Expanded Beam technology and Rosenberger‘s Expanded beam connectors

The current data center market has a continuous necessity to increase the demand for high bandwidth at a lower cost, additionally, new applications are demanding the arrangement of several IT equipment in edge computing infrastructures that might confront outdoor environments with severe surroundings. This is highlighting the limitations of the traditional communication architecture where we can notice major challenges on the infrastructure space cost, temperature/thermal management, and signal integrity.

New products and solutions are being developed to overcome the current challenges formed by digital transformation, where big data is being created and consumed to support critical applications of everyday life. Recent advances and new studies on fiber optic connectivity allowed the development of non-physical contacts, establishing a new technology called Expanded Beam, this new technology was created with the intention to support critical applications with severe and difficult environmental conditions.

Expanded Beam Principle:

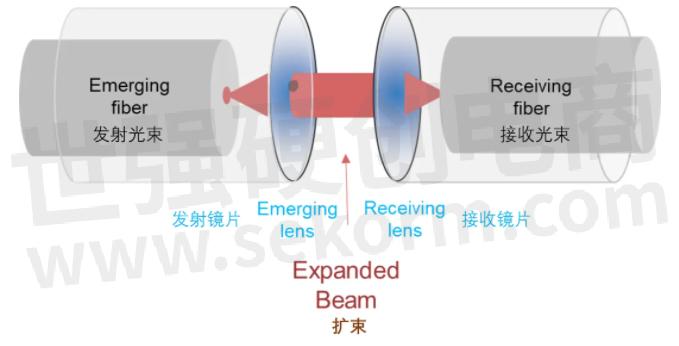

Expanded Beam Technology uses two lenses that need to match each other, one of these lenses should be located at the end of the fiber from where the light beam emerges and the other one will be located at the receiver where the fiber will be connected to. The lens where the fiber emerges will expand the light beam creating a parallel ray, then, the second lens will refocus this light and reconstruct the beam in a second fiber that has the same size as the original beam. In order to achieve the expansion and reconstruction of the light beams, the lenses must have a refractive index that can be a constant (balls lenses) or that can vary through the lens (graded-index lens).

Benefits of Expanded Beam Technology:

The expanded beam technology not only will help with the scalability and fast deployment of several applications but will also help with the reliability of the system. Data communication arrangements became more reliable because the end of the fibers does not physically touch each other, therefore the risk of chipping, scratches, or have irreversible damage in the fiber or ferrule caused by the pressure of dust particles, are being avoided when using this type of connector, making expanded beam the perfect technology to be deployed in military and any other applications that needs to support critical conditions in harsh environments.

Difference against Physical Connectors:

To compare the performance of physical connectors against expanded beam connectors, we can use two common parameters as reference:

1.Optical performance, comparing Insertion Loss (IL) and Return Loss (RL).

2.Environmental performance, comparing the performance in extreme outdoor conditions.

Optical performance

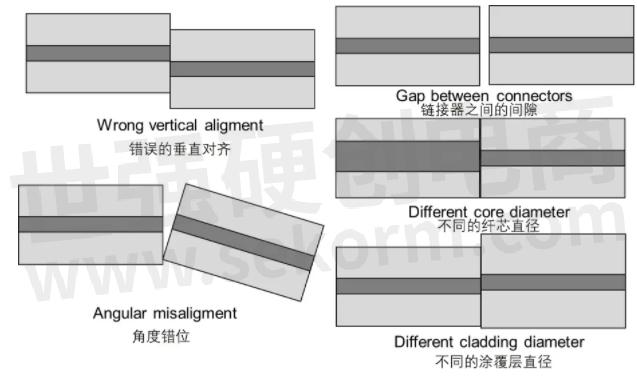

In fiber optic cables, insertion loss is the amount of light lost with respect to the light going into the fiber optic cable. The main features that need to be considered when talking about insertion loss are alignment, cleanliness, and polish. The ideal connection should perfectly align the fiber's core, unfortunately, this is very difficult to achieve due to several mismatches that can be caused by factors such as:

· Gap between the ends of the physical connectors.

· Bad connectivity alignment, meaning that the end of the fibers can be in the wrong position in any place of the axial plane.

· Different core diameter.

· Different cladding diameter.

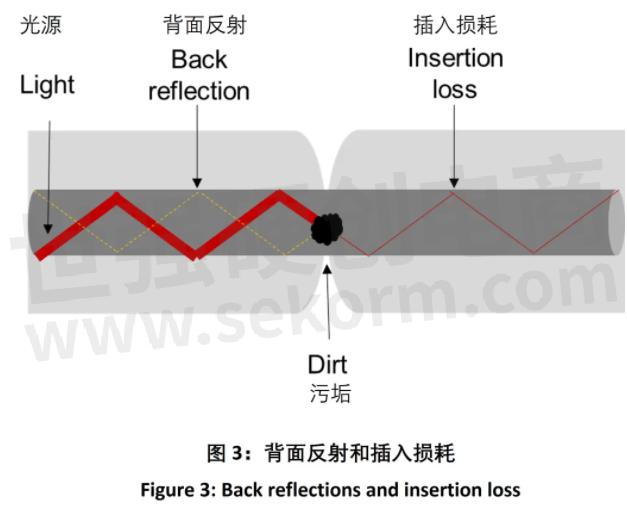

Cleanliness affect insertion loss because particles of dust in the connector end face can cause irreversible damage to the ferrule and the fiber core, as we know, fiber cores have a small diameter, and they are very susceptible to be easily contaminated. The polish affects both insertion loss and return loss, however, polish quality and polish type are the main reference in return loss influences, so it will be explained in the return loss part clarification.

Return Loss for optical fibers can be defined as the unwanted reflections back into the input path of the fiber, these smalls reflections might have an influence on the laser source causing noise or damaging the transceiver.

The most critical factors related to the return loss are the polish quality and the type of polish. Poor polish quality might generate gap separation or an angled separation between the fibers, causing differences in the refraction index between the glass and the air, transforming this in return loss.

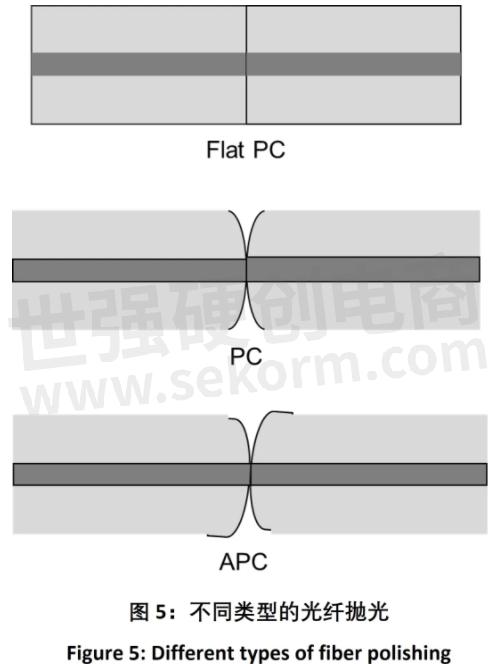

The different types of polish also affect the return loss of the connections. Flat PC polish may eliminate the refraction index difference that can be caused by bad polish; however, if any ferrule is contaminated it can jeopardize the reliability of the fiber physical contacts. PC polish uses a rounded PC polished ending, allowing only the optical fibers to touch, however, this can create unwanted reflections and these reflections will bounce back into the fiber source causing noise. Angled polish (APC) is designed with an 8 or 9-degrees angle, this angle will absorb any reflection that might occur, taking the undesirable reflected beam from the core to the cladding.

Expanded beam connectors have a limitation characteristic regarding the optical performance, these types of connectors are created having a gap separation between them, this means that the light beam must pass through few surfaces that have a different refractive index (glass - air - glass) this transition between materials generate partial reflections of the light ray, bringing as consequence an increment in the insertion loss and a higher return loss.

Environmental performance:

Both physical and expanded beam connectors have a good performance in normal environmental conditions, however, things change when we took into consideration factors like dust, sand, dirt or moisture, and liquids.

In conditions that are constantly exposed to dust, sand, or dirt, expanded beams have a clear advantage in comparison with their physical counterpart. These kinds of particles represent a big risk for physical connectors, decreasing the system reliability when these solutions are implemented in such conditions. Expanded beam solutions don’t have physical contacts that may cause permanent damage to the fiber core, meaning that small particles don’t represent a big threat, allowing to minimize the risk while increasing the reliability of the system, additionally, the cleaning and maintenance is easier and faster, which can be translated in a reduction of operational costs when deploying expanded beam connectors in such environments.

In conditions that are exposed to moisture or liquids, expanded beam connectors might have an unexpected performance. In ideal circumstances, the principle of expanded beam connectors indicate that the light ray must pass through glass-air-glass, however, in situations where the lenses are exposed to moisture or liquids, the light must pass also through the contaminant agent (glass - contaminant agent - air - contaminant agent - glass), which will reduce the performance of the system. On the other hand, physical connectors have protective mating that act as defensive shield against moisture and liquids.

Conclusion

Expanded beam is a new technology that is becoming more popular due to the new necessity of implement data transmission systems outside the traditional centralized architecture or the need to move these infrastructures to remote locations. Designers and engineers should always evaluate several aspects before taking a final decision on which solution is better to deploy. Currently, many applications and standards are being developed, meaning that both types of solutions can be implemented, however, it's important that technical personnel know the differences between both types of connectors and the environmental conditions to which they are going to be exposed. Additionally, many companies are doing research and development to reduce the weaknesses of expanded beam connectors. As a world leader of optical fiber connectors, ROSENBERGER worked along with 3MTM to develop a new connector called: 3M™ Expanded Beam Optical (EBO) Latch Connector, these innovative connectors use a new mirror reflex lens to eliminate and reduce the disadvantages of the previous expanded beam technology. If you are interested in knowing more about this new technology and the applications which are being used, please do not hesitate to send any inquiries to Optical@rosenbergerap.com our experts will help you to clarify any doubts regarding the product implementation or the deployment of your application.

Features

· The connector developed by 3M™ is less sensitive to dirt, so that multiple matings are possible with minimal cleaning effort

· 3M™ EBO offers outstanding attenuation values for singlemodeapplications - insert loss: <0.70 dB and return loss: >55 dB

· The 3M™ EBo is equipped with a ferrule supporting 12 singlemode ormultimode fibers

- +1 Like

- Add to Favorites

Recommend

- METZ CONNECT Has Expanded the Modular System of M12 Circular Connectors

- Coherent Announces Comprehensive Micro Lens Array (MLA) Solution for Beam Collimation and Coupling

- TE Connectivity‘s Expanded Overhead Connector Range is Designed to Ease Installation

- What Is Expanded Polytetrafluoroethylene

- Smiths Interconnect Expanded its L Series of Modular Connectors with The Addition of Hybrid & Pneumatic Modules

- Application Principle of Expanded PTFE

- What is the Role of Industrial Connectors? What Types of Industrial Connectors Can Be Divided into?

- RJ45 Connector for PoE+ Cabling Solution Can Provide up to 90W of Power Supply | Rosenberger

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.