MinebeaMitsumi Thin Lens Challenge toward the Future of Lighting

MinebeaMITSUMI had developed a broad range of products in the fields of machined components and electronic devices and components while focusing on the concept of ultra-fine, and the next challenge was the lens for LED lighting. By applying the optical simulation technologies that had been cultivated in the production of thin light guiding panels for LED backlights to be used for smartphones where MinebeaMitsumi is proud of the number one global market share, MinebeaMitsumi has developed a thin lens for LED lighting, which is an unprecedented achievement in the industry.

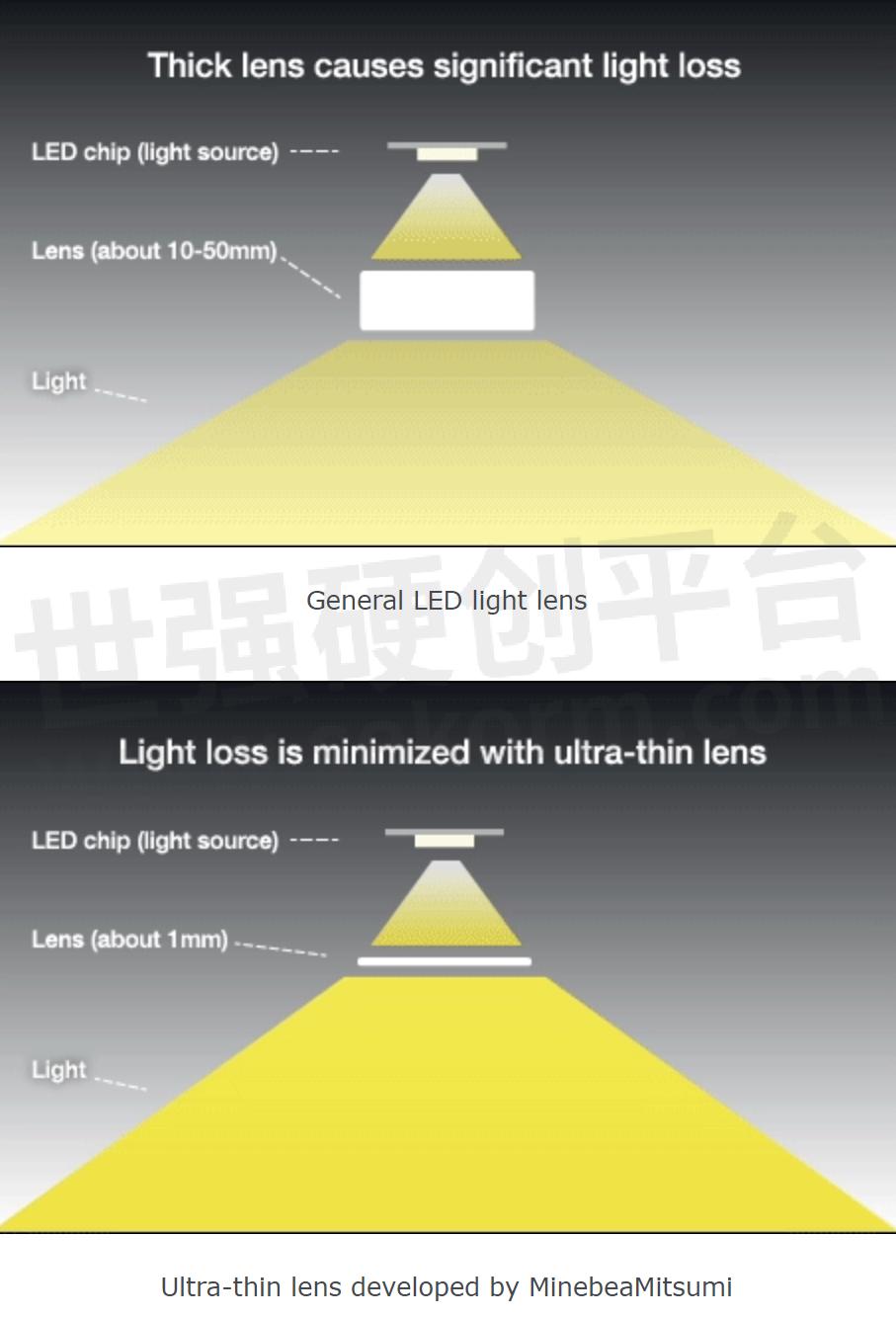

Machined with an ultra-fine process, the lens has a thickness of just 1mm, which will broaden the potential for LED lighting.

The expanding role of LED lighting and its challenges

The range of applications of LED lighting continues to expand, with its excellent light adaptation, nearly no irradiation of infrared or ultraviolet radiation, and ecological characteristics such as long life and low power consumption. LED lighting emits intense light from light emitting diodes, as opposed to the conventional lighting typified by incandescent bulbs or fluorescent lamps, which emit light equally in all directions-360 degrees. Highly directional lighting equipment such as ceiling-mounted light fixtures allows you to implement structures that make the most of the light, whereas the difficulty of emitting light that is diffused evenly is regarded as a weak point of such lighting devices. When you can freely direct light with highly directional LED lighting, you can also diffuse the light in all directions, as a matter of course, which should lead to new applications of LED lighting. MinebeaMitsumi has launched the development of a lens for lighting that will be capable of skillfully controlling light.

The lens that will be vital for LED lighting

By using a special lens to collect and diffuse the light generated by light emitting diodes, the mechanism of this LED lighting spreads the light efficiently to brighten the entire space. The lens of the LED lighting plays a vital role in affecting the quality of the lighting itself. Up to now, a thick lens known as a cup-shaped lens was commonly used as the part of the lens needed for the complex operations of the light. Although the cup-shaped lens was excellent for adjusting the angle of the light, the light tended to be attenuated in the lens, resulting in a loss of the light generated by the light emitting diode. Although MinebeaMitsumi actually manufactured a collimating lens drawing on its optical simulation technologies, there was still room for improvement with respect to the attenuation of light. The light transmittance of the lens is also directly connected with the power consumption of the LED lighting. Can't we further reduce the loss of light, and can't we collect and diffuse light more efficiently? MinebeaMitsumi has ultimately achieved one of the solutions toward realizing the lens of the future by drawing on its specialty light guiding panel technologies to make a thinner lens.

Both collecting and diffusing light in a 1mm lens

By arranging several optical lenses to carve a fine prism pattern, MinebeaMitsumi has developed a lens for LED lighting, having the thickness of only 1mm, which can skillfully control light.

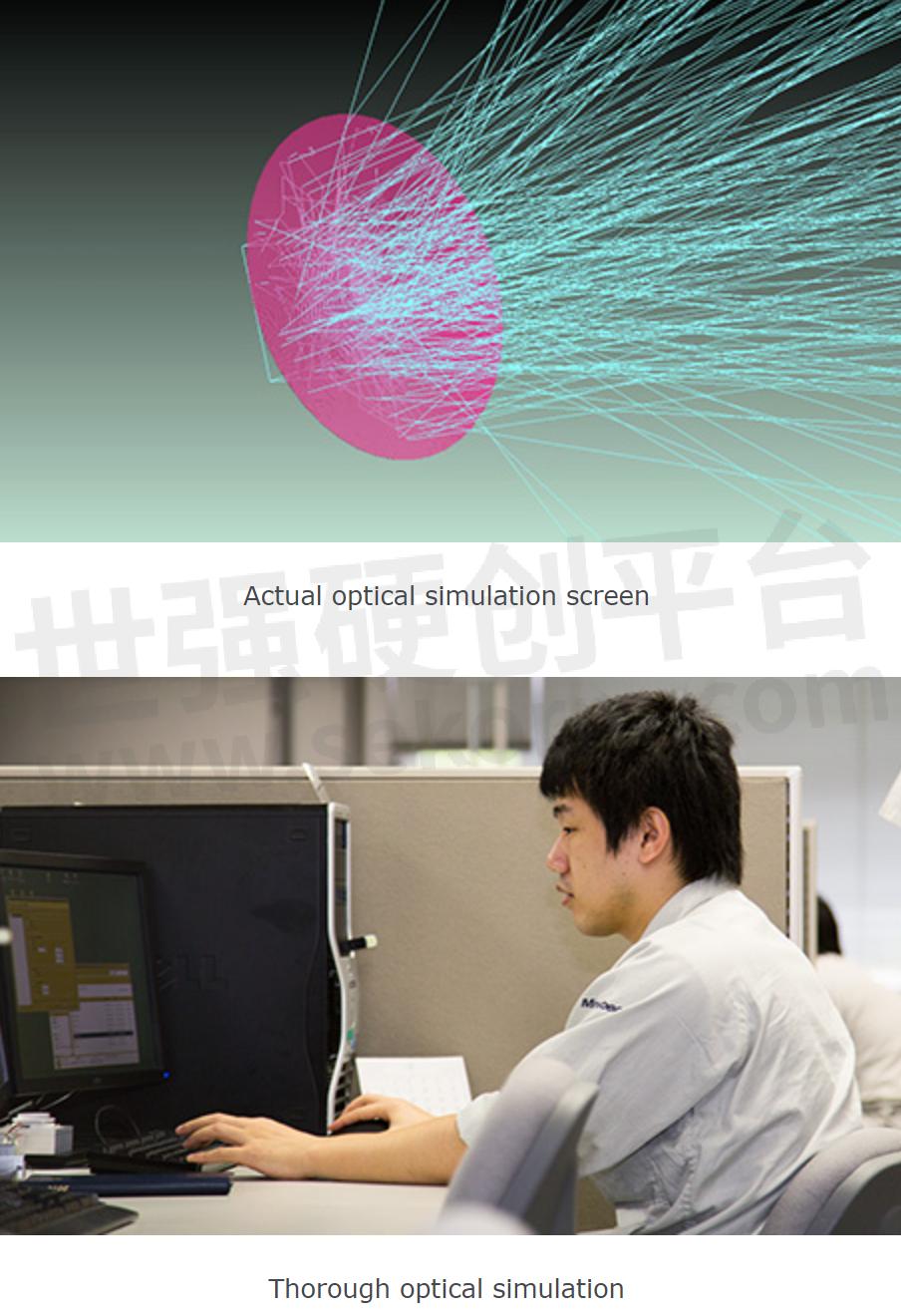

Through optical simulation technology

MinebeaMitsumi thoroughly investigated optical simulation in developing a thin lens with exhaustive optical simulation technologies. There was a need to calculate the patterns of ultra-fine optics (elements) using a thin lens to collect and diffuse light, which had conventionally been done with a thick lens. Toward that end, we conducted precise calculations of the reflection angle and attenuation rate in the lens countless time, applying the optical simulation expertise accumulated in developing an ultra-thin 0.3mm light guiding panel.

At a glance, the 1mm lens may appear to be a single plate, but the two sides of the front and back have entirely different machining applied, as they perform collection and diffusion of the light, respectively. The light collection surface is formed with optical elements that mix light in order to suppress uneven illumination in the light generated from the light emitting diode and the uneven color known as yellow ring. The diffusion surface combines two lenses with different optical properties in order to achieve uniform diffusion of the light. A Total Internal Reflection (TIR) fine prism is used as a base to achieve uniform diffusion of light in the lens, and a Fresnel lens is used to perform fine adjustments in the center of the lens, which requires precise guiding control. In addition, carefully mixing the light in the lens allows you to consistently generate "high quality" light irrespective of the quality or quantity of the light emitting diodes. With respect to the lens development required for lighting applications, we have also achieved rapid development of lenses with a variety of optical characteristics, through the application of the most suitable optical designs developed by thorough optical simulation.

Plastic molding technologies and mold processing technologies that support manufacturing

In terms of lens manufacturing, MinebeaMitsumi draws on its world-class molding and processing technologies. Making full use of the mold processing technologies cultivated in machining-including bearings and resin molding technologies cultivated in gear molding-MinebeaMitsumi created an unprecedented and epoch-making thin lens for LED lighting carved with an ultra-fine optical pattern.

The future of LED lighting changed by the thin lens

While LED lighting effectively saves around 60% of the energy compared to conventional light bulbs and fluorescent lamps, using this thin lens achieves an additional energy savings of about 30%. By adjusting the optical pattern of the lens, you can skillfully control the direction of the light, allowing for various combinations of light distribution and diffusion.

If you use a thin lens in a street light that serves to illuminate the road, for example, you can control the direction of the light so that it illuminates only the road brightly. In addition to improving visibility on the road, it solves the problem of uselessly illuminating the surrounding buildings and the like as well.

Features include not only directivity of the light, but also further enhanced diffusivity. By introducing a thin lens in illuminating the room, for example, you can create a soft light and in turn, a comfortable space. In fact, leading U.S. lighting equipment manufacturers are beginning to incorporate MinebeaMitsumi's thin lens in lighting equipment focusing on design and using the unprecedented thinness and performance in a variety of fields.

In fact, MinebeaMitsumi was the last entrant in the industry to enter the lighting device business. With respect to small LED backlights for smartphones, however, MinebeaMitsumi boasts the number one global share in this particular segment, and this business has grown to line up shoulder to shoulder along the traditional mainstay business of machined components.

MinebeaMitsumi thoroughly devoted itself to promoting the business in the process, and by applying the accumulated optical simulation technologies, achieved significant functional improvements in lenses for lighting that had not even been considered in the past. MinebeaMitsumi continues to conduct research night and day today for the light that is closely related to our lives at all times of the day—morning, noon, and night. We need lighting for all aspects of our lives. MinebeaMitsumi will continue to challenge the potential for lighting through the technologies for skillfully controlling light going forward as well.

- +1 Like

- Add to Favorites

Recommend

- DapuStor‘s Roealsen5 and Xlenstor2 Series Enterprise SSDs Earn PCI-SIG PCIe 4.0 and UNH-IOL Certifications

- Coherent Announces Comprehensive Micro Lens Array (MLA) Solution for Beam Collimation and Coupling

- New LED lighting “SALIOT“: A Revolutionary Lighting Able to Completely Control Light

- SPIE Photonics West 2022 to Include Kyocera’s Ceramic Package and Optical Component Solutions

- An AEC-Q100 Qualified QVGA Time-of-flight Sensor MLX75026 which Further Expands the ToF Sensors From Melexis

- Expanded Beam technology and Rosenberger‘s Expanded beam connectors

- DapuStor got VMware IOVP certification for the full range of PCIe Gen4 SSDs

- Mitsumi MMR920 Pressure Sensor is Ideal for Water Level Measurement in a Smart Water Bottle Due to Its Small Size, Low-cost, and Liquid Compatibility

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.