From Design to Impact: The Science Behind Energy-Efficient Cooling Fans

Cooling Fans play a critical role in various applications, from industrial processes to data centers. SANYO DENKI recognize the urgency of energy efficiency. SANYO DENKI mission is to reduce power consumption in cooling fans, thereby decreasing reliance on fossil fuels and curbing greenhouse gas emissions.

Beyond energy efficiency, SANYO DENKI also focuses on enhancing the longevity of cooling fans. By doing so, SANYO DENKI contributes to better resource utilization and waste reduction. These efforts align with the global Sustainable Development Goals (SDGs), as depicted in Figure 1. In this blog, SANYO DENKI explores the innovative technologies we’ve developed to achieve these vital objectives.

1. Simulation-based automated design optimization: Design impeller and frame for lower power consumption and noise

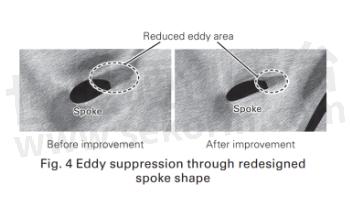

To lower power consumption in cooling fans, SANYO DENKI has been utilizing simulation-based design optimization, along with SANYO DENKI’s expertise, to ensure both the impeller and frame demonstrate good aerodynamic performance and the stator core, windings, magnets, and drive circuit provide high motor efficiency.

2. Visualization of Airflow: Assess turbulence and eddies to refine impeller and frame shapes

To refine the impeller and frame shapes generated by the automated optimization, SANYO DENKI utilizes simulations to visualize airflow. Unsuitable blade shapes can induce turbulence and eddies, diminishing efficiency and increasing noise. Simulation-based airflow visualization allows us to assess turbulence and eddies, guiding improvements. Figure 4 demonstrates reduced eddies by modifying the frame spoke shape.

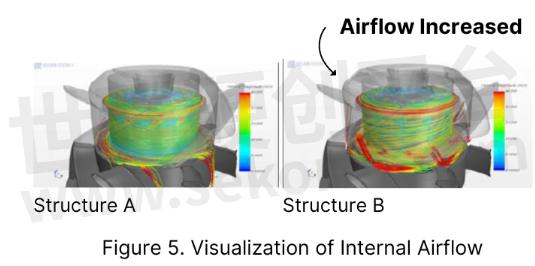

3. Visualization of internal airflow: improving self-cooling structure for lower motor and bearing temperatures

SANYO DENKI utilizes simulation-based airflow visualization to enhance service life. Employing a self-cooling structure maintains low motor and bearing temperatures, extending longevity—simulations aid in designing a structure with improved self-cooling capability. Figure 5 depicts internal airflow visualization, showing Structure B’s enhanced airflow compared to Structure A, indicative of superior self-cooling capability.

With simulation-based automated design and airflow visualization, SANYO DENKI can now design impellers, frames, motors, and structures to create cooling fans with reduced power consumption and extended lifespan.

Applied Engineering: SANYO DENKI Fans Contributing to Achieving a Low-Carbon SocietyThe 9RA Type Fan with Low Energy Consumption and Low Noise

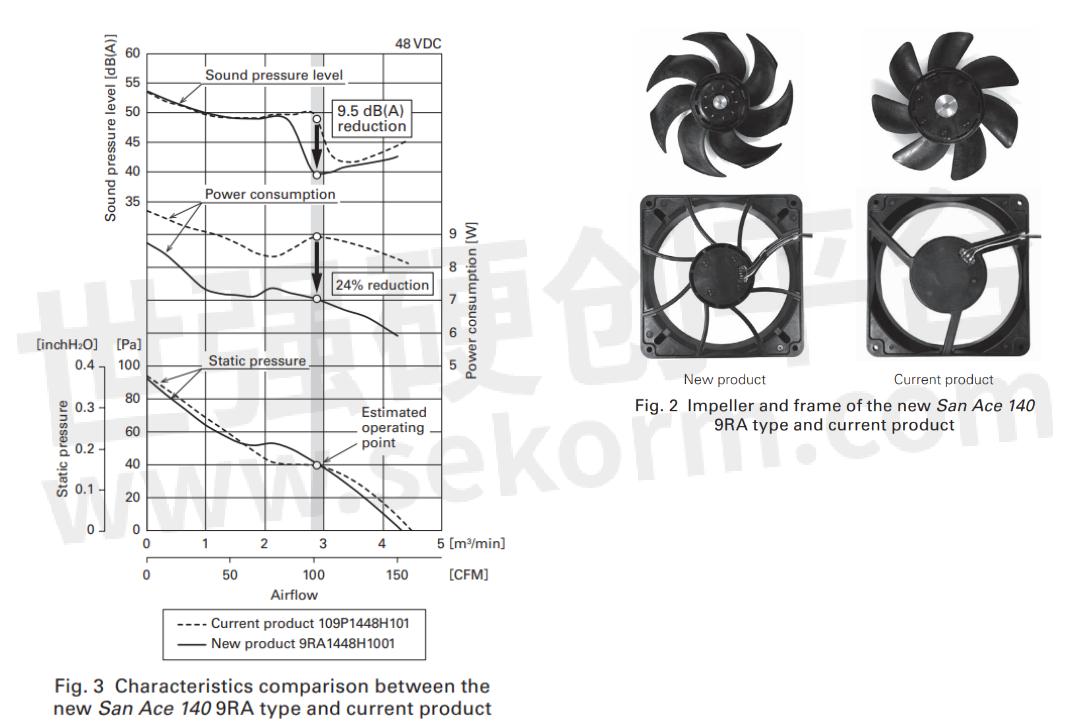

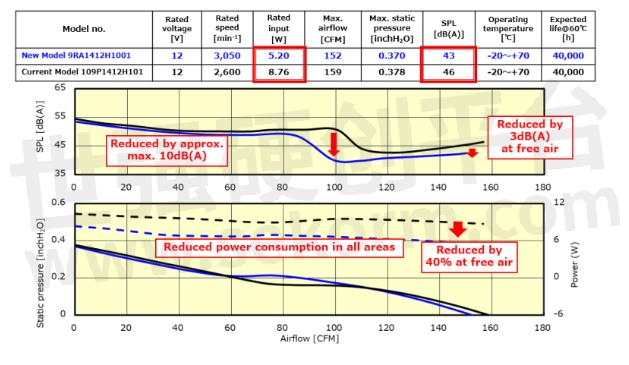

The San Ace 9RA type cooling fans, range from 60 × 60 mm to 140 × 140 mm, consuming less power and generating less noise than current models while maintaining size and cooling performance. Its significantly reduced power consumption results in 41% lower CO2 emissions over its lifecycle compared to the current products, per SANYO DENKI LCA calculation software.

What is Lifecycle Assessment (LCA)?

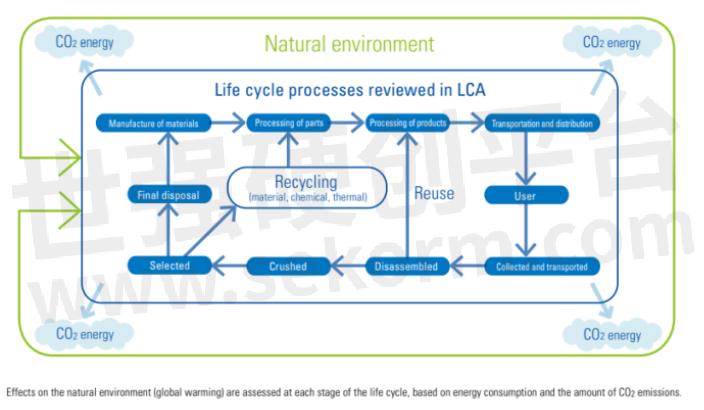

Life Cycle Assessment: LCA is one of the techniques used to provide a general quantitative measure of levels of environmental impact including global warming that products have through their life cycles. SANYO DENKI evaluates the environmental compatibility of a product using this method.

- +1 Like

- Add to Favorites

Recommend

- New Performance Benchmark Set By The 9RA Series Cooling Fans of SANYO DENKI

- SANYO DENKI Introduces the 92×92×38mm DC Fan: The Latest Addition to the Low Noise 9RA Series, Prioritizing Energy Efficiency

- SANYO DENKI Launches 92×92×25mm San Ace 92 9RA Type DC Fan with the Lowest Noise up to 23dB

- SANYO DENKI Launched 120×120×25mm San Ace 120 9RA Type DC Fan with the Lowest Noise up to 28dB

- SANYO DENKI Launches 120×120×38mm San Ace 120 9RA type DC Fan with the Lowest Noise of 37dB Min and a Wide Variety in 12/24/48 Voltage

- Trouble With Electromagnetic Environments? SANYO DENKI’s Expert EMC Solutions Help

- SANYO DENKI Fan’s Quiet But Powerful Role In The Medical Industry

- SANYO DENKI Launches 80×80×38mm DC Fan with the Lowest Noise in the Industry

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.