High-Heat-Resistant Ball Bearing Unit for Automobile Turbochargers

Realized by MinebeaMITSUMI's global production network, Trump card for fuel economy improvement and engine downsizing

As public eco-awareness has been rising and environmental regulations are being strengthened worldwide, automobile manufacturers devote themselves to the realization of new eco-friendly vehicles. One solution to do this is engine downsizing, and a turbocharger, which increases an engine's efficiency and power output while maintaining the performance of conventional engines, has come into the spotlight. MinebeaMitsumi succeeded in developing a next-generation, High-Heat-Resistant Ball Bearing Unit that directly improves turbocharger performance.

Turbocharger with potential for rapid demand expansion

Turbochargers, in their heyday in the 1980s, were installed in many racing cars and sports cars to enhance the speed and maximum output of the automobiles. In those days, there was a trade-off relationship between the turbocharger and fuel consumption. Recently, a turbocharger has attracted attention once again as a device for boosting the insufficient output of engines that are downsized to meet environmental restrictions. Thus, its arena of applications has been expanded to general automobiles and eco-cars as well.

High-heat-resistant ball bearing unit for automobile turbochargers

Bearings that determine a turbocharger's performances

A turbocharger is a device to increase an engine's power output with a smaller engine capacity by improving the engine's combustion efficiency through the recycling of exhaust gases that are normally discarded.

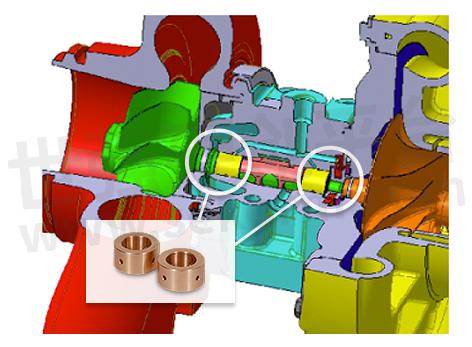

A turbocharger harnesses exhaust gas pressure emitted from the engine cylinder to drive a turbine and a compressor mounted on the same shaft. Air taken in by an automobile is compressed by the compressor and sent to the cylinder, which increases air intake and improves combustion efficiency. The turbine and compressor both play important roles to efficiently send compressed air to the engine. In 2008, MinebeaMitsumi started developing a new type of bearings for a turbine main shaft that directly influences the rotational efficiency.

Mechanism of turbocharger

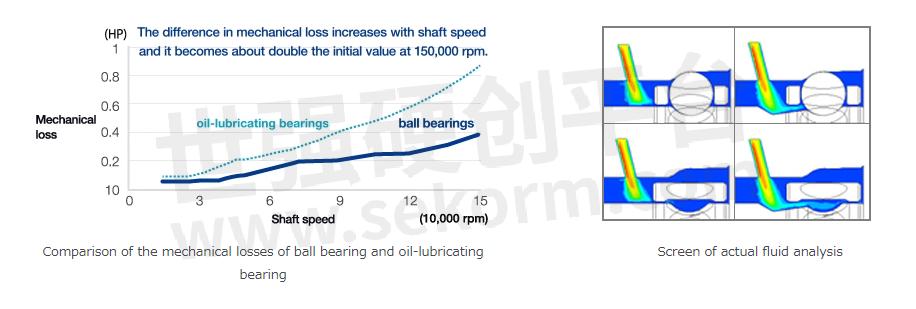

The bearing for turbine main shafts is used for the turbine driven by ultrahigh-temperature exhaust gases exceeding 800°C as the power source, and it must withstand ultrahigh speed of over 200,000 revolutions while continuously immersed in oil. For this reason, many turbochargers for general automobiles used oil-lubricating bearings that are highly resistant to harsh environments. However, since the friction resistance of oil-lubricating bearings increases at the time of acceleration and deceleration due to its structure, the speed following capability is inferior to that of ball bearings (particularly when an engine starts at the low temperature). This generates a time lag between the increase in intake air pressure and the step-in operation of the accelerator pedal. Consequently, the driver feels the acceleration to be slow, and depresses the accelerator pedal more than necessary, thereby resulting in poor fuel economy. In actual city driving, since acceleration and deceleration are frequently repeated, a series of those steps tend to affect practical fuel economy.

Conventional oil-lubricating bearing (also known as sleeve bearing or metal bearing)

To address these issues, we had to improve the following four main points for the new type of ball bearing unit: Downsizing along with an engine unit downsizing, high durability, high-heat resistance and low torque. In addition, we had to mass produce the bearings so that they would be widely adopted for use in general automobiles and eco-cars. MinebeaMitsumi, which has been continuously improving bearing production technologies since its establishment, has begun to tackle this challenge.

Requirements for the new bearing

Development of high-heat-resistant ball bearing unit to meet various requirements

MinebeaMitsumi has improved combustion efficiency and reduced the time lag between the pedal operation and automobile acceleration by adopting high-heat-resistant ball bearings instead of oil-lubricating bearings.

Three shaft diameters, 6 mm, 10 mm and 12 mm, are available. Displacements from 1.4 to 10 L are supported.

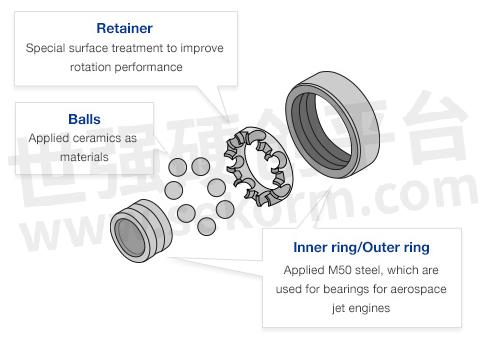

Compared to oil-lubricating bearings, the structure of high-heat-resistant ball bearings is more complicated. However, we solved the issues of durability and heat resistance by combining parts made from different materials. For the inner race and outer race, we adopted M50 bearing steel that is also used for the main bearings of aircraft jet engines; and for balls, we adopted lightweight ceramic materials with low calorific value that are suitable for high revolution. We also applied special surface treatment to the retainer to improve the balls' rotation efficiency. Besides downsizing, unitization allowed us to reduce the assembly work in the turbocharger manufacture and improve the stability and balance of the entire part.

Sectional view of ball bearing unit

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.