many ball bearings were stacked one on top of the other, it would produce a column of around 3,960 km in height. That is high enough to extend beyond the earth and reach out into the space. This ability to produce ball bearings and supply them to the global manufacturing industry in such astonishing quantities is one of MinebeaMitsumi's major strengths.

Culture of in-house manufacture and vertically-integrated production system constituting the dual pillars of MinebeaMitsumi's ultra-precision machining and mass production technologies

For MinebeaMitsumi to create systems for ultra-precision machining and mass production of ball bearings, it was vital to ensure that it would made improvements at the component and production equipment levels. While it is common for manufacturers to purchase various components from external suppliers, MinebeaMitsumi, in its quest for precision of its product parts, moved to in-house manufacture of all its components. It also made its own modifications and innovations to purchased production equipment and jigs to achieve efficient mass production. This process of trial and error fostered a culture of in-house manufacture in MinebeaMitsumi, as well as its vertically integrated manufacturing system, which controls all processes from development through to manufacture and testing.

There are many different varieties of production system, each of which has its own advantages and disadvantages. MinebeaMitsumi decided to introduce this vertically integrated manufacturing system so that it could focus uncompromisingly on its pursuit of ultra precision and ensure a steady supply of its products as a bearings manufacturer. All aspects of production, from design and development to the manufacture of each component, the production of jigs and tools to make those components, right through to the assembly of components, are performed in-house. It is thanks to this system that MinebeaMitsumi has been able to achieve its ultra-precision machining and mass production technologies. Every single process in the manufacture of ball bearings is imbued with MinebeaMitsumi's passion for ultra precision.

- +1 Like

- Add to Favorites

Recommend

- High-Heat-Resistant Ball Bearing Unit for Automobile Turbochargers

- Alliance Memory 512Mb (x8 and x16) DDR3 and DDR3L SDRAMs in the 78-ball and 96-ball FBGA Packages

- 8Mb to 128Mb High-Speed CMOS PSRAMs in 6mmx7mmx1mm 48-ball FPBGA and 4mmx4mmx1mm 49-ball FPBGA packages

- Alliance Memory High-Speed CMOS PSRAMs Offer Densities From 8Mb to 128Mb in 48-Ball and 49-Ball FPBGA Packages

- Alliance Memory Introduced High-Speed DDR2 DRAMs With 512Mb and 1Gb Densities in 60-Ball (x8) and 84-Ball (x16) FBGA Packages

- Alliance Memory Expanded Lineup of DDR3 and DDR3L SDRAMs With 512Mb x8 and x16 Devices in 78-Ball and 96-Ball FBGA Packages

- Alliance Memory Launched High-Speed CMOS DDR3 SDRAMs With 1Gb, 2Gb, and 4Gb Densities in 78-Ball and 96-Ball FBGA Packages

- Mitsumi MMR920 Pressure Sensor is Ideal for Water Level Measurement in a Smart Water Bottle Due to Its Small Size, Low-cost, and Liquid Compatibility

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.