New LED lighting “SALIOT“: A Revolutionary Lighting Able to Completely Control Light

MinebeaMITSUMI has sent tremors through the lighting industry with their development of a thin lens for LED lighting that utilizes super-thin light-guiding panel technology. SALIOT combines the optical technology represented by this super-thin lens with motors, power supplies, and wireless communication, along with many other different components and technologies. SALIOT, the first in the industry to be equipped with its revolutionary functions, is part of the future of lighting envisioned by MinebeaMitsumi. Able to freely control light and create expressive environments for a variety of different situations, SALIOT can open the door to new possibilities in the lighting industry.

An industry-first breakthrough function enabling the spread of light to be freely adjusted

The appearance of light required for a car dealership showroom, for example, differs from that for a museum. In the past, lighting equipment would need to be changed in order to address individual applications, but with SALIOT, just one equipment can provide a variety of lighting presentations to match any situation. This is made possible by an industry-first* function enabling the light distribution angle (the angle at which light spreads) to be changed from 10° to 30° as desired. The positioning can also be freely changed with its pan and tilt function, a single equipment can be adjusted to provide lighting that perfectly suits any situation. If multiple SALIOT units are combined, the lighting of a space can be presented in an even wider variety of configurations. Furthermore, the color temperature and average color rendering index can also be selected to match any situation or mood.

*source: MinebeaMitsumi, as of July 2015

Presentation of a car dealership, implemented to accompany the announcement of new cars or seasonal events. Flexible adjustment of the light distribution angle can be instantly made from narrow (10°) to wide (30°).

Functional light distribution designs using spotlights can demonstrate advanced "wall washer" effects where wall surfaces are lit gently and softly. This can enhance the appeal of exhibits and displays.

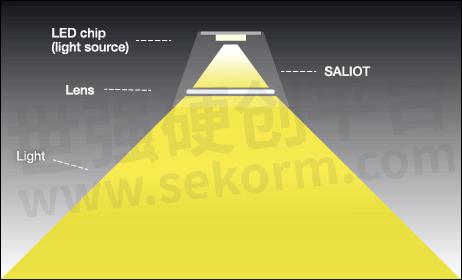

A super-thin 1-mm lens and compact motors create light that can be freely controlled

The industry-first light distribution angle varying function is supported by a super-thin, lens with a thickness of no more than 1mm, developed specifically for LED and compact motors that are incorporated into SALIOT. The lens has a fine prism pattern carved into it, allowing it to suppress light loss to the minimum level possible. This has enabled it to achieve more efficient light convergence and diffusion than lenses of conventional thickness, even while being only 1mm thick. Also, in order to change the light distribution angle, the distance between the light-emitting diode and the lens is controlled by compact motors. These compact motors also control the unit's pan and tilt functions. The lens and motors represent a fusion of optical technology and electronics devices only possible through MinebeaMitsumi's vertical integration. This is one reason why it is able to create such highly-variable light.

The distance between the light-emitting diode and the lens is changed to freely control the light distribution angle

Super-thin lens developed specifically for LED, with a fine prism pattern carved into it

Remote control using Bluetooth Mesh can increase the efficiency of on-site work

The name "SALIOT" was derived from the initial letters of "Smart Adjustable Light for the Internet Of Things". The "IOT" part of its name includes one more innovative aspect of SALIOT: the ability to adjust lighting by remote control using wireless communication. In the past, if lighting mounted in high places required adjustment, work using a stepladder or adjusting rod was necessary. By equipping SALIOT with remote control functions using wireless communication, adjustments have been made simpler to perform and even more subtle adjustments can be carried out. This can help to realize improvements in work efficiency and reductions in operational costs.

Image of operation of multiple SALIOT units using a specialized application

It is envisioned that at actual work sites, multiple SALIOT units will be operated over a wide area. Therefore, the Bluetooth® Smart CSRmesh™, which is currently receiving great attention as a leading-edge technology to achieve the "Internet of Things", has been employed in its wireless technology. Operation from just a single smartphone can control up to 100 SALIOT units simultaneously. This operation can be conducted easily using a specialized application developed by our company, making it possible for detailed adjustments ranging from brightness, movement in the up, down, left, or right directions, and changes in the light distribution angle, to be made.

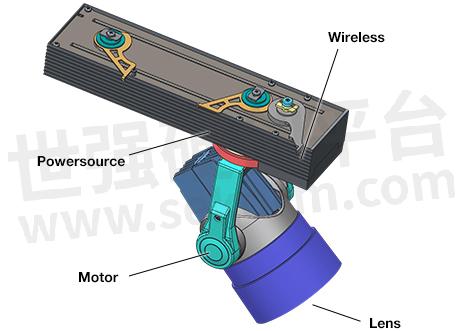

A fully realized product squeezed into a smart package

MinebeaMitsumi's main occupation is the manufacturing of high-precision components, and SALIOT is one of our few complete products. For that reason, in order to make it suitable for the marketplace, not only did it have to offer high performance, but it also needed to be compact and well-designed. It is MinebeaMitsumi's precision machining technology that has allowed us to simultaneously achieve these conflicting goals. Using MinebeaMitsumi's precision manufacturing technology, we were able to make the main components of SALIOT: the lens, motor, power source, and wireless, both high-precision and compact, and to cover it in a smart form.

Main components of SALIOT

The fusion of our company's products and technology, together with the corporate culture of MinebeaMitsumi, makes smart lighting a reality

SALIOT is a composite product that combines the diverse components and technology of MinebeaMitsumi, from its optical technology of lens to its compact motors, power supply circuits, and wireless technology. Expert personnel from a variety of departments were involved in its development. In its initial development SALIOT was confronted by issues such as noise generated at the locations of the pan, tilt and zoom functions of the light. These were resolved by revising its design with cooperation from engineers in other departments.

MinebeaMitsumi's technology was fully applied to achieve visually attractive irradiated surfaces, using highly-advanced optical simulation technology, in the development of its zoom function. Our precision component and technology capabilities, and a corporate culture that facilitated cooperative efforts with other departments, gave birth to the innovative product known as SALIOT. We will continue to enrich its lineup with various additional models such as spotlight types and down light types, while uncovering new needs in the lighting industry.

SALIOT in its prototype stage. The gears, motors, and wiring that are exposed here are all contained and stored internally in the final product.

Though our development of SALIOT started with the question from the field "If we use our company's thin motor with our thin lens, couldn't we make a movable light?," the road to completion was not an easy one. Our first challenge was to create a smooth moving mechanism, with various axis and functions, which required numerous complex redesign attempts to achieve fluid movement throughout various pan, tilt and zoom adjustments. Furthermore, Bluetooth Mesh technology was new to our engineering team and needed frequent network optimizations in order to enable precise control from a wireless device. We worked vigorously to create numerous prototypes, get customer feedback, and make necessary revisions in order to create a finished product to meet the demands of the lighting industry. With our ambition to create something that does not yet exist in the world, we made consistent progress during development and finally arrived at SALIOT.

We think that a big key to our success was using our company's diverse products and technology and considering how to achieve functionality from a variety of different viewpoints. Other key factors were our connections that go beyond the bounds of our internal departments, and our ability to easily bring ideas into concrete form thanks to the open corporate culture at MinebeaMitsumi. By further implementing light guiding panel, lens, and SALIOT into our new product development, MinebeaMitsumi's products and technology will continue to expand in breadth. Going forward, we will continue to enhance synergy with other products and technologies, and to develop new products that the world has not yet seen.

- +1 Like

- Add to Favorites

Recommend

- Mitsumi MMR920 Pressure Sensor is Ideal for Water Level Measurement in a Smart Water Bottle Due to Its Small Size, Low-cost, and Liquid Compatibility

- MITSUMI Announced that ABLIC, the Company‘s Consolidated Subsidiary, Had Decided to Acquire the Medical-related Business Operated by Socionext from Socionext

- MinebeaMitsumi Installs Large-Scale Solar Power Generation Systems at Cebu Plant

- Mitsumi Has Developed CMI-BD001 Standard Type Onboard Interface Connection Unit for Vehicle Market

- Mitsumi MMR920 Grass Bag Fill Sensor for Robotic Mowers, with Ultra-Small Footprint and High Sensitivity

- MinebeaMitsumi Thin Lens Challenge toward the Future of Lighting

- MITSUMI Onboard FAKRA Connector Series is Featured with a High-frequency Characteristic from 0 to 4GHz

- MinebeaMitsumi Notice Regarding Construction of Second Plant in Cambodia and Solar Power Generation Business in Cambodia

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.