What is a Silicon Anode Lithium-Ion Battery?

Lithium-ion batteries (LIBs) have become ubiquitous in modern technology, powering everything from smartphones to electric vehicles. A critical component of these batteries is the anode, traditionally made of graphite. However, recent advancements have introduced silicon as a promising alternative, leading to the development of Silicon Anode Lithium-Ion Batteries. This article delves into the specifics of silicon anodes, their benefits, and the challenges they present.

What is a Silicon Anode?

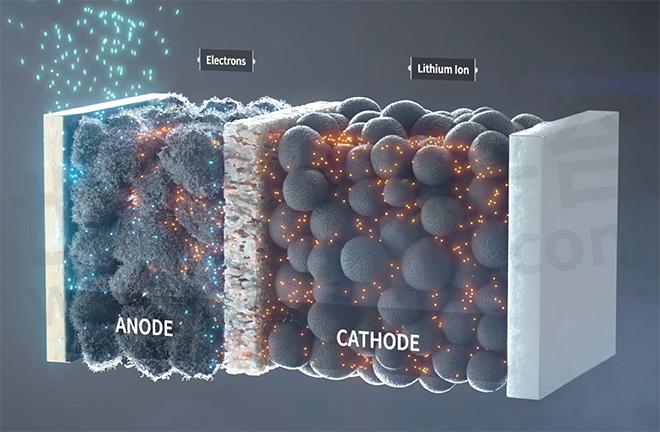

A silicon anode is a component of a lithium-ion battery where silicon is used as the primary material to store lithium ions during the battery's charge cycle. In the context of batteries, anodes are crucial as they serve as the site for the oxidation reaction during discharging and as the host for lithium ions during charging. Silicon, due to its high theoretical capacity to store lithium, has emerged as an attractive material for anodes.

What are Silicon Anode Lithium-Ion Batteries?

Silicon anode lithium-ion batteries are a type of rechargeable battery where silicon replaces the conventional graphite in the anode. These batteries aim to leverage the superior lithium storage capacity of silicon to achieve higher energy densities, thus offering potentially longer battery life and improved performance over traditional lithium-ion batteries.

Why is Silicon Used as an Anode?

Silicon is used as an anode material because of its exceptional theoretical capacity to store lithium ions. Silicon can hold approximately ten times more lithium than graphite, the traditional anode material. Specifically, silicon has a theoretical capacity of about 4200 mAh/g compared to graphite's 372 mAh/g. This substantial difference makes silicon a highly attractive material for enhancing the energy density of lithium-ion batteries.

What is the Difference Between Silicon and Lithium Anodes?

Silicon and lithium anodes differ primarily in their material properties and performance characteristics. While lithium metal anodes offer high energy density, they are prone to dendrite formation, which can cause short circuits and safety issues. Silicon anodes, on the other hand, provide a much higher capacity for lithium-ion storage than graphite but come with their own set of challenges, such as significant volume expansion during charging cycles.

Why is Silicon Anode Battery?

Silicon anodes are considered better than traditional graphite anodes due to their higher energy storage capacity. Using a silicon anode improves energy density by allowing the battery to store more lithium ions per unit weight compared to graphite anodes. This higher capacity translates to potentially longer-lasting batteries and the ability to store more energy in a given volume, making them particularly attractive for applications requiring high energy density, such as electric vehicles and portable electronics. For electric vehicles, this translates to longer driving ranges on a single charge, and for consumer electronics, it means longer usage times between charges.

What are the Advantages of Silicon Anode Batteries?

●Higher Energy Density: Silicon anodes can significantly increase the energy density of lithium-ion batteries, enabling longer-lasting batteries.

●Improved Performance: Higher capacity means better performance, especially in applications requiring high power outputs.

●Potential for Reduced Costs: With increased energy density, fewer cells may be needed to achieve the desired capacity, potentially reducing the overall cost of battery packs.

What are the Disadvantages of Silicon Anode Batteries?

●Volume Expansion: The substantial volume change during lithiation can cause mechanical degradation and capacity loss.

●Cycle Life: The mechanical stress and SEI layer formation can lead to a reduced cycle life compared to graphite anodes.

●Manufacturing Challenges: Incorporating silicon into anodes requires advanced manufacturing techniques and materials engineering to mitigate the expansion issues, potentially increasing production complexity and cost.

Conclusion

Silicon anode lithium-ion batteries represent a significant advancement in battery technology, promising higher energy densities and improved performance over traditional graphite-based batteries. However, the challenges associated with silicon's volume expansion and the resulting mechanical stress need to be addressed to fully realize their potential. Ongoing research and development efforts are focused on overcoming these obstacles, paving the way for the next generation of high-performance, long-lasting batteries. As these technologies mature, silicon anode batteries are likely to play a crucial role in the future of energy storage, particularly in high-demand applications. As a global leading lipo battery manufacturer, Grepow's NMC battery cells use silicon-carbon as the anode, achieving an energy density of 350Wh/kg, which can meet various high energy density requirements.

- +1 Like

- Add to Favorites

Recommend

- Silicon Labs Simplifies IoT Development with Simplicity Studio 5

- Silicon Labs Z-Wave Wireless Selected for Johnson Controls Next Generation Qolsys Smart Home Panel

- Silicon Labs Strengthens Isolated Gate Driver Portfolio

- News | Silicon Labs and Amazon Collaborate on Sidewalk, a New Shared Network for IoT Consumer Devices

- Silicon Labs Expands Isolated Gate Driver Product Family Ideal for Hybrid and Electric Vehicles (EV)

- Software Speeds Development of IEEE 1588 System Integration | Silicon Labs

- Silicon Labs and Skyworks reach agreement to sell infrastructure and automotive business

- What is a Smart Ring Battery and The Manufacturing Process?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.