Easy Guide on Open Loop vs. Closed Loop Control in DC Cooling Fans

Closed loop fan control has often been associated with external controllers to modify a DC fan’s performance. However, many SANYO DENKI Fans utilize an internal closed loop speed control to enhance performance.

This brief article will explain the differences between open and closed loop control and how to tell what type of loop control the fan model has.

Open Loop Control

Open loop control is basically just a free running motor and is the simplest design. It has no internal feedback circuitry and so the speed (RPM) can be affected by changes in pressure or temperature. Most of our older fan models are open loop controlled.

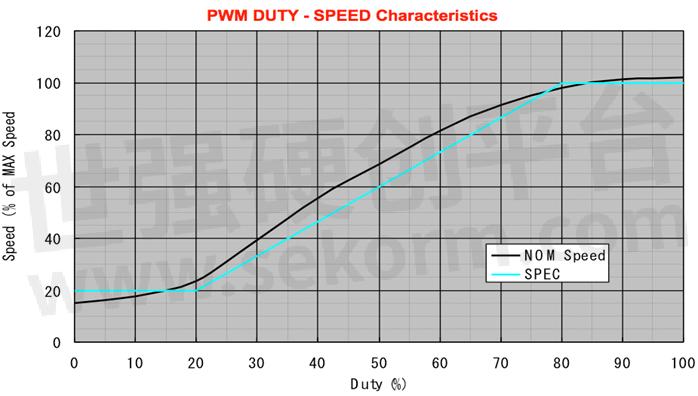

In order to tell if a DC fan is open loop controlled, look at the Speed vs PWM duty cycle graph provided in the data sheet. As you can see below, the nominal speed (black line) is not linear over the PWM duty cycle range.

Advantage: Lowest cost because there is no feedback circuitry.

Disadvantage: Will not self-correct the RPMs when conditions change.

Closed Loop Control

Over the last decade, many of our new fan models have closed loop control which keeps the speed (RPMs) constant regardless of temperature or back pressure variations. This is accomplished by adding a feedback circuit to the motor control via an internal tachometer signal so that the feedback circuit automatically makes corrections to bring the speed back to nominal.

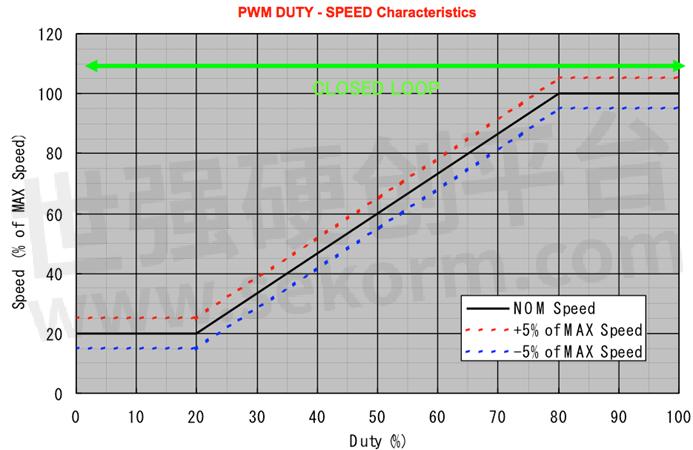

For example, below is a Speed vs PWM duty cycle graph showing a fan with closed loop control. As you can see, the RPMs are linear over the PWM duty cycle range and will autocorrect the speed up to +/- 5% of the nominal value over the duty cycle range. This percentage can vary based on the fan model.

Advantage: Will autocorrect the RPMs based on external changes to maintain a constant airflow and thus provides the desired temperature in a system.

Disadvantage: Adds a small cost increase since additional internal feedback circuitry is needed.

In closing, DC fans with closed loop control features are a great way to maintain constant fan performance over the PWM duty cycle even when changes in system pressure or temperature occur.

- +1 Like

- Add to Favorites

Recommend

- Current Specifications of DC Cooling Fans You Need To Know

- The Evolution of High-Performance DC Cooling Fans in Modern Technology

- New Performance Benchmark Set By The 9RA Series Cooling Fans of SANYO DENKI

- Delta, The World‘s No. 1Leader in Brushless DC Fans and Cooling Solutions,Signed an Authorized Distribution Agreement with Sekorm

- From Design to Impact: The Science Behind Energy-Efficient Cooling Fans

- Delta Pulse Width Modulation PWM Fans Have Advanced Cooling Solutions, Deliver Best Performance and Greater Effciency

- How to Use PWM Speed Control to Improve Efficiency of Cooling Fans

- Delta Superflo Bearing Fans with Permanently Lubricated Spinning Mechanism Offer High Reliability and Reduce Costly Maintenance Cycles for Consumer Product Cooling Applications

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.